Introduction to Fibra di polipropilene (PP Fiber)

In the realm of advanced material engineering, Fibra di polipropilene stands as a critical component, renowned for its versatile properties and widespread industrial adoption. Derived from polypropylene, a thermoplastic polymer, these fibers are engineered to enhance the performance and durability of various composites and end-products. Their exceptional chemical resistance, high tensile strength, and hydrophobic nature make them indispensable in sectors ranging from construction and textiles to filtration and automotive. This article delves into the intricate details of PP fiber, covering its manufacturing processes, technical specifications, diverse applications, and strategic advantages for B2B stakeholders.

The demand for high-performance, cost-effective materials continues to drive innovation, and PP fiber consistently meets these evolving requirements. Its ability to impart crack resistance, impact strength, and abrasion resistance makes it a superior choice over conventional reinforcement methods in numerous challenging environments. We will explore the market trends shaping its future, detailed technical parameters, and provide actionable insights for businesses seeking to leverage this advanced material.

Manufacturing Process Flow of Fibra di polipropilene

The production of Fibra di polipropilene involves a sophisticated series of stages, meticulously controlled to achieve desired physical and chemical properties. The process typically begins with high-grade polypropylene pellets, which serve as the primary raw material. These pellets undergo a melt-spinning extrusion process, followed by drawing, finishing, and cutting.

- Material Preparation: High-purity polypropylene resin pellets are fed into a hopper. Additives such as UV stabilizers, flame retardants, and colorants may be incorporated at this stage to impart specific characteristics to the final fiber.

- Melting and Extrusion: The pellets are melted in an extruder at temperatures typically ranging from 200°C to 280°C. The molten polymer is then forced through a spinneret – a die with multiple fine holes – creating continuous filaments. The design of the spinneret, including hole diameter and shape, dictates the fiber's cross-sectional geometry.

- Quenching (Cooling): Immediately after extrusion, the hot filaments are rapidly cooled, often by a stream of air, to solidify them. This step is crucial for controlling the nascent fiber’s molecular orientation and crystallization.

- Drawing/Stretching: The solidified fibers are then stretched, or drawn, through a series of heated rollers. This mechanical drawing process aligns the polymer molecules along the fiber axis, significantly increasing tensile strength, modulus, and reducing elongation. The draw ratio (the ratio of the final length to the original length) is a critical parameter influencing the fiber's mechanical properties.

- Finishing and Crimping: A finish (e.g., lubricating agent, antistatic agent) is applied to the fibers to improve processability and end-use performance. For staple fibers, crimping is performed to impart bulk and texture, enhancing their ability to interlock in matrices like concrete or nonwovens.

- Cutting and Packaging: Finally, the continuous filaments are cut into desired lengths, ranging from short staple fibers for concrete reinforcement to longer lengths for geotextiles. The fibers are then packaged for distribution.

Throughout this process, stringent quality control measures are implemented. Testing standards, such as those prescribed by ISO (e.g., ISO 2062 for textile fibers – determination of linear density, ISO 5079 for breaking force and elongation) and ASTM (e.g., ASTM D3822 for breaking tenacity), ensure that the final Fibra di polipropilene meets specified performance criteria. The typical service life of PP fibers, especially when incorporated into durable goods like concrete or geotextiles, can exceed 50 years under proper conditions, attributed to their inherent chemical inertness and resistance to biological degradation. Target industries include petrochemical (for filtration), metallurgy (for reinforcement), and water supply & drainage (for pipe reinforcement and geotextiles).

Figure 1: Schematic of the Fibra di polipropilene manufacturing process.

Industry Trends and Market Dynamics for Fibra di polipropilene

The market for Fibra di polipropilene is experiencing robust growth, driven by increasing infrastructure development globally, particularly in emerging economies. Key trends indicate a rising demand for durable, lightweight, and cost-effective construction materials. The shift towards sustainable and energy-efficient building practices also favors PP fibers, as they contribute to extending material lifespan and reducing maintenance needs.

