In the dynamic landscape of industrial chemicals, polyvinyl alcohol (PVA) stands as a versatile and widely - utilized polymer. Understanding the polyvinyl alcohol cas no (CAS Number: 9002 - 89 - 5) and adhering to appropriate storage guidelines is not only crucial for maintaining the quality of PVA but also for ensuring its safe handling and effective use across various industries. Shijiazhuang Yaguan New Material Technology Co., Ltd., a leading manufacturer and supplier of PVA, recognizes the significance of proper storage and is committed to providing high - quality PVA that meets the strictest standards when stored correctly. This article, from the perspective of a wholesaler, delves into the detailed storage guidelines for PVA, integrating its unique properties, diverse applications, and the expertise of Shijiazhuang Yaguan New Material Technology Co., Ltd.

Polyvinyl Alcohol Cas No: A Key to Regulatory and Quality Assurance

The polyvinyl alcohol cas number (9002 - 89 - 5) serves as a universal identifier for PVA in the global chemical market. This number is essential for regulatory compliance, as it helps authorities track the movement, use, and storage of PVA. For Shijiazhuang Yaguan New Material Technology Co., Ltd., the poly vinyl alcohol cas number is the starting point for ensuring that all aspects of PVA production, distribution, and storage meet the required standards.

PVA Properties Influencing Storage

PVA has several properties that directly impact its storage requirements:

- Water Solubility: PVA-Pulver kann in Wasser aufgelöst werden, making it highly sensitive to moisture. This property necessitates strict control over humidity levels during storage to prevent clumping, degradation, and changes in its physical and chemical properties.

- Thermal Stability: PVA softens when heated, which means that temperature control is crucial. Exposure to high temperatures can lead to changes in its viscosity, melting, and even decomposition in extreme cases.

- Chemical Resistance: While PVA is almost unaffected by weak acids, weak bases, and many organic solvents, it still needs to be stored away from strong reactive chemicals that could potentially alter its structure or properties.

- Film - Forming Properties: Due to its high adhesion between molecules, PVA is easy to form a film. This property can be affected by improper storage, leading to a loss of film - forming quality, which is essential for many of its applications.

Table: PVA Properties and Their Storage Implications

|

Property |

Details |

Storage Implication |

|

Water Solubility |

PVA-Pulver kann in Wasser aufgelöst werden |

Maintain low humidity levels; use moisture - proof packaging to prevent moisture ingress |

|

Thermal Stability |

Softens when heated |

Store in a temperature - controlled environment within the recommended range |

|

Chemical Resistance |

Unaffected by weak acids, bases, and many organic solvents |

Keep away from strong reactive chemicals |

|

Film - Forming Properties |

High adhesion between molecules enables easy film formation |

Ensure storage conditions do not compromise molecular structure and adhesion |

Optimal Storage Environment for Polyvinyl Alcohol cas no

Temperature Control

The thermal stability of PVA dictates that it should be stored in a cool and dry place. Shijiazhuang Yaguan New Material Technology Co., Ltd. recommends a storage temperature range of 10°C - 30°C. Temperatures above 30°C can cause PVA to soften, leading to agglomeration and changes in its flow properties. On the other hand, extremely low temperatures can make the PVA powder brittle and may also affect its solubility when later dissolved in water. By maintaining the temperature within the optimal range, wholesalers can ensure that the PVA retains its intended properties for use in applications such as textile sizing, paper coatings, and adhesives.

Humidity Management

Given the water - soluble nature of PVA, humidity is one of the most critical factors to control during storage. The storage area should have a relative humidity of less than 60%. High humidity can cause PVA to absorb moisture from the air, resulting in clumping, mold growth, and a decrease in its effectiveness. Shijiazhuang Yaguan New Material Technology Co., Ltd. packages PVA in moisture - resistant materials, such as sealed plastic bags or containers with tight - fitting lids. Wholesalers should ensure that these packages remain unopened until ready for use and store them on pallets or shelves to prevent direct contact with the floor, which may be more prone to moisture.

