Introduction to Hydroxypropyl Methyl Cellulose (HPMC) and Industry Trends

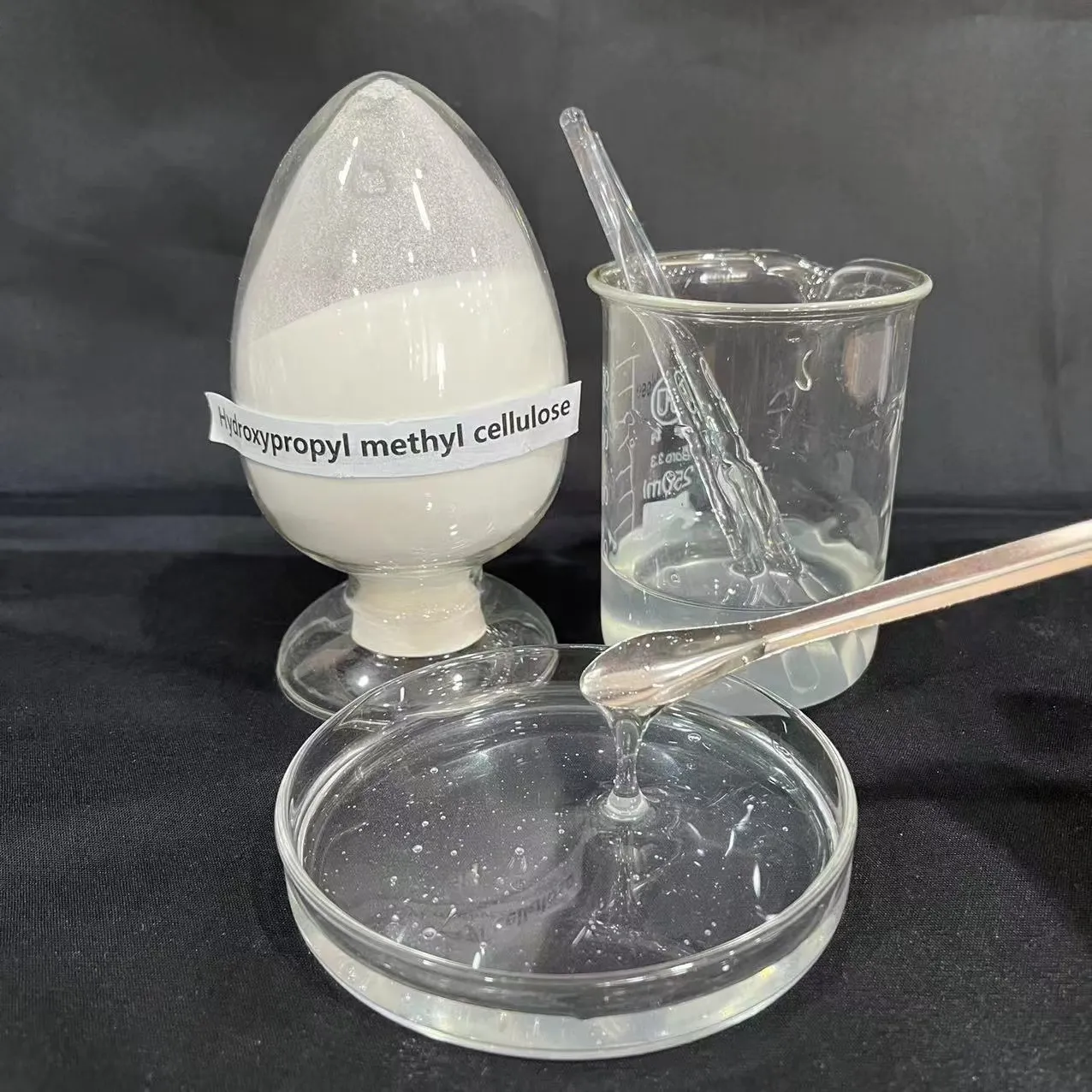

In the realm of advanced material science, Hydroxypropyl Methyl Cellulose (HPMC) stands out as a versatile, non-ionic cellulose ether with widespread applications across numerous industrial sectors. Derived from natural cellulose through a series of chemical reactions, HPMC is celebrated for its exceptional thickening, binding, film-forming, water retention, and suspension capabilities. Its unique properties make it an indispensable component in modern formulations, contributing significantly to product performance and efficacy.

