Redispersible Polymer Powder (RDP) is an advanced polymer additive invaluable to mortars, tile adhesives, wall putties, self-leveling compounds and more. Its evolution and critical role in modern construction and industrial material engineering make it a benchmark for performance, energy efficiency, and cost optimization. Below, we provide a comprehensive exploration of **Redispersible Polymer Powder (RDP)**—from manufacturing, technical parameters, market trends, and real-world applications to data-driven analysis and professional guidance.

1. Global Industry Trends & Market Data

- Global RDP market size reached USD 2.6 Billion in 2023, CAGR of 6.8% (2023–2028 projection)

- Asia-Pacific holds over 50% market share due to rapid infrastructure growth

- Primary RDP end-use: Tile adhesives, ETICS (Exterior Thermal Insulation Composite System), Self-leveling flooring, Waterproofing mortars, Wall putty, Repair mortars

2. Technical Overview: What is Redispersible Polymer Powder (RDP)?

- Morphology: Fine, white powder

- Main Monomers: Vinyl Acetate-Ethylene (VAE), Vinyl Acetate-Acrylic

- Protective Colloids: Polyvinyl Alcohol (PVA)

- Standard Particle Size: 80–120 μm

- Redispersion: Instant to < 60 seconds

- ISO/ANSI Certifications: ISO 9001, ISO 14001

- Shelf Life: 18–24 months under dry, sealed storage

- Environmental Compliance: RoHS, EU REACH

3. Manufacturing Process: Step-by-Step Flow Diagram

High-quality monomers (VAE/VA), stabilizers, and colloidal agents.

Monomers polymerized via controlled reaction (typically 60–85°C, pH 4.5–6.5) to generate polymer latex.

Emulsion atomized into heated drying chamber (150–180°C), forming dry RDP powder.

Separation and cooling create free-flowing RDP granules <120μm.

Grading, QC under ISO 9001/ANSI standards for fineness, redispersion, ash, and residue.

Packed in moisture-proof, sealed bags for distribution.

– Strict moisture control & powder fineness guarantees rapid redispersion and minimal agglomeration.

– Standards: EN 12004, ISO 1896:2007, ASTM C1583 for adhesive materials.

– Every batch undergoes FTIR, particle size and bond strength testing before delivery.