Light and Air Exposure

PVA should be stored away from direct sunlight and excessive air exposure. Ultraviolet (UV) light from sunlight can degrade the polymer chains in PVA, leading to a loss of its physical and chemical properties over time. Additionally, prolonged exposure to air can cause oxidation, which may affect the color, solubility, and performance of PVA. Storing PVA in opaque containers or in areas with limited light penetration and using airtight packaging can significantly reduce the impact of light and air on the quality of PVA.

Packaging and Handling of Polyvinyl Alcohol cas no

Packaging Materials

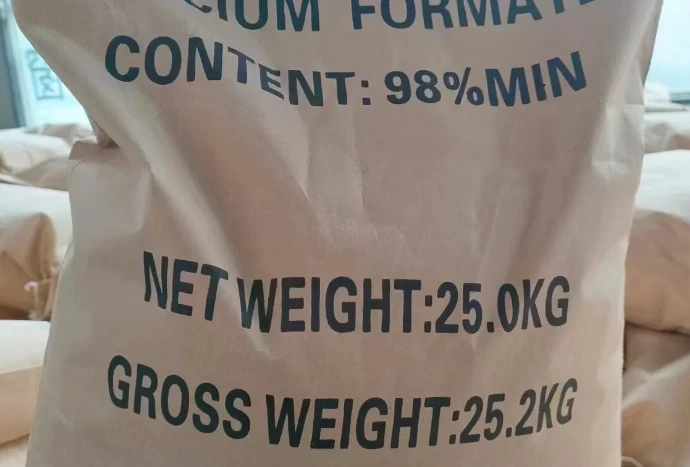

Shijiazhuang Yaguan New Material Technology Co., Ltd. uses high - quality packaging materials to ensure the integrity of PVA during storage and transportation. For small - scale packaging, multi - layer plastic bags are commonly used. These bags provide excellent moisture resistance and can be sealed tightly to prevent any external contaminants from entering. For bulk storage, large - capacity fiber drums or plastic containers are employed. These containers are robust and can withstand the rigors of handling and transportation while maintaining the dry and protected environment required for PVA.

Handling Precautions

When handling PVA, it is essential to avoid any actions that could damage the packaging. Rough handling, such as dropping or dragging the containers, can lead to tears or breaks in the packaging, exposing the PVA to moisture and contaminants. Forklifts or pallet jacks should be used to move heavy containers of PVA, and care should be taken to ensure that the containers are stacked properly to prevent tipping or crushing. Additionally, personnel handling PVA should wear appropriate protective gear, such as gloves and masks, to prevent any potential skin or respiratory contact with the powder.

Compatibility and Segregation in Polyvinyl Alcohol cas number Storage

Chemical Compatibility

Although PVA has good chemical resistance to many substances, it should not be stored in close proximity to strong oxidizing agents, strong acids, or strong bases. These chemicals can react with PVA and cause degradation or changes in its properties. For example, strong oxidizing agents can break the polymer chains in PVA, leading to a loss of its viscosity and film - forming ability. Shijiazhuang Yaguan New Material Technology Co., Ltd. advises wholesalers to store PVA in a separate area from such reactive chemicals to ensure its safety and quality.

Grade and Application - Based Segregation

PVA comes in different grades, each with specific properties tailored for different applications. For instance, PVA grades with high viscosity are often used in adhesives, while those with lower viscosity may be more suitable for textile sizing. Wholesalers should segregate PVA based on its grade and intended application to prevent confusion and ensure that customers receive the correct product. Clearly labeling the storage areas and containers with information about the PVA grade, polyvinyl alcohol cas number, and application can help streamline the distribution process and avoid costly mistakes.

Polyvinyl Alcohol Cas No FAQS

What are the consequences of improper storage of polyvinyl alcohol cas number with respect to its cas number?

Improper storage of polyvinyl alcohol (with cas number 9002 - 89 - 5) can lead to significant quality degradation. Exposure to high humidity can cause the water - soluble PVA to clump, affecting its solubility and performance in applications. High temperatures can soften the PVA, altering its physical properties such as viscosity. These changes can render the PVA unsuitable for its intended use, whether it's in textile sizing, paper coatings, or adhesives. Additionally, improper storage may lead to chemical reactions if PVA is exposed to incompatible substances, which can also change its properties and make it non - compliant with the standards associated with its polyvinyl alcohol cas no. Shijiazhuang Yaguan New Material Technology Co., Ltd. emphasizes that adhering to proper storage guidelines is essential to maintain the quality and integrity of PVA linked to its specific cas number.

