Redispersible Polymer Powder (RDP) is a vital additive specially engineered for advanced dry mortar formulations in the construction chemicals industry. Derived mainly from ethylene-vinyl acetate (EVA), vinyl acetate-vinyl versatate (VeoVa), or acrylate, RDP enhances mortar flexibility, adhesion, resistance to water, and workability, making it a preferred choice across diverse sectors such as construction, waterproofing, tile adhesives, self-leveling compounds, and external thermal insulation systems (EIFS).

According to Mordor Intelligence, the global RDP market size exceeded $2.1 billion USD in 2023 and is expected to grow at a CAGR of 6.3% through 2028, fueled by infrastructure spending, green building standards, and the continuous evolution of high-performance mortars.

Advanced Redispersible Polymer Powder (RDP) is precisely formulated to strict international standards (ISO 9001, ASTM C605) to deliver optimal performance in challenging applications. Below is a detailed technical parameter comparison from leading manufacturer datasheets:

| Parameter | Specification | Test Standard | Typical Value |

|---|---|---|---|

| Appearance | White free-flowing powder | Visual | White powder, no agglomerate |

| Base Polymer | EVA / VINYL ACETATE-ETHYLENE | FTIR | EVA |

| Solid Content (%) | ≥98.0 | ISO 3251 | 99.0 |

| Bulk Density (g/L) | 400–600 | DIN EN ISO 60 | 480 |

| Particle Size (μm) | 80–130 | Laser Diffraction | 110 |

| MFFT (°C) | 0–5 | DSC | 4 |

| pH Value | 5.0–8.0 | DIN ISO 976 | 7 |

| Redispersibility (%) | ≥95 | In-House | 98 |

| Film-Forming Temperature (°C) | ≥0 | ISO 2115 | 2 |

| Recommended Dosage (%) | 0.5–3% by weight | Application Guide | 1.5% |

As demonstrated below, the global technological advancements in RDP contribute significantly to improved flexibility, bond strength, and durability. The following data visualizations employ ECharts for interactive exploration (please ensure JavaScript is enabled in your browser):

The manufacturing of Redispersible Polymer Powder (RDP) requires a combination of polymerization, advanced spray-drying, and strict quality inspection, ensuring consistent product quality and performance. The typical process includes:

- Polymerization: EVA / VaE base polymers are synthesized via emulsion polymerization.

- Stabilization & Emulsification: Additives and protective colloids (polyvinyl alcohol) incorporated.

- Spray Drying: The polymer emulsion is atomized into hot air chambers, rapidly forming dry, flowable powder particles.

- Sieving & Packaging: Powder is sieved for uniformity, metal-checked, and packed in multilayer paper bags with PE liners.

- Quality Inspection: In-house testing for solid content, film-forming ability, and redispersibility based on ISO/ASTM standards.

Visual guide:

- Material: EVA-based copolymers; meets RoHS and REACH directives.

- Core Processes: Polymerization, High-precision Spray Drying (CNC Atomizer), Inline Particle Analysis.

- Quality Control: Complies with ISO 9001:2015 and ANSI standards. Lot-based testing for redispersibility/film integrity.

- Service Lifetime: Shelf life ≥ 24 months in cool/dry storage.

- Suitable Industries: Construction, petrochemicals, metallurgy, wastewater, and more.