- Construction Sector Growth: As a primary reinforcement material in concrete, mortar, and asphalt, PP fiber demand is intrinsically linked to the booming construction industry. Its ability to mitigate plastic shrinkage cracking and improve freeze-thaw resistance is highly valued.

- Geotextiles and Environmental Applications: Increasing regulatory emphasis on soil stabilization, erosion control, and landfill lining fuels the demand for PP fibers in geotextiles due to their excellent resistance to chemicals, rot, and mildew.

- Automotive and Lightweighting: The automotive industry uses PP fibers in nonwoven composites for interior components, offering weight reduction and improved acoustic properties, aligning with stricter fuel efficiency standards.

- Technological Advancements: Continuous innovation in fiber modification, such as surface treatments and engineered cross-sections, is expanding application possibilities and enhancing performance, leading to higher-value products.

The market is also seeing a push for higher-performance PP fibers, including macro synthetic fibers that can partially or fully replace steel mesh in specific concrete applications, offering advantages in handling and corrosion resistance. The global PP fiber market size was valued at approximately USD 6.5 billion in 2022 and is projected to grow at a CAGR of 5-7% from 2023 to 2030, according to various market research reports, underscoring its pivotal role in future industrial development.

Technical Specifications and Performance Parameters of Fibra di polipropilene

Understanding the precise technical specifications of Fibra di polipropilene is crucial for engineers and procurement specialists to ensure optimal material selection for specific applications. PP fibers exhibit a unique combination of mechanical, chemical, and thermal properties that distinguish them from other synthetic fibers.

Key Product Specifications

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Material | 100% Virgin Polypropylene | Ensures consistent quality, purity, and performance without recycled material impurities. |

| Type | Monofilament, Fibrillated Mesh, Multifilament | Varies based on application; monofilament for crack control, mesh for higher tensile, multifilament for general reinforcement. |

| Fiber Length | 3mm - 19mm (typical for concrete); up to 150mm+ (for geotextiles) | Critical for proper dispersion and reinforcement efficacy in different matrices. |

| Diameter/Equivalent Diameter | 10-40 microns (monofilament); 0.3-0.5mm (fibrillated) | Influences surface area, bonding with matrix, and overall mechanical contribution. |

| Tensile Strength | 300-600 MPa | Resistance to breaking under tension, vital for reinforcement applications. |

| Elastic Modulus | 3.5-7.0 GPa | Measure of stiffness; higher modulus means less deformation under stress. |

| Elongation at Break | 15-30% | Indicates the fiber's ductility and ability to absorb energy before failure. |

| Specific Gravity | 0.90-0.91 g/cm³ | Extremely lightweight, allowing for excellent dispersion without segregation in mixes. |

| Melting Point | 160-170°C | Defines temperature limits for processing and high-temperature applications. |

| Acid/Alkali Resistance | Excellent | Crucial for durability in harsh chemical environments, such as concrete. |

| Water Absorption | Negligible (<0.1%) | Hydrophobic nature prevents moisture-induced degradation and ensures dimensional stability. |