The global market for HPMC is experiencing robust growth, primarily driven by expanding demands in the construction, pharmaceutical, food, and personal care industries. In construction, HPMC is crucial for enhancing the workability, adhesion, and water retention of cement-based products like tile adhesives, renders, and self-leveling compounds. The pharmaceutical sector leverages HPMC for its inertness and ability to function as a binder, disintegrant, controlled-release agent, and film-former for tablet coatings. Food-grade HPMC serves as a thickener, emulsifier, and stabilizer, improving texture and shelf-life, while in personal care, it acts as a rheology modifier and foam enhancer in cosmetics and detergents.

Industry trends indicate a sustained upward trajectory, fueled by technological advancements in HPMC manufacturing, increasing demand for eco-friendly and sustainable additives, and the continuous development of novel applications. The emphasis on high-performance building materials, stringent quality standards in pharmaceuticals, and the rising consumer preference for natural ingredient-derived products further underscore HPMC's pivotal role. Manufacturers are focusing on developing specialized HPMC grades with tailored viscosity profiles, substitution degrees, and surface treatments to meet increasingly complex application requirements, ensuring optimal performance and cost-effectiveness for B2B partners.

Hydroxypropyl Methyl Cellulose (HPMC) Manufacturing Process Flow

The production of Hydroxypropyl Methyl Cellulose (HPMC) is a sophisticated chemical synthesis process, beginning with high-purity refined cellulose as the primary raw material. The meticulous control at each stage ensures the final product's quality, consistency, and performance characteristics tailored for specific industrial applications.

Detailed Process Steps:

- Raw Material Preparation: High-purity wood pulp or cotton linter cellulose is selected as the base material. This natural polymer is first shredded and often dried to achieve a uniform moisture content, critical for subsequent reactions.

- Alkalization: The cellulose is treated with a concentrated caustic soda (NaOH) solution. This process activates the hydroxyl groups in the cellulose, converting them into highly reactive alkali cellulose. The quality of this activation step directly impacts the efficiency of the etherification.

- Etherification: The alkali cellulose is reacted with methyl chloride (CH₃Cl) and propylene oxide (CH₂OCHCH₃) in a precisely controlled, pressurized reactor. The methyl chloride introduces methyl groups, and propylene oxide introduces hydroxypropyl groups onto the cellulose backbone, forming Hydroxypropyl Methyl Cellulose (HPMC). The ratio and reaction conditions of these etherifying agents determine the degree of substitution (DS) and molar substitution (MS), which are crucial for the final product's properties like viscosity, thermal gelation, and water solubility.

- Neutralization: After etherification, the reaction mixture is neutralized with an acid (e.g., hydrochloric acid) to achieve a desired pH, typically around 6.0-7.0, to ensure product stability and safety.

- Washing & Purification: The crude HPMC is then thoroughly washed with hot water to remove residual salts (primarily NaCl) and unreacted byproducts. This purification step is critical to achieving high purity and low ash content, especially for pharmaceutical and food-grade HPMC. Advanced washing techniques, often involving counter-current washing, ensure maximum efficiency.

- Drying & Grinding: The purified HPMC is dried to a specific moisture content using advanced dryers (e.g., flash dryers or fluidized bed dryers). The dried material is then pulverized and ground to the desired particle size using specialized milling equipment. Particle size distribution is vital for solubility and dissolution rates.

