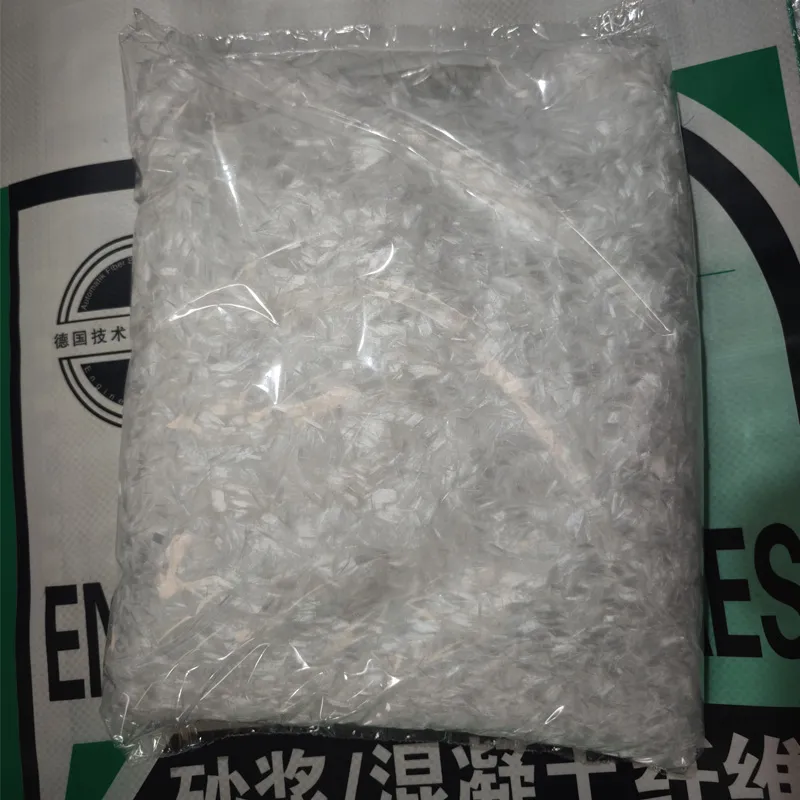

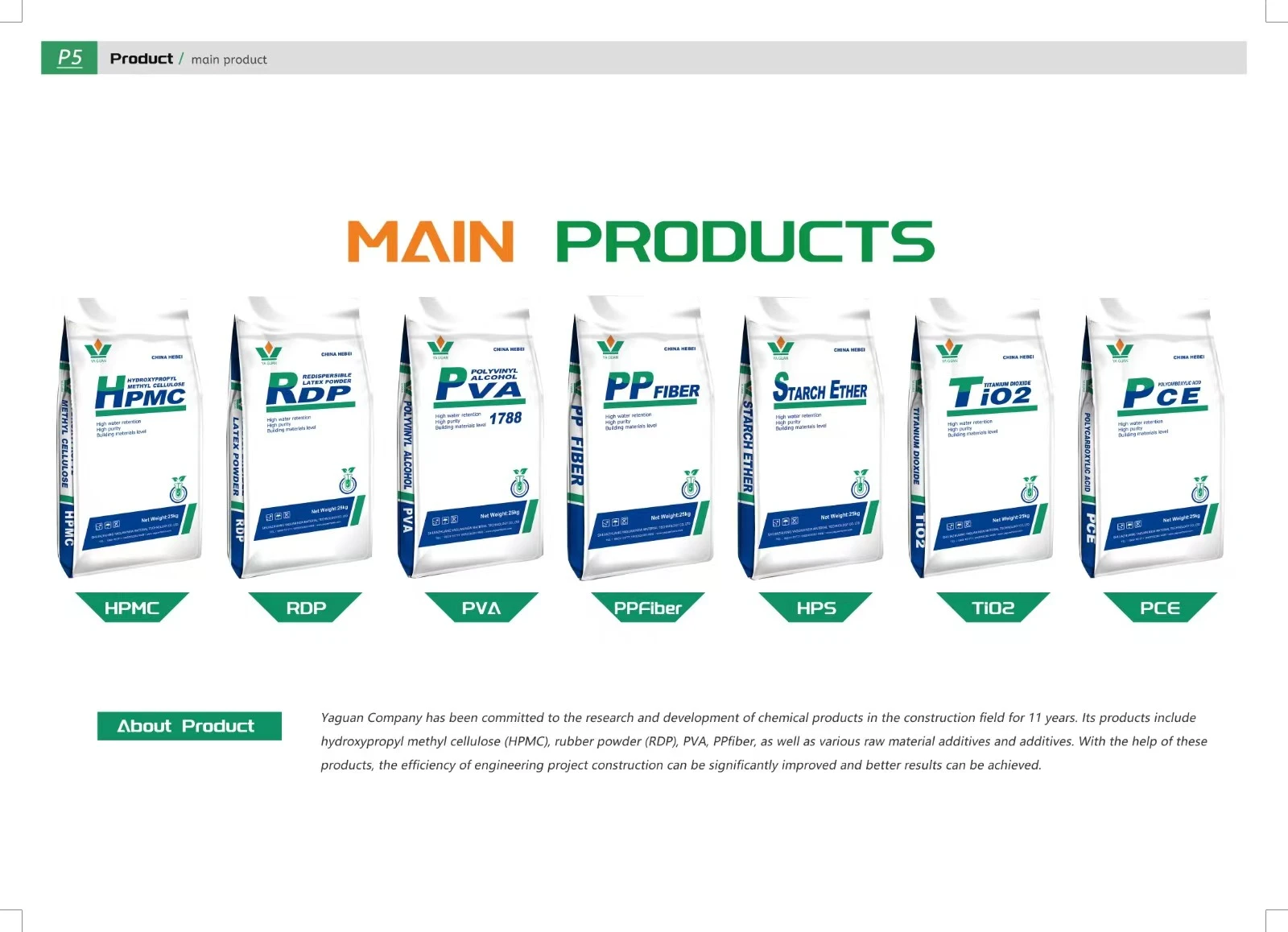

YAGUANPolypropylene Fiber,also known as anti-crackingfiber,PPfiber,or concrete fiber,is a high-strength bundled monofilament fiber made of polypropylene.The addition of our polypropylene fiber products to mortar or concrete can effectively control the micro-cracks of concretes or mortars caused by plastic shrink- age,dry shrinkage,temperature changes,and other factors,etc.At the same time,it can also prevent and inhib- itthe formation and development of cracks,thereby significantly improving the penetration resistance,impact resistance,and earthquake resistance of concretes.

◎ Easy to be dispersed in mortar or concrete and no agglomeration,it can guarantee the property of crack resistance effectively

◎ Easy to be used:No need to change the proportion of mortar,just put the fibers into the mortar mixture and stir fora moment after adding water

◎ Easy to plaster:As the great number of thin fibers spread into mortar evenly,the plastering is much easily and this can improve the binding strength between surface and base

◎ Itwith stable chemicalproperty,strong acid&alkali resistance,and can be used in any engineering projects

Product Specifications

|

INDEX NAME |

UNIT |

STANDARD SPECIFICATIONS |

|

Appearance |

- |

White,Bundled Mono Filament |

|

Tensile Strength |

(Mpa) |

≥450 |

|

Fiber dimension/Length |

(MM) |

3mm,6mm,9mm,12mm,18mm or customized |

|

Moisture Content |

(%) |

≤0.41 |

|

Density |

(G/CM³) |

0.91±0.02 |

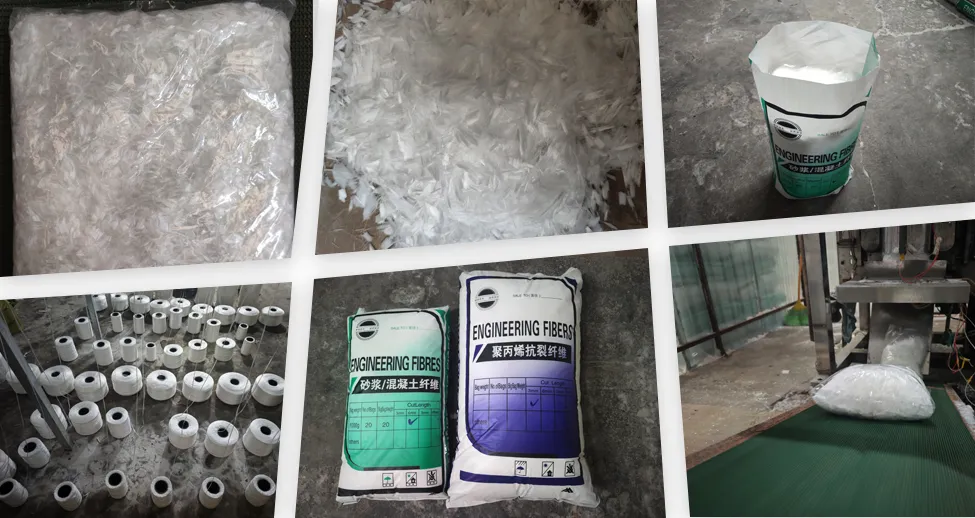

Product Package

1.Net Weight 25kg/bag,paper plastic composite bag lined with PE film bag. 2.Blank bags or OEM bags are available.

Polypropylene Fiber has the advantages of industrial application