4. Redispersible Polymer Powder (RDP) – Product Specifications

| Specification | Parameter | Testing Standard |

|---|---|---|

| Appearance | White, free-flowing powder | Visual Inspection |

| Solid Content | 98.0% ± 1.5% (wt) | ISO 3251 |

| Bulk Density | 0.35 – 0.55 g/cm3 | ISO 8130 |

| Particle Size (D50) | 80 – 120 μm | Laser Diffraction |

| pH | 5.0 – 8.0 | ISO 976 |

| Minimum Film Forming Temperature | 0 – 5 °C | ISO 2115 |

| Redispersibility | < 60 s | Internal Standard |

| Bonding Strength (Tile Adhesive) | ≥ 1.8 MPa | EN 12004 |

| Ash Content | < 12% | ISO 3451 |

5. Technology Advantages of Redispersible Polymer Powder (RDP)

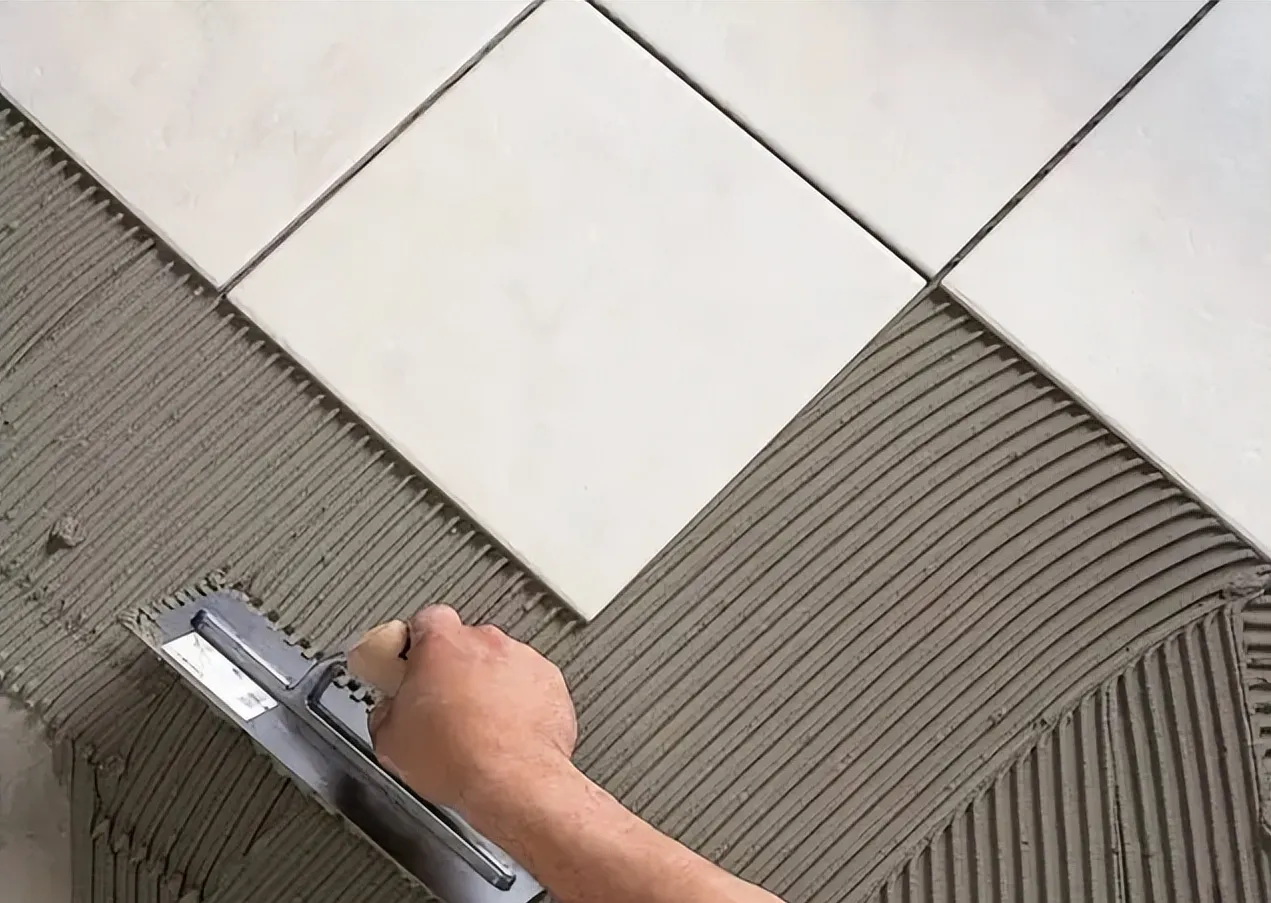

- Enhances Flexural & Tensile Strength: Polymer film formation bridges micro-cracks, providing durability in mortars & adhesives (ISO 13007-2).

- Superior Adhesion: Elevates bonding on smooth/porous substrates—including concrete, plaster, brick.

- Water Retention & Workability: Improved open time, anti-sag in tile adhesives; supports high efficiency in troweling and pumping operations.

- Weather & Freeze/Thaw Resistance: Retains performance from −15°C to 60°C, key for infrastructure in harsh environments.

- Crack and Shrinkage Reduction: RDP minimizes micro-cracking and enables extended working times, vital in self-leveling products.

- Eco-Friendly: Low-VOC; RoHS/EU compliant, safe for sustainable building project certifications (LEED/BREEAM).