- Sieving & Packaging: Finally, the powdered HPMC is sieved to ensure uniform particle size and remove any agglomerates. The finished product is then packaged in multi-ply paper bags or jumbo bags, often with an inner polyethylene liner, to protect against moisture and contamination.

Quality Control and Testing Standards:

Throughout the entire manufacturing process, stringent quality control measures are implemented. Key parameters such as viscosity, degree of substitution (DS), molar substitution (MS), pH, moisture content, heavy metals, and microbiological purity are rigorously tested. Products conform to international standards like ISO 9001 for quality management, and specific grades adhere to pharmacopoeia standards (USP, EP, JP) for pharmaceuticals or food additive regulations (FDA, EU). This ensures superior product consistency, reliability, and safety for demanding B2B applications. The service life of HPMC, when stored correctly, typically extends for 2-3 years without significant degradation of properties.

Technical Specifications and Properties of Hydroxypropyl Methyl Cellulose (HPMC)

Hydroxypropyl Methyl Cellulose (HPMC) is a complex polymer whose functional properties are dictated by its precise chemical structure and physical characteristics. Understanding these technical specifications is paramount for engineers and formulators to select the optimal grade for their specific application. The key parameters include the degree of substitution (DS), molar substitution (MS), viscosity, particle size, and thermal gelation temperature.

Structural and Physico-chemical Parameters:

- Degree of Substitution (DS): This refers to the average number of hydroxyl groups per anhydroglucose unit (AGU) that have been replaced by methoxy groups. For cellulose derivatives, the maximum theoretical DS is 3. A higher DS typically implies increased hydrophobicity.

- Molar Substitution (MS): This indicates the average number of moles of hydroxypropyl groups attached to each AGU. Unlike DS, MS can exceed 3 because the reaction can occur on the hydroxyl groups of the introduced hydroxypropyl substituents themselves, leading to longer side chains. Both DS and MS significantly influence solubility, thermal gelation, and surface activity.

- Viscosity: One of the most critical properties, viscosity is measured in solution (typically 2% in water at 20°C) and expressed in mPa·s (centipoise). HPMC is available in a vast range of viscosities, from low (e.g., 5 mPa·s) to very high (e.g., 200,000 mPa·s), enabling its use as a thickener, binder, or film-former across diverse applications. Viscosity is largely controlled by the degree of polymerization of the cellulose backbone.

- Thermal Gelation Temperature: HPMC solutions exhibit unique thermoreversible gelation properties. When heated above a certain temperature (the gelation temperature), the solution forms a gel, and upon cooling, it reverts to a liquid state. This temperature is influenced by the MS and DS values, as well as the concentration of HPMC in solution, making it valuable for applications requiring temperature-triggered thickening or structuring.

- Particle Size: The particle size distribution of powdered HPMC affects its dissolution rate and dispersibility. Fine powders (e.g., 80-120 mesh) dissolve faster but can be more prone to lumping, while coarser particles may require longer hydration times. Surface-treated HPMC grades are available for improved dispersion in aqueous systems.

- pH Stability: HPMC maintains stability and functionality across a broad pH range (typically 3-11), making it suitable for use in diverse chemical environments.

Typical Product Specification Table:

Below is a representative table outlining specifications for various grades of Hydroxypropyl Methyl Cellulose (HPMC), demonstrating how different properties are tailored for specific industrial requirements.

| Parameter | Unit | Grade A (Low Viscosity) | Grade B (Medium Viscosity) | Grade C (High Viscosity) | Grade D (Pharma Grade) |

|---|---|---|---|---|---|

| Viscosity (2% solution, 20°C) | mPa·s | 50 - 200 | 4,000 - 15,000 | 75,000 - 100,000 | 100 - 1,000 |

| Methoxy Content | % | 28.0 - 30.0 | 27.0 - 29.0 | 26.0 - 28.0 | 28.0 - 30.0 |

| Hydroxypropoxy Content | % | 7.0 - 12.0 | 4.0 - 7.5 | 4.0 - 7.0 | 7.0 - 12.0 |

| Gelation Temperature | °C (2% solution) | 70 - 90 | 60 - 75 | 50 - 65 | 75 - 90 |

