The Versatile Role of Redispersible Emulsion Powder in Industrial Applications

Release Time:

Feb 08,2025

Redispersible Emulsion Powder (REP), also known as Redispersible Polymer Powder (RDP), is an industrial-grade material that has revolutionized various manufacturing processes, particularly in the construction and adhesive industries.

Redispersible Emulsion Powder (REP), also known as Redispersible Polymer Powder (RDP), is an industrial-grade material that has revolutionized various manufacturing processes, particularly in the construction and adhesive industries.

1. The Essence of Redispersible Emulsion Powder

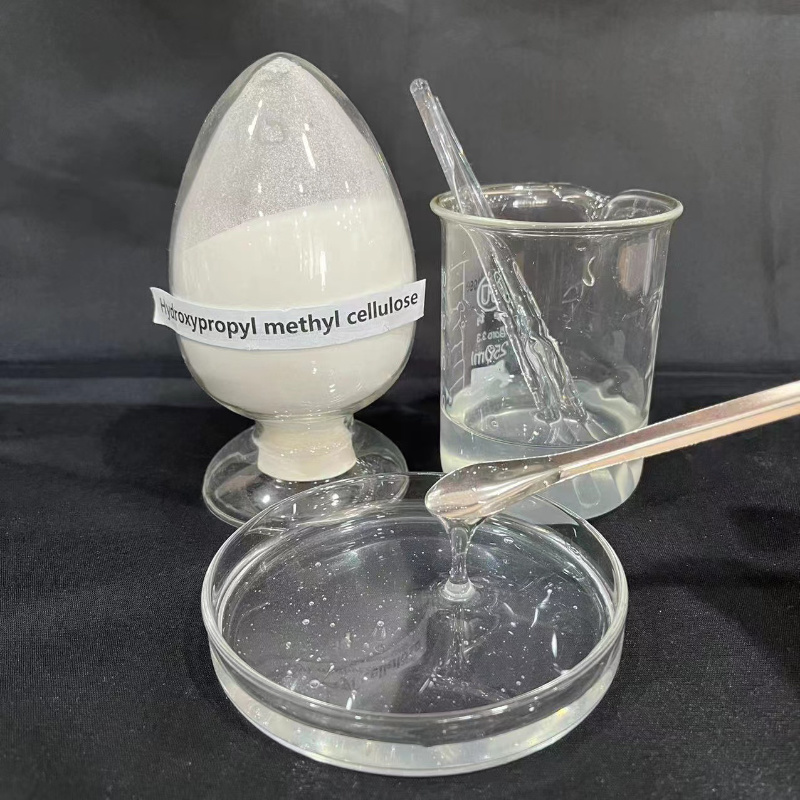

Redispersible Emulsion Powder is a water-soluble polymer powder produced through spray drying techniques, primarily from ethylene-vinyl acetate (EVA) copolymers. This powder can be redispersed in water to form an emulsion with properties similar to the original latex. Its unique ability to redisperse allows for easy incorporation into various formulations, enhancing the overall performance of the final product.

2. Versatility in Industrial Applications

One of the most compelling aspects of Redispersible Emulsion Powder is its versatility. It serves as a crucial functional additive in dry-mixed mortars, significantly improving the properties of these materials. In the construction industry, REP is widely used in the production of internal and external putties, ceramic tile adhesives, crack sealers, dry powder interfacial agents, and waterproof mortars. Its ability to enhance adhesion, flexibility, water-retention, and workability makes it indispensable in formulating high-performance mortars and adhesives.

3. Performance Enhancements in Industrial Products

The incorporation of Redispersible Emulsion Powder into industrial formulations leads to notable performance enhancements. It increases the strength and bond strength of mortars onto various substrates, improving their compressive strength, flexural strength, and wear resistance. Additionally, REP improves the flexibility and deformation capabilities of mortars, making them more resilient to environmental stresses. These performance enhancements translate into longer-lasting, more durable products that meet the rigorous demands of industrial applications.

Key words:

Latest news