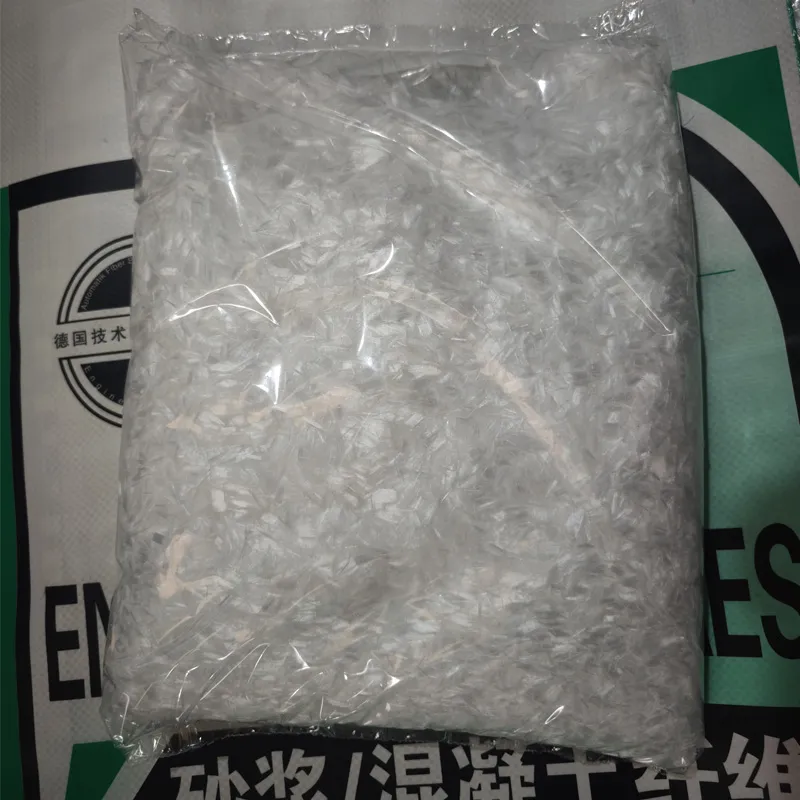

These parameters highlight why Fibra di polipropilene is a preferred choice. For instance, its low specific gravity ensures uniform distribution in concrete, preventing settlement, while its high chemical resistance guarantees long-term performance in corrosive environments. The varying fiber lengths and types (monofilament, fibrillated, macro-synthetic) are designed to target specific reinforcement mechanisms, from microscopic crack control to macroscopic structural enhancement.

Figure 2: Microscopic view of Fibra di polipropilene, illustrating its structural integrity.

Application Scenarios Across Diverse Industries for Fibra di polipropilene

The versatility of Fibra di polipropilene allows it to be integrated into an extensive array of industrial and commercial applications, delivering significant performance enhancements. Its attributes are particularly beneficial in environments demanding durability, chemical inertness, and structural integrity.

-

Construction & Infrastructure:

- Concrete & Mortar Reinforcement: Used in slabs, precast elements, shotcrete, and screeds to control plastic shrinkage and settlement cracking, reduce permeability, and improve impact resistance and toughness. Exemplifies energy saving through reduced material waste and extended structural life.

- Roads & Pavements: Incorporated into asphalt mixes to improve fatigue resistance, rutting resistance, and extend pavement service life, especially in extreme temperatures.

- Geotextiles & Geomembranes: For soil stabilization, erosion control, drainage, and filtration in civil engineering projects, landfills, and coastal protection due to excellent corrosion resistance and UV stability.

-

Textiles & Nonwovens:

- Technical Textiles: In ropes, nets, industrial fabrics, and protective clothing where high strength-to-weight ratio and chemical resistance are paramount.

- Filtration Media: Due to its hydrophobic nature and chemical resistance, PP fiber is ideal for air, liquid, and gas filtration in industrial processes, medical applications, and HVAC systems.

-

Automotive:

- Interior & Exterior Components: Used in composites for car interiors (carpets, headliners) and specific exterior parts, offering lightweight solutions, improved impact resistance, and sound dampening.

-

Agriculture:

- Crop Covers & Netting: Provides protection against pests and harsh weather, while being durable and UV-resistant.

Each application leverages specific characteristics of PP fiber, from its inherent resistance to alkalis in cementitious matrices to its low density in lightweight composites. This adaptability makes it a material of choice for engineers seeking innovative and reliable solutions.

Figure 3: Fibra di polipropilene enhancing concrete durability in construction projects.

Technical Advantages of Using Fibra di polipropilene

The widespread adoption of Fibra di polipropilene in demanding industrial applications is a testament to its compelling technical advantages. These benefits translate directly into enhanced product performance, increased longevity, and improved cost-effectiveness for B2B clients.

