In modern industrial chemistry, materials like polyvinyl alcohol for sale, cellulose ether hpmc, and hydroxypropyl methyl cellulose ether play pivotal roles across a wide range of applications. These chemical compounds are highly valued for their versatility, functionality, and performance-enhancing properties. Whether it's construction, pharmaceuticals, textiles, or adhesives, their influence extends to every corner of the global supply chain. With the chemical industry rapidly evolving toward eco-efficiency and high-performance formulations, understanding the unique benefits and applications of cellulose 2 hydroxyethyl ether and related cellulose derivatives becomes essential for informed decision-making.

Material Characteristics and Advantages

The foundation of any industrial material lies in its physical and chemical characteristics. Polyvinyl alcohol for sale is a synthetic polymer derived from polyvinyl acetate, known for its excellent film-forming, emulsifying, and adhesive properties. It is also water-soluble and biodegradable, making it highly desirable in industries moving toward sustainable practices. Its high tensile strength and flexibility enable superior performance in coatings, textiles, and packaging materials.

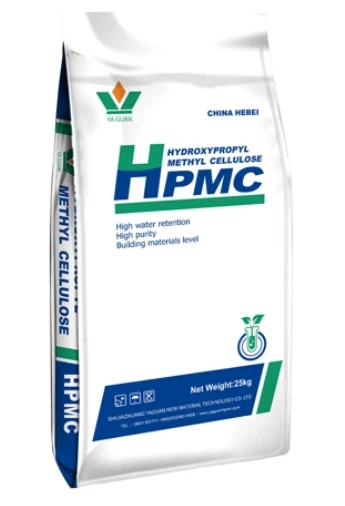

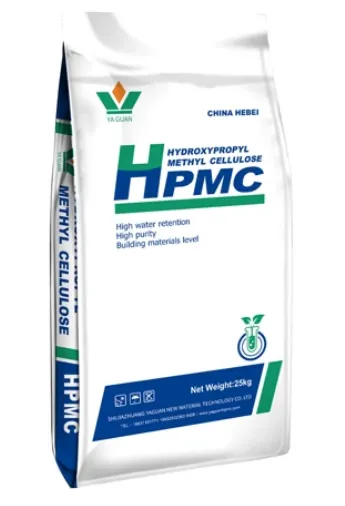

On the other hand, cellulose ether hpmc, a derivative of natural cellulose, is renowned for its thickening, stabilizing, and water retention properties. It is widely used in construction materials such as tile adhesives and plaster because it improves workability and prolongs open time. Likewise, hydroxypropyl methyl cellulose ether combines the advantages of both methyl and hydroxypropyl groups, offering better solubility and enhanced thermal stability. This makes it an indispensable ingredient in drug delivery systems, cosmetics, and even food-grade applications.

cellulose 2 hydroxyethyl ether adds another layer of functional flexibility. It exhibits excellent film-forming abilities, pH stability, and low toxicity, making it suitable for personal care products, emulsions, and paints. These characteristics allow manufacturers to customize product formulations based on viscosity, solubility, and temperature resistance—key performance indicators in competitive industrial sectors.

Applications Across Core Industries

The significance of these materials becomes clearer when we examine their widespread application. Polyvinyl alcohol for sale is commonly used in textile sizing agents, offering increased fabric strength and reduced fraying during weaving. Its emulsifying nature also makes it valuable in the production of polyvinyl butyral (PVB), used for laminated safety glass in automotive and architectural applications.

In construction, cellulose ether hpmc has revolutionized the performance of dry mix mortars and cement-based products. It improves adhesion, water retention, and consistency, allowing masons and contractors to deliver better results even under challenging climatic conditions. Its ease of handling and non-toxic profile also enhance worker safety on-site.

Hydroxypropyl methyl cellulose ether has become essential in pharmaceutical manufacturing, especially for controlled-release formulations. Its ability to form gels and films makes it ideal for tablet coatings and capsule production. In food applications, it serves as a gluten alternative, offering structure and moisture retention in gluten-free baked goods.