| Вміст вологи | % | ≤ 5.0 | ≤ 5.0 | ≤ 5.0 | ≤ 5.0 |

| Ash Content | % | ≤ 1.5 | ≤ 1.5 | ≤ 1.5 | ≤ 0.5 (USP/EP) |

| Particle Size (80 Mesh) | % retained | ≤ 0.5 | ≤ 0.5 | ≤ 0.5 | ≤ 0.5 |

These detailed specifications allow B2B purchasers to precisely match HPMC grades to their manufacturing processes, ensuring optimal performance for their end products, whether it's for critical pharmaceutical applications or high-performance construction materials.

Key Application Scenarios and Technical Advantages of Hydroxypropyl Methyl Cellulose (HPMC)

The multifaceted properties of Hydroxypropyl Methyl Cellulose (HPMC) enable its use across a diverse range of industries, delivering critical performance enhancements in each. Its non-ionic nature, excellent water solubility, and film-forming capabilities are particularly advantageous.

Construction Industry:

- Tile Adhesives and Mortars: HPMC significantly improves water retention, extending the open time and adjustability of ceramic tile adhesives, especially in hot and dry climates. It enhances adhesion strength, sag resistance, and workability, leading to more efficient and durable installations. This translates to energy saving during application due to reduced rework and improved bond.

- Renders and Plasters: In cement and gypsum-based renders, HPMC provides excellent thixotropy, preventing sagging on vertical surfaces while ensuring smooth application. It also increases the bond strength between the render and the substrate, and minimizes cracking by controlling the hydration process.

- Self-Leveling Compounds: HPMC imparts optimal flow properties and anti-segregation characteristics, ensuring a smooth, uniform, and crack-free surface. It aids in achieving high compressive strength and abrasion resistance.

- External Thermal Insulation Composite Systems (ETICS): HPMC enhances the adhesion of insulation boards to the substrate and improves the flexibility and crack resistance of reinforcing mortars, contributing to the system's long-term durability and energy efficiency.

Pharmaceutical Industry:

- Tablet Binders and Excipients: As a non-toxic, inert excipient, HPMC acts as an effective binder in tablet formulations, improving tablet hardness and reducing friability.

- Controlled-Release Matrices: High-viscosity HPMC grades are extensively used to formulate hydrophilic matrix tablets that provide sustained or extended drug release, essential for maintaining therapeutic drug levels over time.

- Film Coatings: HPMC is a primary component in aqueous film-coating systems for tablets and capsules, offering excellent film-forming properties, high tensile strength, and good adhesion, protecting the active pharmaceutical ingredient (API) and improving swallowability.

- Topical Formulations: In ophthalmic solutions and topical gels, HPMC serves as a thickening agent and lubricant, enhancing viscosity and prolonging contact time with the application site.

Food Industry:

- Thickener and Stabilizer: HPMC is used in sauces, dressings, and dairy alternatives to improve texture, mouthfeel, and stability. Its thermal gelation property can be exploited to create specific textures in baked goods and processed foods.

- Emulsifier and Foam Stabilizer: It helps in stabilizing emulsions and foams in products like whipped toppings and ice cream.

Personal Care and Cosmetics:

- Thickener and Emulsifier: In shampoos, conditioners, lotions, and creams, HPMC provides rheology modification, improves product texture, and enhances stability.

- Film Former: Used in styling gels and makeup, it helps create a protective or setting film.

Technical Advantages and Performance Benchmarking of HPMC

The selection of an appropriate cellulose ether for industrial applications is a critical decision, directly impacting product performance, cost-efficiency, and processing ease. Hydroxypropyl Methyl Cellulose (HPMC) often emerges as the superior choice due to a distinct set of technical advantages when compared to other cellulose derivatives such as Methyl Cellulose (MC) or Carboxymethyl Cellulose (CMC).