How does the polyvinyl alcohol cas number influence storage regulations?

The polyvinyl alcohol cas number (9002 - 89 - 5) serves as a reference for regulatory bodies around the world to establish storage regulations. Based on the properties associated with this cas number, regulations may specify requirements such as temperature and humidity control, packaging materials, and segregation from other chemicals. For example, because PVA is water - soluble (PVA-Pulver kann in Wasser aufgelöst werden) and has certain thermal stability characteristics indicated by its cas number - related properties, regulatory authorities may mandate storage in cool, dry environments with proper moisture - proof packaging. Shijiazhuang Yaguan New Material Technology Co., Ltd. ensures that its PVA products comply with these regulations by following strict storage guidelines during production, distribution, and recommendation to wholesalers.

Can different grades of polyvinyl alcohol cas number with the same cas number be stored together?

While different grades of polyvinyl alcohol share the same polyvinyl alcohol cas number (9002 - 89 - 5), they should not be stored together. Each grade of PVA has specific properties, such as viscosity, degree of polymerization, and alcoholysis, which are tailored for different applications. Storing different grades together can lead to cross - contamination, making it difficult to ensure the consistency and quality of the product. For example, a high - viscosity PVA grade intended for adhesives may be affected if mixed with a low - viscosity grade meant for textile sizing. Wholesalers should segregate PVA grades to maintain product integrity and meet the specific requirements of their customers, even though all grades are identified by the same poly vinyl alcohol cas. Shijiazhuang Yaguan New Material Technology Co., Ltd. provides clear labeling and guidance to help wholesalers with proper grade segregation.

What role does Shijiazhuang Yaguan New Material Technology play in ensuring polyvinyl alcohol cas no storage compliance?

Shijiazhuang Yaguan New Material Technology Co., Ltd. plays a crucial role in ensuring polyvinyl alcohol storage compliance. The company starts by producing high - quality PVA that meets the standards associated with its polyvinyl alcohol cas number. It then provides detailed storage guidelines to wholesalers, including information on temperature, humidity, packaging, and segregation. The company uses appropriate packaging materials that are designed to protect PVA during storage and transportation. Additionally, Shijiazhuang Yaguan New Material Technology Co., Ltd. conducts regular quality checks to ensure that its PVA products maintain their integrity even after storage. By doing so, the company helps wholesalers comply with regulatory requirements and deliver high - quality PVA to end - users.

How can wholesalers verify the authenticity of polyvinyl alcohol cas number based on its cas number during storage?

Wholesalers can verify the authenticity of polyvinyl alcohol based on its polyvinyl alcohol cas number (9002 - 89 - 5) during storage by checking the product documentation provided by Shijiazhuang Yaguan New Material Technology Co., Ltd. This documentation typically includes information about the product's origin, manufacturing process, and quality control measures. Additionally, wholesalers can perform basic quality checks, such as inspecting the appearance of the PVA powder (it should be white or slightly yellowish, free - flowing, and without clumps), and comparing its physical properties (such as solubility in water, as PVA-Pulver kann in Wasser aufgelöst werden) with the expected values for PVA with the given cas number. By cross - referencing these factors, wholesalers can ensure that the PVA they are storing and distributing is authentic and of high quality.

Proper storage of polyvinyl alcohol guided by its polyvinyl alcohol cas number (9002 - 89 - 5) is essential for maintaining its quality, ensuring regulatory compliance, and meeting the diverse needs of various industries. Shijiazhuang Yaguan New Material Technology Co., Ltd. plays a vital role in this process by providing high - quality PVA, detailed storage guidelines, and reliable support to wholesalers. By controlling factors such as temperature, humidity, light exposure, and ensuring proper packaging, handling, and segregation, wholesalers can safeguard the integrity of PVA. This not only benefits the end - users who rely on PVA for applications ranging from textile and paper manufacturing to construction and adhesives but also contributes to the efficient and sustainable operation of the chemical supply chain. As the demand for PVA continues to grow, adherence to these storage guidelines will remain crucial for all stakeholders involved in its production, distribution, and use.

Durchlässig

Nächste