Meanwhile, cellulose 2 hydroxyethyl ether finds frequent use in personal care formulations, particularly in shampoos, lotions, and creams. It ensures smooth texture, consistent viscosity, and effective emulsification—all crucial factors in user satisfaction and brand perception. The compound is also useful in water-based paints and coatings, where it prevents sagging and enhances film strength during application.

Global Demand and Market Dynamics

As global industries prioritize sustainability and performance, the demand for advanced cellulose ethers and polyvinyl compounds continues to rise. Emerging markets in Southeast Asia, Africa, and Latin America are becoming key growth regions due to increased urbanization and infrastructure development. Governments in these areas are also promoting green building standards, further accelerating the adoption of materials like cellulose ether hpmc and hydroxypropyl methyl cellulose ether.

The pharmaceutical and personal care sectors, particularly in developed markets, are pushing for cleaner formulations with minimal environmental impact. This shift is creating a consistent demand for cellulose 2 hydroxyethyl ether, which offers a balance between function and sustainability. Meanwhile, the packaging industry’s interest in biodegradable materials is fueling investment in polyvinyl alcohol for sale, especially for single-use items that must comply with new regulatory norms.

Supply chain considerations also influence the material landscape. Companies are now evaluating suppliers based not only on cost but also on their sustainability credentials, manufacturing transparency, and product consistency. As a result, manufacturers with vertically integrated production systems and global certifications are better positioned to meet the evolving expectations of industrial clients.

Choosing the Right Supplier for Strategic Advantage

In a market saturated with options, selecting a reliable supplier is essential to ensure product integrity and long-term performance. Reputable manufacturers of cellulose ether and polyvinyl alcohol for sale often invest heavily in research and development to refine their chemical formulations and expand their application range. This innovation-driven approach helps businesses maintain a competitive edge in their respective industries.

When evaluating a supplier, it is important to assess their production capacity, quality control mechanisms, and technical support services. Suppliers offering customization capabilities for hydroxypropyl methyl cellulose ether or cellulose 2 hydroxyethyl ether can provide significant value by aligning products with specific application requirements. Additionally, global delivery networks and prompt customer service ensure operational continuity and reduce project delays.

Moreover, companies committed to ethical sourcing and sustainability practices offer additional reassurance. A transparent sourcing model, third-party certifications (e.g., ISO, FDA, REACH), and published sustainability reports signal reliability and accountability. For forward-thinking enterprises, aligning with such suppliers strengthens ESG compliance and enhances corporate reputation.

Cellulose ether FAQs

What is the difference between cellulose ether hpmc and other cellulose ethers?

Cellulose ether hpmc stands out for its exceptional water retention, thermal stability, and pH tolerance. Compared to other cellulose ethers, HPMC offers greater consistency in performance across a wide temperature range and is particularly suited for construction and pharmaceutical applications where viscosity and film-forming ability are critical.

How is polyvinyl alcohol for sale typically used in packaging?

Polyvinyl alcohol for sale is widely used in biodegradable and water-soluble packaging films, especially for single-use items. It forms strong, flexible films that are resistant to grease and oil, making it ideal for unit-dose detergent pods, medical pouches, and agricultural products. Its biodegradability also aligns with increasing global sustainability standards.

Is hydroxypropyl methyl cellulose ether safe for food and pharmaceutical applications?

Yes, hydroxypropyl methyl cellulose ether is considered safe for both food and pharmaceutical use. It is non-toxic, non-allergenic, and approved by regulatory agencies like the FDA and EFSA. In pharmaceuticals, it acts as a binder and controlled-release agent, while in food it is used as a stabilizer and thickening agent in various products.

Can cellulose 2 hydroxyethyl ether be used in high-pH systems?

Yes, cellulose 2 hydroxyethyl ether exhibits excellent stability across a wide pH range, including high-pH environments. This makes it suitable for alkaline formulations such as certain industrial cleaners, water-based paints, and construction grouts where maintaining consistent viscosity is essential.

What should be considered when choosing a cellulose ether supplier?

Key factors include product consistency, technical support, certification, and the ability to meet regulatory standards. It’s also important to consider the supplier’s reputation for R&D, which ensures they can deliver application-specific solutions. Global logistics capabilities and sustainable practices further contribute to long-term value.