Key Advantages of HPMC:

- Enhanced Water Retention: HPMC excels in retaining water, a crucial property in cementitious materials where it prevents premature drying, ensuring full hydration of cement and improved bond strength. In pharmaceutical applications, this property can be exploited for controlled drug release.

- Superior Thickening Efficiency: Depending on the grade, HPMC can provide significant viscosity at low concentrations, making it a cost-effective thickener. Its pseudoplastic rheology (shear-thinning behavior) is highly desirable, offering easy application under shear and structural recovery at rest.

- Broad pH Stability: Unlike ionic cellulose ethers like CMC, HPMC maintains its viscosity and stability over a wide pH range (typically 3-11), making it suitable for more diverse formulations without risk of precipitation or performance degradation.

- Excellent Film Formation: HPMC forms strong, flexible, and transparent films, which is invaluable in tablet coatings, protective coatings for fruits/vegetables, and personal care products. These films offer good barrier properties against moisture and oxygen.

- Thermo-Reversible Gelation: The ability of HPMC solutions to gel upon heating and liquefy upon cooling is a unique feature. This property can be engineered for specific applications requiring heat-set gelling or controlled release.

- Corrosion Resistance & Energy Saving: In industrial coatings and protective layers, the film-forming capabilities of HPMC can contribute to the creation of protective barriers. In construction, improved workability and reduced material waste directly lead to energy savings during application and longer service life for structures.

Product Comparison Table: HPMC vs. Other Cellulose Ethers

This table benchmarks key performance indicators, aiding in the informed selection of the most suitable cellulose ether for specific B2B needs.

| Feature / Property | HPMC | Methyl Cellulose (MC) | Carboxymethyl Cellulose (CMC) | Hydroxyethyl Cellulose (HEC) |

|---|---|---|---|---|

| Water Retention | Excellent | Very Good | Good | Good |

| Thickening Efficiency | High | High | Moderate to High | Moderate to High |

| Thermal Gelation | Yes (Thermally Reversible) | Yes (Thermally Reversible) | No | No |

| pH Stability (Functional Range) | Wide (3-11) | Wide (3-11) | Limited (6-9, ionic) | Wide (3-10, non-ionic) |

| Ionic Nature | Non-ionic | Non-ionic | Anionic | Non-ionic |

| Film Strength & Flexibility | Excellent | Good | Moderate | Good |

| Dispersibility | Good (Surface-treated grades available for improved cold-water dispersion) | Good (Surface-treated grades available) | Excellent (Readily soluble) | Excellent (Readily soluble) |

Vendor Comparison and Customized Solutions for Hydroxypropyl Methyl Cellulose (HPMC)

Selecting the right supplier for Hydroxypropyl Methyl Cellulose (HPMC) is as crucial as understanding its technical properties. A reliable vendor not only provides a high-quality product but also offers robust technical support and the flexibility for customized solutions to meet precise B2B requirements.

Key Factors for Vendor Comparison:

- Product Quality and Consistency: The ability of a vendor to consistently deliver HPMC with uniform viscosity, substitution levels, and particle size is paramount. Inconsistencies can lead to significant variations in end-product performance, rework, and increased costs. Reputable vendors will have robust ISO 9001 certified quality management systems and detailed batch analysis reports.

- Technical Support and Expertise: A strong vendor should offer deep technical knowledge and support, assisting clients in selecting the appropriate HPMC grade, troubleshooting formulation challenges, and optimizing application processes. This includes providing comprehensive data sheets, safety information, and expert consultation.

- Certifications and Regulatory Compliance: For specialized applications (e.g., pharmaceutical, food), adherence to specific regulatory standards (USP, EP, JP, FDA, Halal, Kosher, REACH) is non-negotiable. Verify that the vendor possesses all necessary certifications for their HPMC products.

