In dry cleaning, PCE is a go - to solvent. Many fabrics, like delicate silk and wool, can't withstand traditional water - based cleaning methods. PCE steps in as a savior. It has an affinity for a wide array of substances, from oil - based stains to stubborn grime. Its non - polar molecular structure allows it to break down and dissolve these non - water - soluble contaminants. When garments are immersed in PCE during the dry cleaning process, the solvent quickly penetrates the fabric, loosening and removing the stains without causing damage. After cleaning, PCE can be easily separated from the garments through distillation, ensuring a residue - free finish.

As a degreaser, PCE is equally impressive. In industrial settings, machinery and equipment accumulate thick layers of grease over time. PCE can swiftly cut through this grease. For instance, in automotive workshops, it is used to clean engine parts. The solvent's ability to emulsify and disperse grease makes it possible to remove even the most tenacious deposits. This not only restores the equipment's performance but also extends its lifespan. PCE's low evaporation rate during the degreasing process means that it remains potent, allowing for efficient and thorough cleaning. Overall, PCE's role in dry cleaning and degreasing is vital, enabling both the care of precious fabrics and the maintenance of industrial machinery.

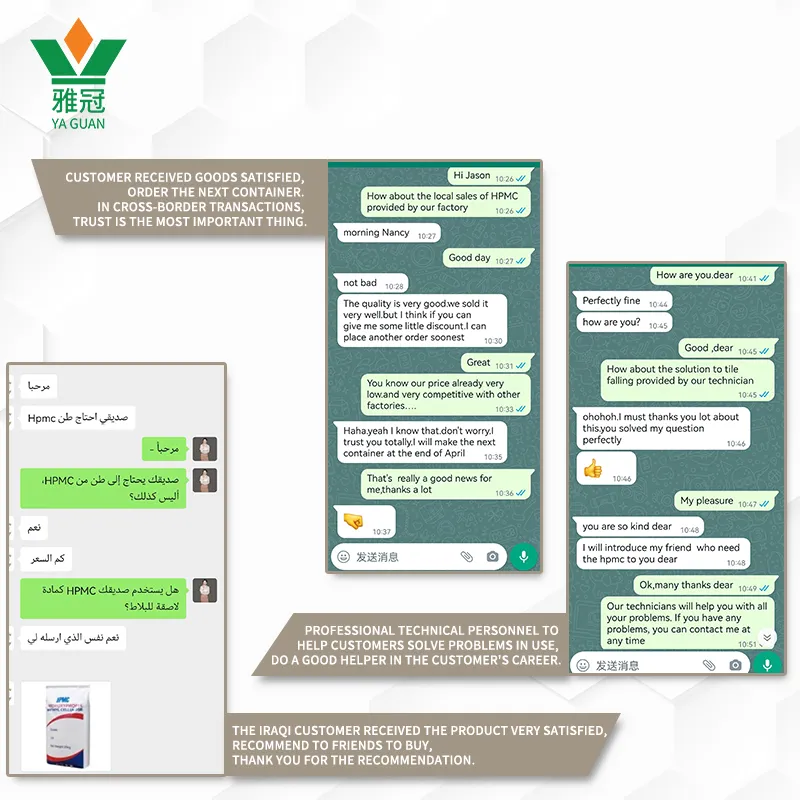

Our Partners

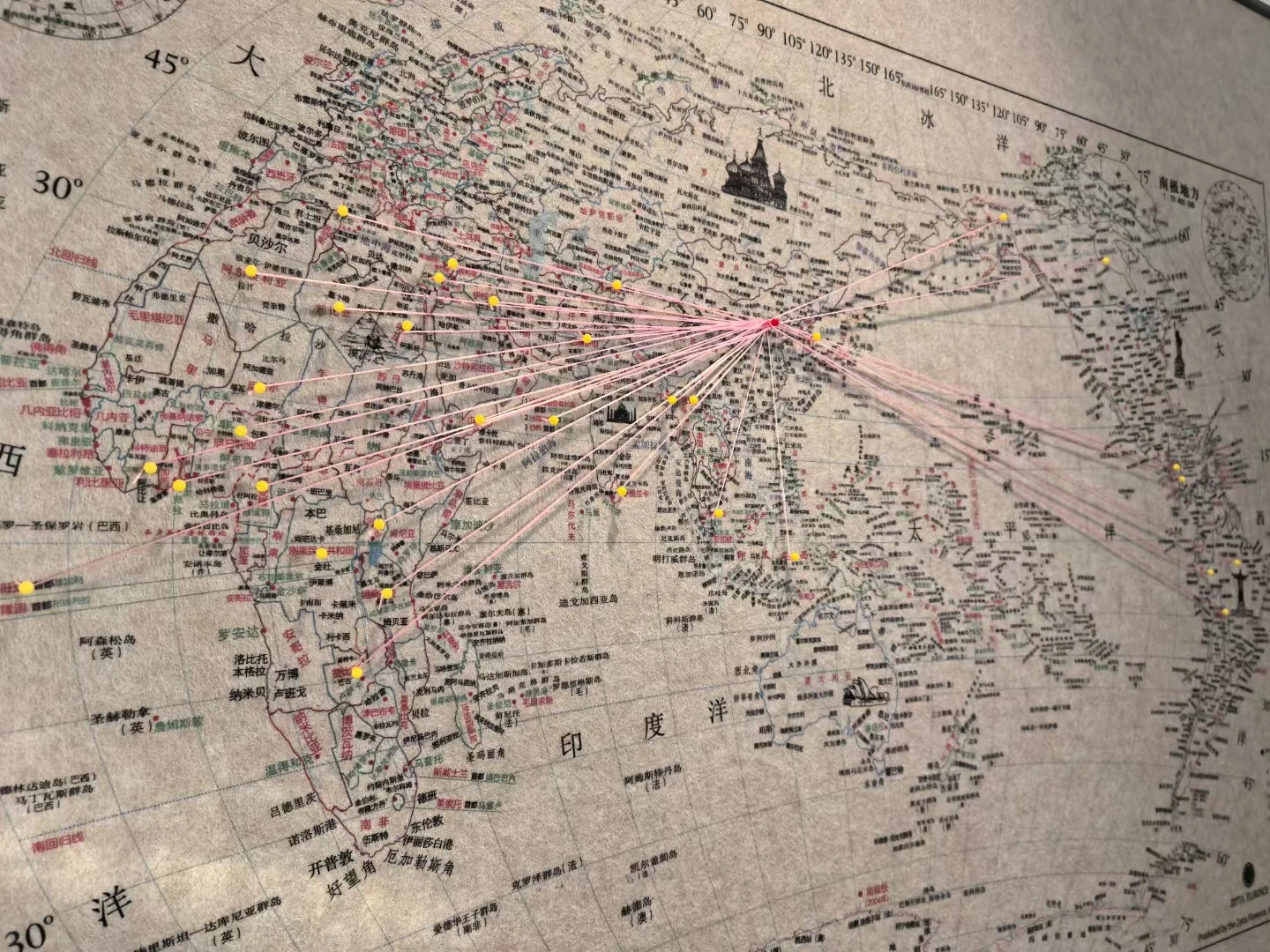

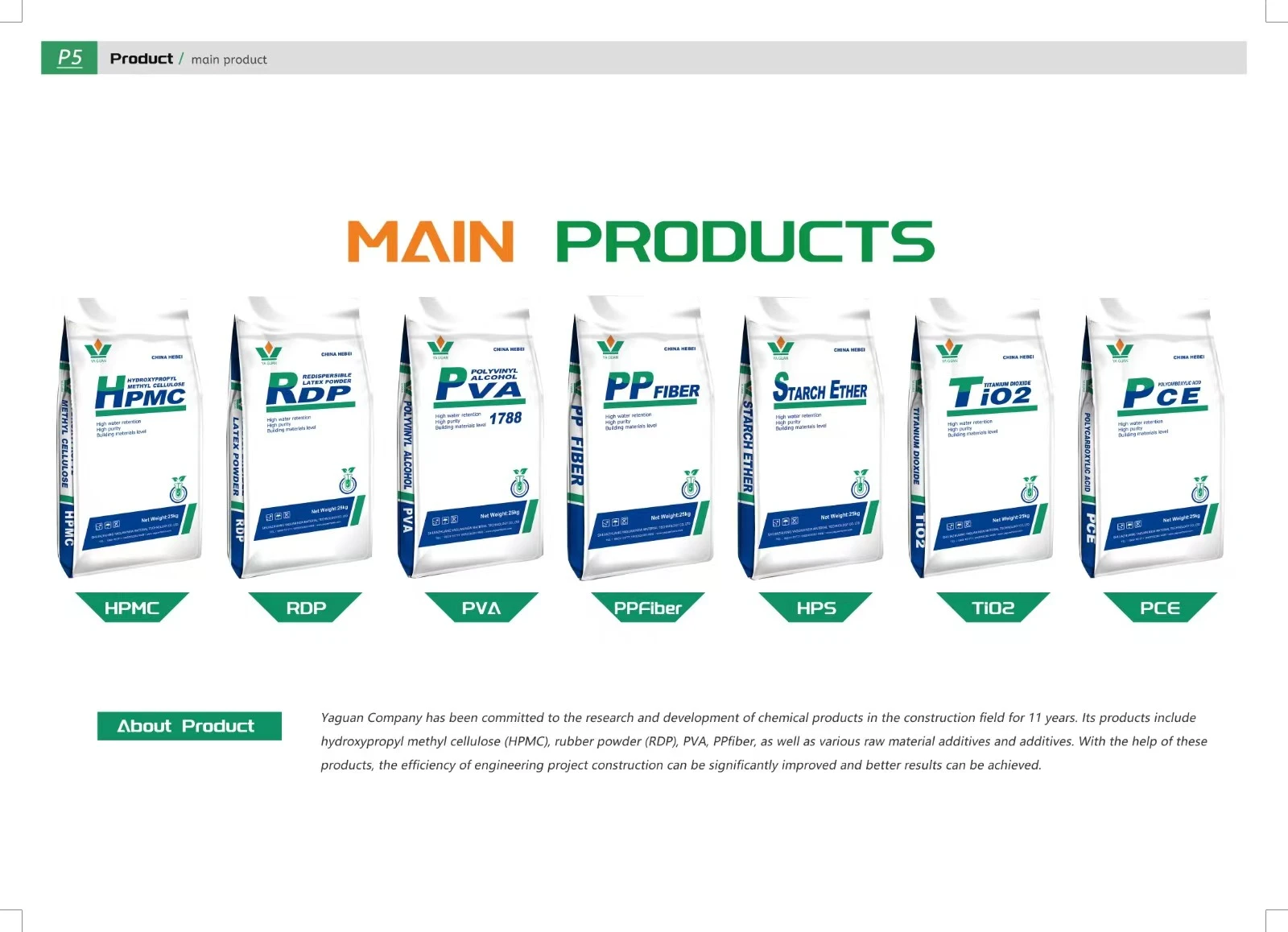

Shijiazhuang Yaguan New Material Technology Co., Ltd. is een industriële en handelsintegrerende onderneming met een grote expertise in onderzoek, ontwikkeling, productie, verkoop en service van vezeletherproducten.