- Superior Crack Resistance: PP fibers effectively control plastic shrinkage and settlement cracking in concrete and mortar. By providing a distributed reinforcement network, they significantly reduce the propagation of micro-cracks, thereby improving the material's durability and integrity.

- Enhanced Impact and Abrasion Resistance: The presence of PP fibers increases the material's ability to absorb energy, leading to higher impact strength and resistance to surface wear. This is crucial for flooring, industrial pavements, and precast elements subjected to heavy loads or abrasive conditions.

- Exceptional Chemical and Corrosion Resistance: Unlike metallic reinforcements, PP fibers are completely inert to alkalis, acids, and salts found in concrete and various industrial environments. This inherent corrosion resistance ensures long-term performance without degradation, making them ideal for aggressive chemical exposures and marine structures.

- Hydrophobic Nature & Freeze-Thaw Resistance: PP fibers do not absorb water, which prevents internal ice formation and subsequent damage during freeze-thaw cycles. This contributes significantly to the longevity of outdoor concrete structures and pavements in cold climates.

- Lightweight and Easy Dispersion: With a specific gravity less than water, PP fibers are extremely lightweight, facilitating easy handling and ensuring uniform dispersion throughout a matrix without segregation. This simplifies mixing processes and contributes to the overall efficiency of material production.

- Energy Saving & Sustainability: By extending the service life of structures and reducing the need for costly repairs and replacements, PP fibers contribute to overall energy savings and reduced resource consumption. Their long-term durability aligns with sustainable construction practices.

- Fire Resistance Improvement (Specific Formulations): While PP itself melts at relatively low temperatures, specialized fire-resistant PP fibers or those designed to melt and create escape routes for steam in concrete can improve spalling resistance in fire events, an essential property for tunnels and high-rise buildings.

These advantages collectively position PP fiber as a highly effective and economical solution for enhancing the performance and durability of a wide range of materials and products.

Vendor Comparison: Choosing the Right Fibra di polipropilene Supplier

Selecting the optimal supplier for Fibra di polipropilene is critical for ensuring consistent product quality, timely delivery, and tailored solutions that meet specific project requirements. A comprehensive vendor comparison should evaluate several key aspects beyond just price.

Key Comparison Criteria

| Criteria | Leading Supplier (e.g., Yaguan HPMC) | Generic Supplier (Hypothetical) | Importance |

|---|---|---|---|

| Product Quality & Consistency | High-grade virgin PP, tight tolerance control, ISO 9001 certified manufacturing. | Variable quality, often uses recycled content, less stringent controls. | Ensures predictable performance and avoids project failures. |

| Technical Support & Expertise | Dedicated engineering team, application guidance, formulation advice. | Limited technical assistance, basic product data sheets. | Crucial for optimizing fiber use and troubleshooting specific challenges. |

| Customization Capabilities | Offers custom fiber lengths, deniers, surface treatments, packaging. | Standard product lines only, no flexibility. | Allows for optimized solutions for unique project requirements. |

| Certifications & Compliance | ISO, CE, ASTM, local building code compliance, comprehensive test reports. | Few or no internationally recognized certifications. | Verifies product reliability and adherence to industry standards, essential for regulatory compliance. |

| Lead Time & Supply Chain Reliability | Robust global logistics, buffer stock, accurate lead time estimates (e.g., 2-4 weeks). | Inconsistent delivery, limited stock, potential delays. | Minimizes project delays and ensures uninterrupted operations. |

| Post-Sales Support & Warranty | Dedicated support, clear warranty (e.g., 12 months), responsive issue resolution. | Limited or no warranty, slow response to post-purchase issues. | Provides peace of mind and safeguards investment. |

Choosing a reputable vendor like Yaguan HPMC, with a proven track record (e.g., 20+ years in the industry), strong certifications, and a commitment to quality, significantly reduces project risks and optimizes long-term value. Clients such as major construction firms and infrastructure developers frequently prioritize suppliers that can demonstrate robust quality control and comprehensive technical support.