- Supply Chain Reliability and Lead Times: Consistent supply, efficient logistics, and predictable lead times are critical for maintaining continuous production. Evaluate a vendor's production capacity, inventory management, and global distribution network.

- Research and Development Capabilities: Vendors with strong R&D capabilities are often at the forefront of innovation, developing new HPMC grades and specialized solutions that can provide a competitive edge.

Customized Solutions for HPMC:

While standard grades of Hydroxypropyl Methyl Cellulose (HPMC) fulfill many industrial needs, specific applications often benefit significantly from tailored solutions. A responsive and capable vendor can customize HPMC to optimize performance for unique formulations and processing conditions. Customization options typically include:

- Specific Viscosity Ranges: Adjusting the polymerization degree allows for very precise viscosity control, critical for rheology modification in everything from thick paints to thin tablet coatings.

- Optimized Substitution Levels (DS/MS): Altering the ratio of methyl and hydroxypropyl groups can fine-tune properties such as water solubility, thermal gelation temperature, and organic solubility. This is particularly important for achieving specific dissolution profiles in pharmaceutical matrices or desired open times in construction mortars.

- Particle Size Distribution: Custom grinding and sieving can produce HPMC with specific particle sizes, influencing dissolution rate, dispersibility, and anti-lumping characteristics in powder blends. Finer particles may be preferred for rapid hydration, while coarser particles can offer extended open times.

- Surface Treatment: Surface-treated (e.g., glyoxal-treated) HPMC grades prevent instant dissolution and agglomeration in cold water, allowing for better dispersion before full hydration and thickening occurs. This is vital for ease of mixing in many industrial processes.

- Purity and Impurity Profile: For sensitive applications like injectables or food, custom solutions can involve enhanced purification steps to meet ultra-low limits for heavy metals, residual solvents, or microbial load.

Engaging with a vendor that offers strong customization capabilities ensures that the Hydroxypropyl Methyl Cellulose (HPMC) integrates seamlessly into existing production lines and delivers maximum performance, optimizing both technical output and economic efficiency.

Application Case Studies & Customer Experience with HPMC

The practical benefits of Hydroxypropyl Methyl Cellulose (HPMC) are best demonstrated through real-world application case studies and direct customer feedback. These examples highlight how tailored HPMC solutions drive innovation and solve critical challenges across diverse industries. With decades of experience in the cellulose ether market, our solutions have consistently delivered exceptional results for a global clientele.

Case Study 1: Enhancing High-Performance Tile Adhesives in Arid Environments

A leading construction material manufacturer faced significant challenges in formulating tile adhesives for arid and hot regions. Rapid water evaporation from the adhesive bed led to premature drying, poor open time, reduced adhesion, and increased material waste. Their existing cellulose ether provided insufficient water retention under these harsh conditions.

- Solution Provided: Our technical team collaborated with the client to develop a customized high-viscosity HPMC grade with an optimized hydroxypropyl content, specifically engineered for superior water retention and extended open time. This particular Hydroxypropyl Methyl Cellulose (HPMC) was also surface-treated to ensure excellent dispersion in their dry-mix formulation.

- Results: The new HPMC formulation extended the adhesive's open time by 30-40 minutes in typical 35°C, 30% RH conditions, surpassing industry standards. This drastically improved workability, allowed for greater adjustment time for tiles, and significantly reduced premature skinning. The final adhesive achieved over 2.0 MPa adhesion strength after 28 days, far exceeding the client's previous performance benchmarks and dramatically reducing costly callbacks due to adhesion failures.

- Customer Feedback: "The tailored HPMC solution from [Company Name] transformed our tile adhesive line. We've seen a measurable improvement in product performance and customer satisfaction, allowing us to capture a larger share of the high-performance adhesive market in challenging climates. Their technical support was invaluable throughout the development process."

