One of the primary reasons short - staple fibers contribute to affordability is their widespread availability. Fibers like cotton, which often come in short - staple varieties, are abundant in nature. Their ease of cultivation and harvesting reduces production costs. Additionally, the manufacturing process for short - staple fiber - based fabrics is generally less complex. Spinning short - staple fibers into yarn requires less energy - intensive machinery compared to long - staple fibers. This simplicity in production further cuts down on expenses, allowing manufacturers to offer cost - effective fabric options to consumers.

When it comes to breathability, short - staple fibers excel. Their shorter length creates more air pockets within the fabric structure. For example, in a cotton T - shirt made from short - staple cotton fibers, these air pockets allow for better air circulation. As a person wears the garment, heat and moisture can escape more freely through these gaps, preventing overheating and discomfort. This makes short - staple fiber - based fabrics ideal for everyday wear, especially in warm climates.

Moreover, short - staple fibers can be blended with other types of fibers to enhance performance. For instance, a blend of short - staple cotton and synthetic fibers like polyester can create a fabric that combines the breathability of cotton with the durability and wrinkle - resistance of polyester. This versatility in blending further expands the range of affordable and breathable fabric options available in the market. In conclusion, short - staple fibers are the cornerstone of creating textiles that balance cost - effectiveness and comfort, meeting the demands of a wide range of consumers.