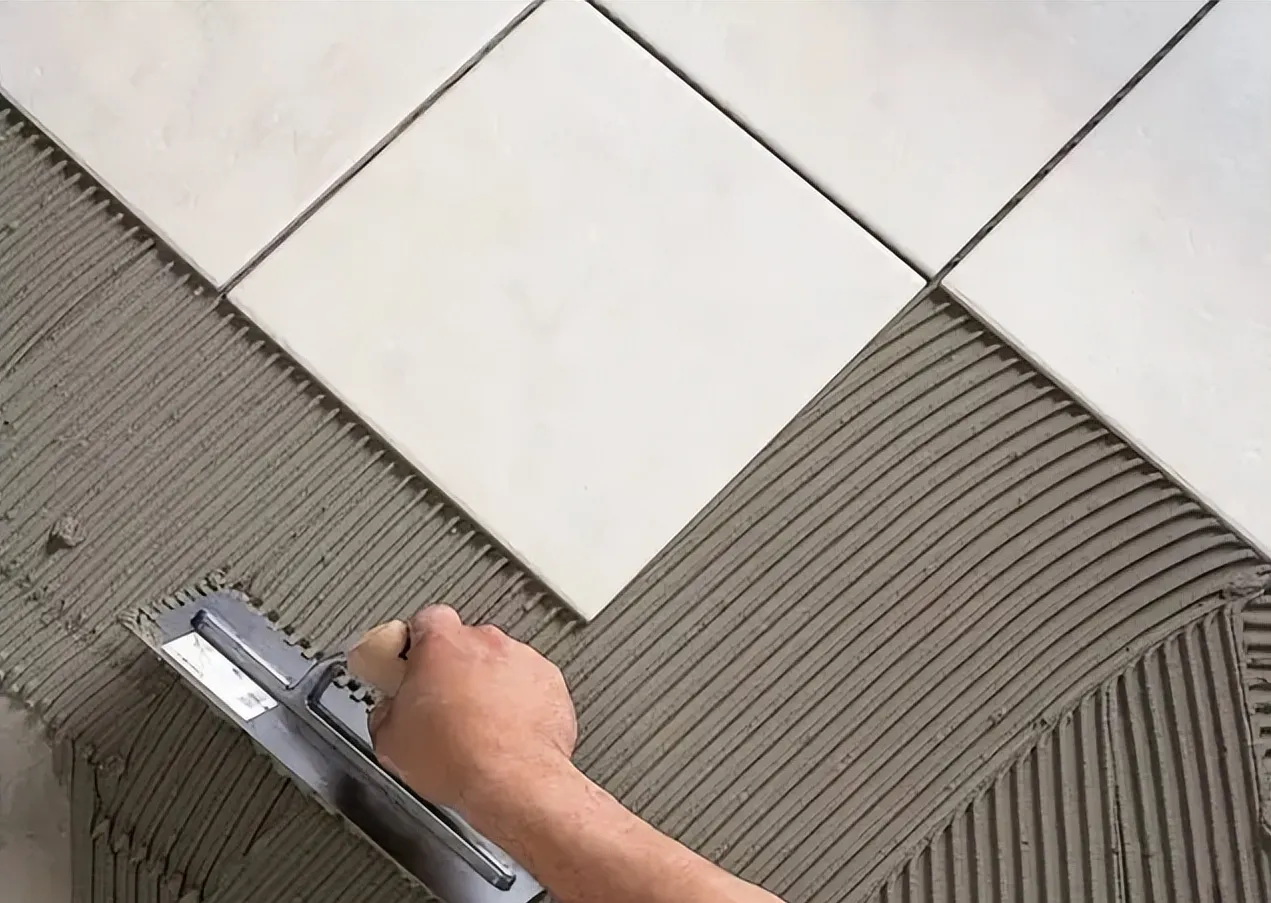

Redispersible Polymer Powder (RDP) is crucial for a wide array of construction solutions due to its improved bonding, cracking resistance, and workability. Below are exemplary application cases:

- 1. Tile Adhesives & Grouts: RDP enhances open time and adhesion strength. Used in Redispersible Polymer Powder (RDP)-modified mortars achieving ≥ 1.2 MPa (ISO 13007).

- 2. Exterior Insulation Finishing Systems (EIFS): Superior anti-cracking performance and thermal efficiency. Yaguan RDP formulated EIFS exhibit flexibility > 20% after 500 freeze-thaw cycles.

- 3. Self-Leveling Compounds: RDP ensures smooth flow, self-healing cracks, and optimal surface finish. Bond strength improves by 22% vs. unmodified mortars (see ECharts).

- 4. Waterproof Mortars: Enhanced water retention and impermeability for industrial tanks and pools—meeting EN 14891 crack-bridging standards.