Case Study 2: Achieving Precision in Controlled-Release Pharmaceutical Formulations

A pharmaceutical company specializing in generic drugs needed to replicate the precise drug release profile of an innovator product for a once-daily extended-release tablet. Achieving the exact dissolution kinetics was critical for bioequivalence and regulatory approval. The challenge lay in finding an HPMC grade that could form a stable hydrophilic matrix with consistent swelling and erosion characteristics.

- Solution Provided: We supplied a specific medium-viscosity Hydroxypropyl Methyl Cellulose (HPMC), manufactured under strict cGMP conditions, with a very tight specification for both viscosity and substitution levels (methoxy and hydroxypropoxy content). Our quality assurance data, including comprehensive batch records and stability data, assured the client of its suitability. Through iterative testing and R&D collaboration, the precise blend of HPMC grades was fine-tuned.

- Results: The optimized HPMC matrix successfully mimicked the innovator product's 24-hour drug release profile, exhibiting excellent consistency batch-to-batch. This enabled the client to achieve bioequivalence, secure regulatory approval, and launch their generic product ahead of schedule. The HPMC's uniform particle size also ensured smooth tablet compression and minimal dust generation.

- Client Testimonial: "The reliability and quality of HPMC from [Company Name] were instrumental in our successful product launch. Their commitment to cGMP standards and ability to provide highly consistent material gave us the confidence needed for such a critical formulation."

Authoritativeness and Trustworthiness: Our Commitment to Quality and Service

Our dedication to delivering superior Hydroxypropyl Methyl Cellulose (HPMC) solutions is underpinned by a steadfast commitment to authoritativeness and trustworthiness. We understand that for B2B partners, confidence in product quality, compliance, and support is paramount.

Certifications and Quality Assurance:

We operate under a comprehensive quality management system that ensures every batch of HPMC meets stringent internal and international standards. Our manufacturing facilities are ISO 9001 certified, guaranteeing consistent processes and continuous improvement. For pharmaceutical and food-grade HPMC, we adhere to Good Manufacturing Practices (GMP) and hold certifications such as USP (United States Pharmacopeia), EP (European Pharmacopoeia), JP (Japanese Pharmacopoeia), FDA registration, Halal, Kosher, and REACH compliance. These certifications are a testament to our rigorous quality control, from raw material sourcing to final product packaging. Our long-standing relationships with global partner clients, spanning over two decades, are a direct reflection of our consistent product quality and reliable service.

Lead Time & Fulfillment Details:

We recognize the importance of timely delivery in maintaining our clients' production schedules. Our optimized supply chain and robust production capacity enable us to offer competitive lead times. Standard HPMC grades typically have a lead time of 10-15 business days for ex-works orders, with expedited options available for urgent requirements. For customized HPMC solutions, lead times are discussed and confirmed at the time of order placement, accounting for specific production adjustments. We provide detailed order tracking and work with reputable logistics partners to ensure secure and efficient global delivery.

Warranty Commitments:

All our Hydroxypropyl Methyl Cellulose (HPMC) products come with a standard warranty, guaranteeing that they conform to the agreed-upon technical specifications and are free from manufacturing defects. Our warranty period typically covers 12 to 24 months from the date of manufacture, provided the product is stored under recommended conditions. In the rare event of a quality concern, our dedicated technical and customer service teams are committed to prompt investigation and resolution.

Comprehensive Customer Support:

Our commitment extends beyond product delivery. We provide comprehensive after-sales support, including:

- Technical Consultation: Our team of experienced chemists and application engineers is available to offer expert advice on product selection, formulation optimization, and process troubleshooting.

- Sample Provision: We provide product samples for testing and evaluation to ensure suitability before bulk orders.

- Documentation Support: Full access to Certificates of Analysis (CoA), Material Safety Data Sheets (MSDS), technical data sheets, and regulatory compliance documents.

- Responsive Communication: Dedicated account managers and customer service representatives ensure that inquiries are addressed promptly and effectively.