Figure 4: Quality control inspection of Fibra di polipropilene before dispatch.

Customized Solutions for Fibra di polipropilene

Recognizing that every project presents unique challenges, leading manufacturers of Fibra di polipropilene offer bespoke solutions tailored to specific application demands. This customization capability is crucial for B2B clients who require materials optimized for distinct performance criteria or complex environmental conditions.

Customization options typically include variations in:

- Fiber Length and Denier: Tailoring fiber length and thickness (denier) to suit specific mix designs for concrete (e.g., shorter fibers for thin screeds, longer for mass concrete) or nonwoven fabric structures.

- Fiber Type (Monofilament, Fibrillated, Macro-Synthetic): Selecting the appropriate fiber geometry to achieve desired properties, such as monofilament for basic crack control, fibrillated for enhanced matrix adhesion, or macro-synthetic for structural reinforcement.

- Surface Treatments: Applying coatings or surface modifications to enhance adhesion to specific matrices (e.g., improved bond with polymer-modified mortars) or to impart additional properties like hydrophilicity/hydrophobicity.

- Additives and Colorants: Integrating UV stabilizers for outdoor applications, flame retardants for fire-critical uses, anti-bacterial agents, or custom colorants for aesthetic or identification purposes.

- Packaging: Offering various packaging formats, from small dissolvable bags for easy dosing at job sites to bulk bags for large-scale industrial use, optimizing logistical efficiency.

Through a collaborative approach, manufacturers can work with clients to analyze project specifications, conduct material testing, and develop custom PP fiber formulations that precisely meet performance objectives, ensuring optimal outcomes and cost efficiency.

Application Case Studies & Customer Successes

The practical utility and robust performance of Fibra di polipropilene are best demonstrated through real-world application case studies and testimonials from satisfied clients. These examples highlight how PP fiber delivers tangible benefits in demanding environments.

Case Study 1: Industrial Warehouse Flooring

A major logistics company faced persistent issues with plastic shrinkage cracking and low impact resistance in their new industrial warehouse concrete flooring, leading to high maintenance costs.

- Solution: Incorporation of 6mm monofilament Fibra di polipropilene at a dosage of 0.9 kg/m³ into the concrete mix for a 20,000 m² floor slab.

- Outcome: The PP fibers significantly reduced the incidence of plastic shrinkage cracking by over 80%. Post-construction impact tests revealed a 25% improvement in energy absorption capacity, leading to a substantial reduction in wear and tear from heavy forklift traffic. The client reported enhanced operational efficiency and projected maintenance cost savings of 30% over a 10-year period.

Case Study 2: Coastal Erosion Control Project

A civil engineering firm required a durable and chemically inert material for geotextiles in a coastal erosion control project, protecting a new harbor development from tidal forces and saltwater corrosion.

- Solution: Specification of high-tensile, UV-stabilized Fibra di polipropilene-based nonwoven geotextiles for shoreline reinforcement and filtration layers beneath riprap.

- Outcome: After three years in service, the PP geotextiles exhibited no signs of chemical degradation or UV embrittlement, outperforming previously used natural fibers. The project successfully withstood several severe storms, demonstrating the PP fiber's superior corrosion resistance and long-term stability in harsh marine environments. The client praised the material's extended service life and minimal environmental impact.

Customer Feedback:

"Our partnership with Yaguan HPMC has been instrumental in enhancing our concrete formulations. Their Fibra di polipropilene consistently delivers the crack control and durability our projects demand, especially in high-stress applications. The technical support is exceptional."

— Project Manager, Leading Construction Contractor

Figure 5: Successfully installed concrete pavement reinforced with Fibra di polipropilene.

Frequently Asked Questions (FAQ) about Fibra di polipropilene

Q1: What are the primary benefits of using Fibra di polipropilene in concrete?