- 5. Cement Renders/Wall Putty: RDP improves workability, reduces dusting, and increases smoothness, ideal for decorative applications.

Experience: Leading general contractors in Southeast Asia have reported up to 35% reduced post-installation surface failures when switching to Yaguan Redispersible Polymer Powder (RDP).

- Energy Saving: Reduced curing temperature, less water demand – eco-friendly by design.

- Corrosion Resistance: In builds for the petrochemical and wastewater sector, RDP improves surface protection and reduces repair frequency.

- Sustainability: Supports the construction of green-certified buildings (LEED, BREEAM mentioned in project case studies).

| Manufacturer | Annual Capacity (MT) | Key Polymer | Film-Forming Temp (°C) | Bond Strength (MPa) | Certifications | Warranty |

|---|---|---|---|---|---|---|

| Yaguan | 30,000 | EVA | 2 | 1.51 | ISO 9001:2015, CE | 2 Years |

| Wacker | 100,000+ | EVA, VaE | 3 | 1.49 | ISO 9001 / 14001 | 1 Year |

| VINNAPAS | 70,000 | VaE | 5 | 1.46 | ISO 9001, REACH | 1 Year |

| Sinopec | 35,000 | EVA | 6 | 1.35 | ISO 9001 | 1 Year |

- Yaguan offers strong customization, rapid production cycles (ready in 10–15 days), and direct technical support; competitive advantage in lead-time and technical flexibility.

- All major players comply with international certifications (ISO, REACH, CE) and provide batch COA and MSDS.

Customized Formulation: Yaguan supports tailored Redispersible Polymer Powder (RDP) development to meet customers’ different needs in tensile strength, flexibility, setting time, and water retention.

- Multiple gradations optimized for high flexibility, ultra-white construction, or faster setting time (custom MFFT and film strength).

- OEM label and packaging, private formula development, and support for test batches – from 500 kg.

- Technical service for on-site adjustment and application consultation.

Delivery Period: Standard 20MT order is delivered within 10–15 days after order confirmation (FOB Chinese main ports).

Warranty & Support: 2-year product quality guarantee; complete documentation (COA, MSDS, logistic traceability). 24h application engineer hotline for post-sale technical support.

A: The majority of industrial Redispersible Polymer Powder (RDP) are based on Ethylene-Vinyl Acetate (EVA) or Vinyl Acetate-Ethylene (VaE) copolymers, chosen for their excellent balance of adhesion, flexibility, and hydrophobicity.

A: Particle size generally ranges from 80–130 μm; solid content is ≥98% (measured by ISO 3251 gravimetric method).

A: Major standards include ISO 9001:2015 (quality management), ASTM C605 for dry-mix mortars, and EN 12004 for adhesives.

A: Standard construction RDP is not certified for food contact. However, food-grade polymers can be supplied upon request (please specify for FDA/EC compliance).

A: Store in a cool, dry, and ventilated space, avoiding sunlight and moisture. Sealed RDP has a shelf-life of up to 24 months.

A: RDP is compatible with Hydroxypropyl Methylcellulose (HPMC), calcium formate, defoamers, and most construction additives. Pre-mix testing is recommended.

A: Yes, custom RDP is available (e.g., low MFFT, ultra-flexibility, pigmentation resistance, higher redispersibility). Contact Yaguan’s technical team to discuss your formulation needs.

- Certifications: Product conforms to ISO 9001:2015, passes RoHS/REACH, and meets CE/EN compliance for construction chemicals.

- Industry Partners: Regular supplier to listed firms in China, Southeast Asia, the EU, and the Middle East. Key partners include Mapei, Asian Paints, Xella.

- Service Years: Over 15 years in RDP production and international trade, exporting to 40+ countries.

- References: Product specifications and performance independently tested and referenced in Elsevier Construction and Building Materials.

- Delivery: Full batch-traceability and third-party inspection support available.

Market and technical data quoted from industry leaders: Mordor Intelligence & ResearchGate.

Pervious