Polypropylene Fiber has excellent chemical corrosion resistance, low water absorption, high strength and good dispersion, which makes it widely used in many industries such as construction, geoengineering, filtration materials, textile, automobile and so on. Especially when used as reinforcement fiber in concrete and mortar, it can effectively inhibit the generation of micro-cracks and improve the crack resistance, impact resistance and durability. Its lightweight, high-strength characteristics can significantly improve the overall toughness and fatigue resistance of concrete, especially in tunnels, roads, airport runways and other infrastructure projects.

In geotechnical engineering, polypropylene fiber is used to strengthen soil, control landslide and foundation stability, because of its acid and alkali resistance, aging resistance and other characteristics, can work steadily for a long time without being degraded. In the field of filtration materials, its good chemical stability and fiber structure make it a high-quality liquid and gas filtration material. In the textile industry, non-woven fabrics, carpets and industrial fabrics made of polypropylene fiber have the characteristics of light weight, wear-resistant, dry and breathable, and are widely used in medical, agricultural, packaging and other fields.

Polypropylene Fiber has the advantages of low cost, easy processing, environmental protection and non-toxic. It is one of the most cost-effective and flexible functional fiber materials in the industrial and civil fields. Its wide adaptability and excellent performance make it continue to show competitiveness in modern engineering and new materials industry.

Shipping Packaging

If you have any camping barbeque equipment inquiry, please feel free to contact us.