A1: The primary benefits include significant reduction of plastic shrinkage and settlement cracking, improved impact and abrasion resistance, enhanced freeze-thaw durability, and superior chemical resistance compared to traditional reinforcement. It also aids in reducing permeability and improving overall concrete toughness.

Q2: Can Fibra di polipropilene replace steel reinforcement?

A2: For crack control in non-structural concrete elements (e.g., slabs on grade, screeds, precast non-load-bearing elements), PP fibers can effectively replace secondary steel mesh. However, for primary structural reinforcement where high tensile strength and load-bearing capacity are required, macro-synthetic PP fibers can partially replace steel in certain applications, but typically, they are used in conjunction with or as a complement to structural steel for enhanced durability and crack control. Consult with a structural engineer for specific applications.

Q3: How does dosage affect the performance of Fibra di polipropilene?

A3: Dosage rates vary depending on the specific application and desired performance. Generally, higher dosages lead to more pronounced improvements in crack resistance, impact strength, and post-crack residual strength. Standard dosages for microfibers range from 0.6 kg/m³ to 1.5 kg/m³ for crack control, while macro-synthetic fibers may be used at higher rates, often from 2 kg/m³ to 9 kg/m³ for structural enhancement.

Q4: Is Fibra di polipropilene resistant to UV degradation?

A4: Standard polypropylene can degrade under prolonged UV exposure. However, high-quality PP fibers designed for outdoor applications, such as geotextiles, are manufactured with integrated UV stabilizers to provide excellent resistance to photodegradation, ensuring long-term performance in exposed environments.

Lead Time, Warranty & Customer Support

At Yaguan HPMC, we understand the critical importance of reliable logistics, product assurance, and responsive support for B2B operations.

- Lead Time & Fulfillment: Our standard lead time for most Fibra di polipropilene products is typically 2 to 4 weeks from order confirmation, depending on order volume and specific customization requirements. We maintain a robust inventory of popular specifications to facilitate quicker dispatch for urgent needs. Expedited shipping options are available upon request. Our global logistics network ensures efficient and reliable delivery to your project site.

- Warranty Commitments: Yaguan HPMC stands behind the quality of its Fibra di polipropilene products. We offer a comprehensive warranty covering manufacturing defects and ensuring that our products meet or exceed the specified technical parameters and industry standards (e.g., ISO, ASTM) for a period of 12 months from the date of purchase. Detailed warranty terms are available upon request.

- Dedicated Customer Support: Our team of technical experts and customer service professionals is committed to providing unparalleled support. From initial consultation and product selection to application guidance and post-sales assistance, we are available to address any inquiries. Clients can reach us via phone, email, or through our website's contact portal for prompt and knowledgeable assistance. We pride ourselves on building long-term partnerships through consistent quality and exceptional service.

Conclusion

Fibra di polipropilene represents a cornerstone material in modern engineering, offering a compelling blend of performance, durability, and cost-effectiveness across a myriad of industrial applications. Its ability to enhance material properties, resist harsh environments, and contribute to sustainable construction practices makes it an indispensable component for forward-thinking businesses. By understanding its detailed manufacturing process, technical specifications, and diverse application benefits, B2B decision-makers can confidently integrate PP fibers into their projects, ensuring superior outcomes and long-term value.

References

- ACI Committee 544. (2002). State-of-the-Art Report on Fiber Reinforced Concrete (ACI 544.1R-96). American Concrete Institute.

- Bentur, A., & Mindess, S. (2007). Fibre Reinforced Cementitious Composites. CRC Press.

- ASTM D3822/D3822M-14. (2014). Standard Test Method for Tensile Properties of Single Textile Fibers. ASTM International.

- ISO 2062:2009. (2009). Textiles – Yarns from packages – Determination of single-end breaking force and elongation at break using a constant rate of extension (CRE) tester. International Organization for Standardization.

- Fibre Reinforced Concrete: From Theory to Practice. (2019). RILEM Technical Committee 266-TDF.

Pervio