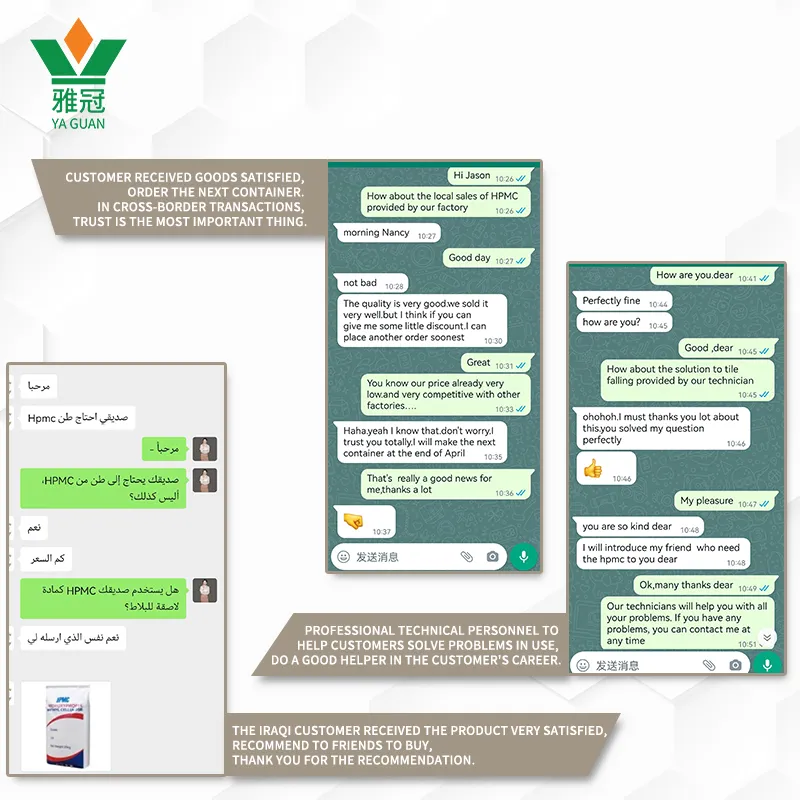

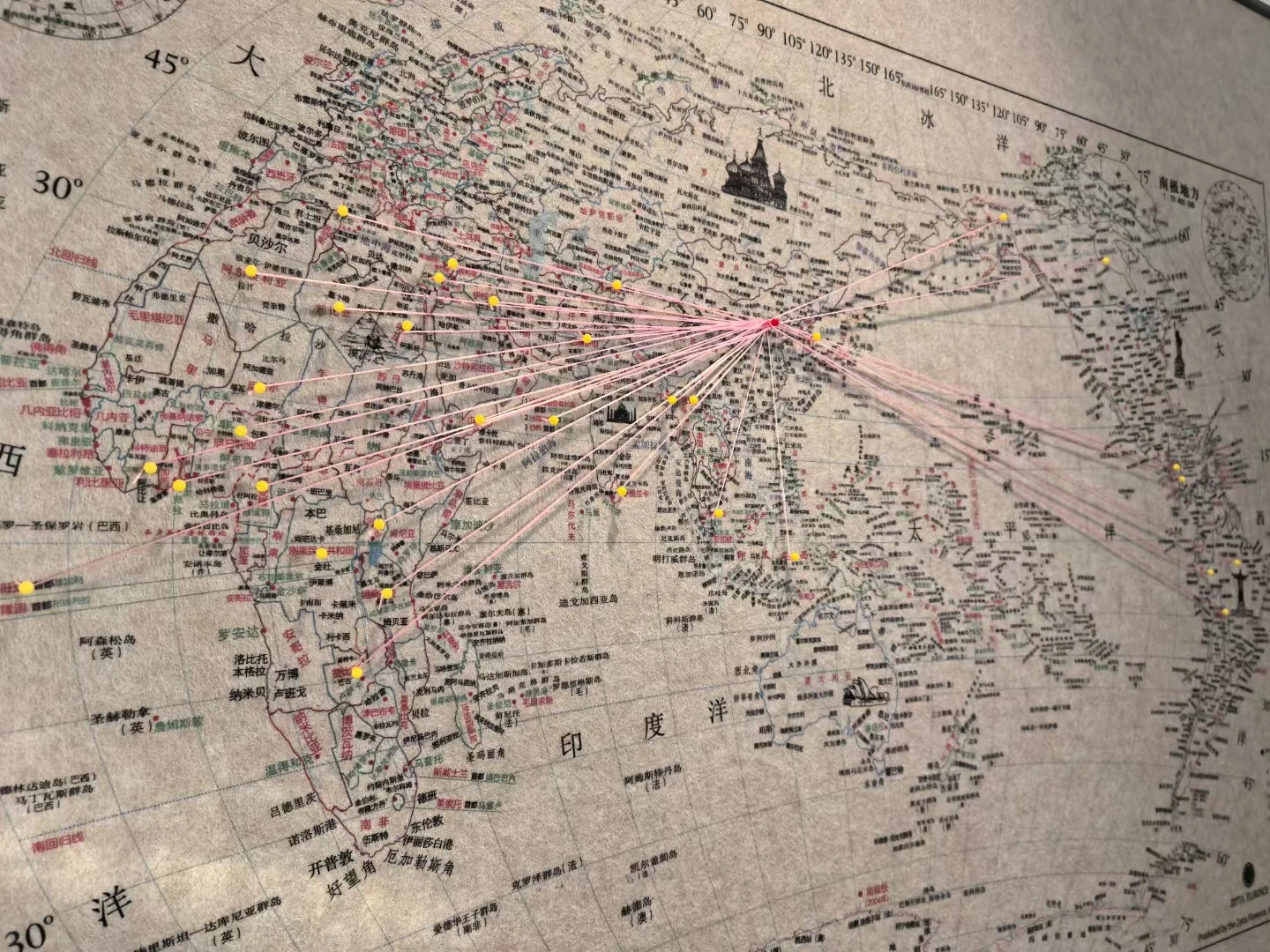

Our Partners

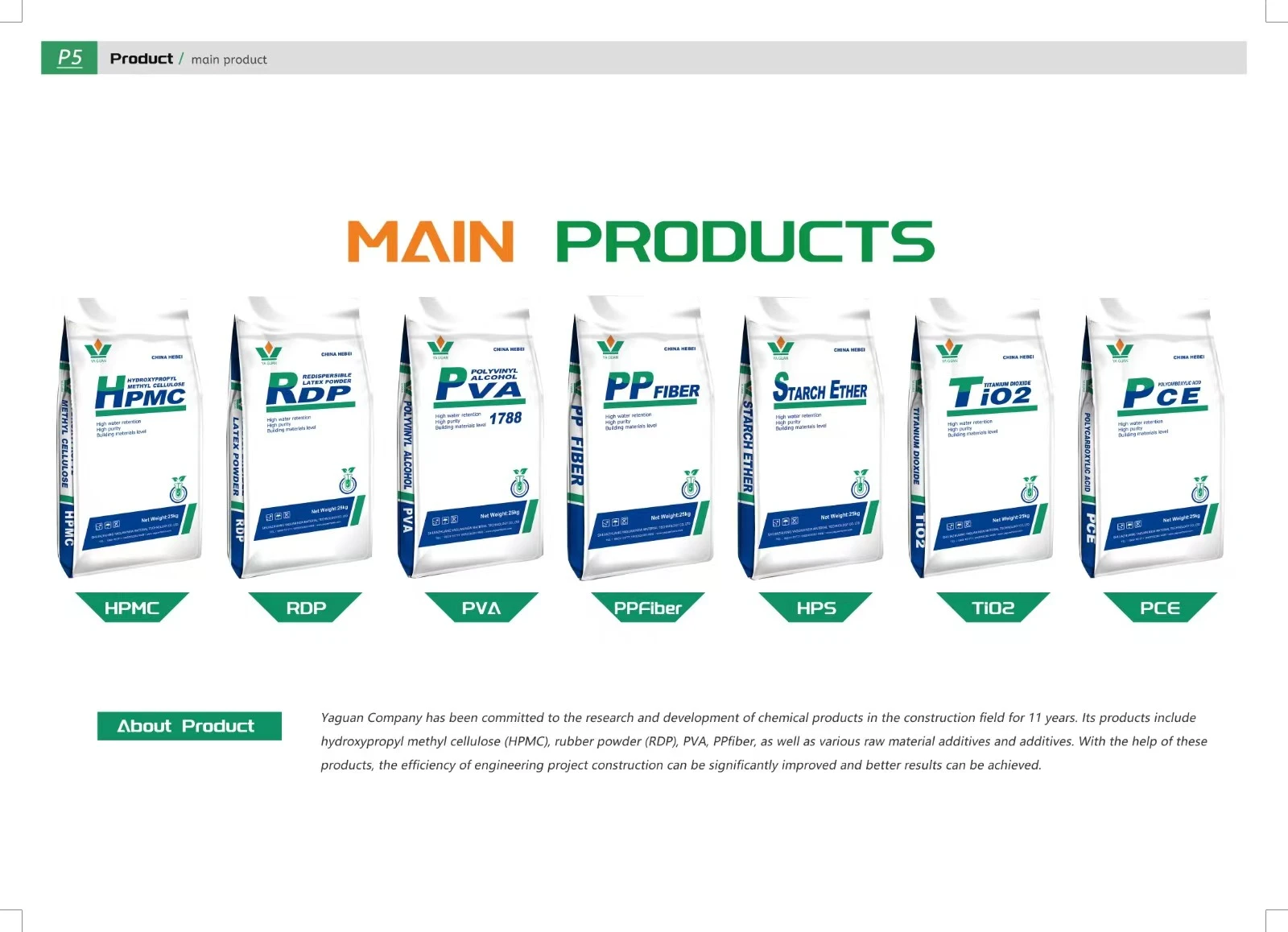