Frequently Asked Questions (FAQ) about Hydroxypropyl Methyl Cellulose (HPMC)

Q1: What is the primary difference between HPMC and CMC?

A1: Hydroxypropyl Methyl Cellulose (HPMC) is a non-ionic cellulose ether, meaning it does not carry an electrical charge in solution. This makes it less sensitive to pH changes and the presence of salts. Carboxymethyl Cellulose (CMC), on the other hand, is an anionic cellulose ether, carrying a negative charge. CMC's viscosity and solubility can be significantly affected by pH variations and high salt concentrations. HPMC also exhibits thermal gelation, a property not found in CMC.

Q2: How should HPMC be stored to maintain its quality?

A2: HPMC should be stored in its original, unopened packaging in a cool, dry place, away from direct sunlight and heat sources. It is hygroscopic, meaning it absorbs moisture from the air, which can lead to caking and reduced performance. Therefore, a humidity-controlled environment is ideal. Properly stored HPMC typically maintains its properties for 24-36 months.

Q3: Can HPMC be used in both hot and cold water applications?

A3: Yes, HPMC is cold-water soluble. Many grades, especially those surface-treated (e.g., glyoxal-treated), disperse well in cold water to prevent lumping before hydration and viscosity development. While HPMC dissolves in cold water, its thermal gelation property means that its aqueous solutions will form a gel when heated above a specific temperature, making it unsuitable for hot-fill applications where a liquid state is required. However, this property is desirable in applications requiring heat-set gelling.

Q4: What is the role of HPMC in controlled-release drug delivery?

A4: In controlled-release drug delivery, HPMC forms a hydrophilic matrix when it comes into contact with aqueous media. This matrix swells and forms a viscous gel layer around the tablet core. The drug then slowly diffuses through this gel layer or is released as the matrix erodes, providing a sustained release profile over an extended period. The viscosity and substitution type of the Hydroxypropyl Methyl Cellulose (HPMC) are critical in tuning the release rate.

Q5: How do I select the correct viscosity grade of HPMC for my application?

A5: The selection of HPMC viscosity depends heavily on the desired rheology and functionality in the final product. For high-performance construction mortars, a high viscosity (e.g., 75,000-100,000 mPa·s) is often chosen for excellent water retention and sag resistance. For film coatings in pharmaceuticals, lower viscosities (e.g., 50-100 mPa·s) are preferred for smooth, thin films. We recommend consulting our technical data sheets and engaging with our application specialists to determine the optimal viscosity and other parameters for your specific formulation.

Conclusion

Hydroxypropyl Methyl Cellulose (HPMC) stands as a cornerstone in modern industrial formulations, offering an unparalleled combination of versatility, performance, and stability. From enhancing the durability of construction materials and enabling advanced drug delivery systems to refining food textures and optimizing cosmetic formulations, HPMC's unique properties make it an indispensable additive. As industries continue to evolve, demanding more sustainable, efficient, and high-performance solutions, the role of HPMC is set to expand further, driven by ongoing research and development into specialized grades and novel applications. Our commitment to quality, technical expertise, and customized solutions ensures that our partners are equipped with the precise HPMC products needed to achieve their manufacturing excellence and market leadership.

References

- Rowe, R. C., Sheskey, P. J., & Quinn, M. E. (2009). Handbook of Pharmaceutical Excipients. Pharmaceutical Press.

- Klemm, D., Philipp, B., Heinze, T., Heinze, U., & Wagenknecht, W. (1998). Comprehensive Cellulose Chemistry: Fundamentals and Applications. Wiley-VCH.

- Bochek, A. M. (2007). Physical chemistry of cellulose and cellulose ethers. Russian Journal of Applied Chemistry, 80(6), 875-885.

- US Food and Drug Administration. (n.d.). Hydroxypropyl Methylcellulose (HPMC) in Food Applications.

- European Pharmacopoeia. (2020). Hydroxypropylmethylcellulose. EDQM.