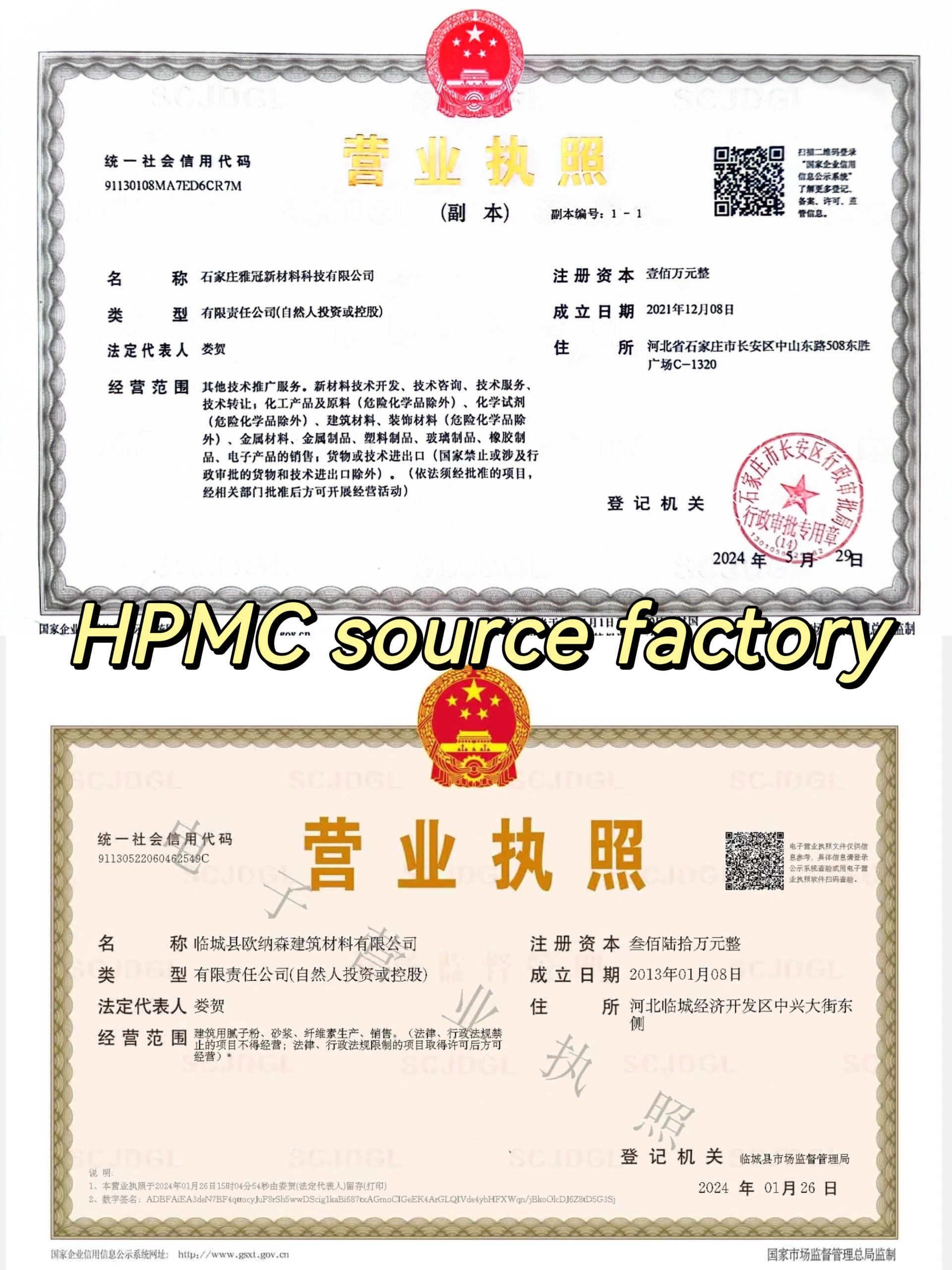

Shijiazhuang Yaguan New Material Technology Co., Ltd. is een industriële en handelsintegrerende onderneming met een grote expertise in onderzoek, ontwikkeling, productie, verkoop en service van vezeletherproducten.