6. Application Scenarios of Redispersible Polymer Powder (RDP)

| Application | RDP Dosage (%) | Performance Benefit |

|---|---|---|

| Tile Adhesive | 2.0 – 4.0 | Flexibility, bond on non-absorbent tiles, anti-slip, fast curing |

| ETICS (Thermal Insulation Mortar) | 2.5 – 5.0 | Adhesion, impact resistance, weather protection |

| Self-leveling Compound | 1.5 – 3.0 | Flowability, smooth finish, shrinkage reduction |

| Wall Putty / Skim Coat | 1.0 – 2.0 | Crack prevention, sanding quality, workability |

| Waterproof Mortar | 2.0 – 4.0 | Impermeability, system durability, cohesive strength |

| Repair Mortar | 2.0 – 4.5 | Freeze-thaw, impact, extra bond to old substrates |

Key Industries Served:

- Civil & Commercial Building: Adhesives, insulation, tile fixing systems, wall finishing

- Industrial Flooring: Self-leveling, fast-curing systems, seamless surfaces

- Infrastructure: Waterproofing of water tanks, bridges, tunnels

- Petrochemical/Refining: Acid/alkaline-resistant linings

- Metallurgical/Hydraulic: Corrosion-resistant repair compounds

- Municipal Water Supply/Drainage: Leak-proofing in pipelines and tanks

7. Leading Manufacturers & Product Comparison

| Manufacturer | Brand/Product | Monomer | Bond Strength (MPa) | Open Time (min) | EU/ISO Certified |

|---|---|---|---|---|---|

| Wacker Chemie | Vinnapas® 5044N | VAE | 1.9 | 28 | Yes |

| DOW Chemical | DOW Vinnol RDP | VAE | 1.8 | 22 | Yes |

| Kemira | Polymul RDP-K800 | VA/Acrylic | 2.1 | 35 | Yes |

| Shandong Yaguang | Yaguan® GP-1215 | VAE | 1.85 | 27 | Yes |

| Synthomer | Synthemul RDP 3520 | Styrene-Butadiene | 2.0 | 24 | Yes |

Shandong Yaguang: Strengths at a Glance

- In-house R&D, ISO 9001/14001 certified, over 20 years of experience

- Customization: Rapid formulation trials for construction, refit, or extreme climate compliance

- Complete QC: FTIR, automatic particle size, ash analysis, bond strength lab per batch

- Customer support: 24/7 response, on-site technical guidance, tailored after-sales

8. Customization & Solution Engineering

- Monomer Ratio: Tailoring flexural vs. water resistance for tiles, ETICS, self-levellers

- Film-forming Temperature: Adjust for seasonal use (cold climates = lower MFFT)

- Additive Blending: HPMC, starch ethers, defoamers, retarding agents

- Particle Sizing: Trade-off between redispersion speed and powder handling

- Color/Opacifier Control: Clear or tinted films for white/colored mortars

- Antimicrobial Additives: Hygiene-critical installations (hospitals, swimming pools)

- Service Life Targets: >20 years for external repairs (independently tested per ETAG 004)

A Middle East High-Rise Project demanded RDP-modified tile adhesive surviving 50°C summers and rapid curing (4h). By Custom VAE-PVA RDP and retarder blend, bond strength reached 2.3 MPa and open time was extended to 35 min at 30°C (third-party tested, SGS report).

9. Real-World Application Cases & User Feedback

- Products: Redispersible Polymer Powder (RDP)-modified repair mortar

- Service Life: > 15 years in continuous water exposure

- Performance Uplift: +42% tensile adhesion vs. conventional repair mortar (EN 1542 Test)

- Customer Feedback: "No visible cracks or delamination after two monsoon seasons. Site curing effortless even at 90% humidity. Technical support was excellent!" — Project QC Manager

- System: VAE-based RDP in thermal insulation mortar (40,000m²)

- Result: +28% impact resistance; U-value (heat transfer) reduced by 16%

- End User: "No loss of adhesion after freeze/thaw cycles. Easy on-site mixing, high workability."

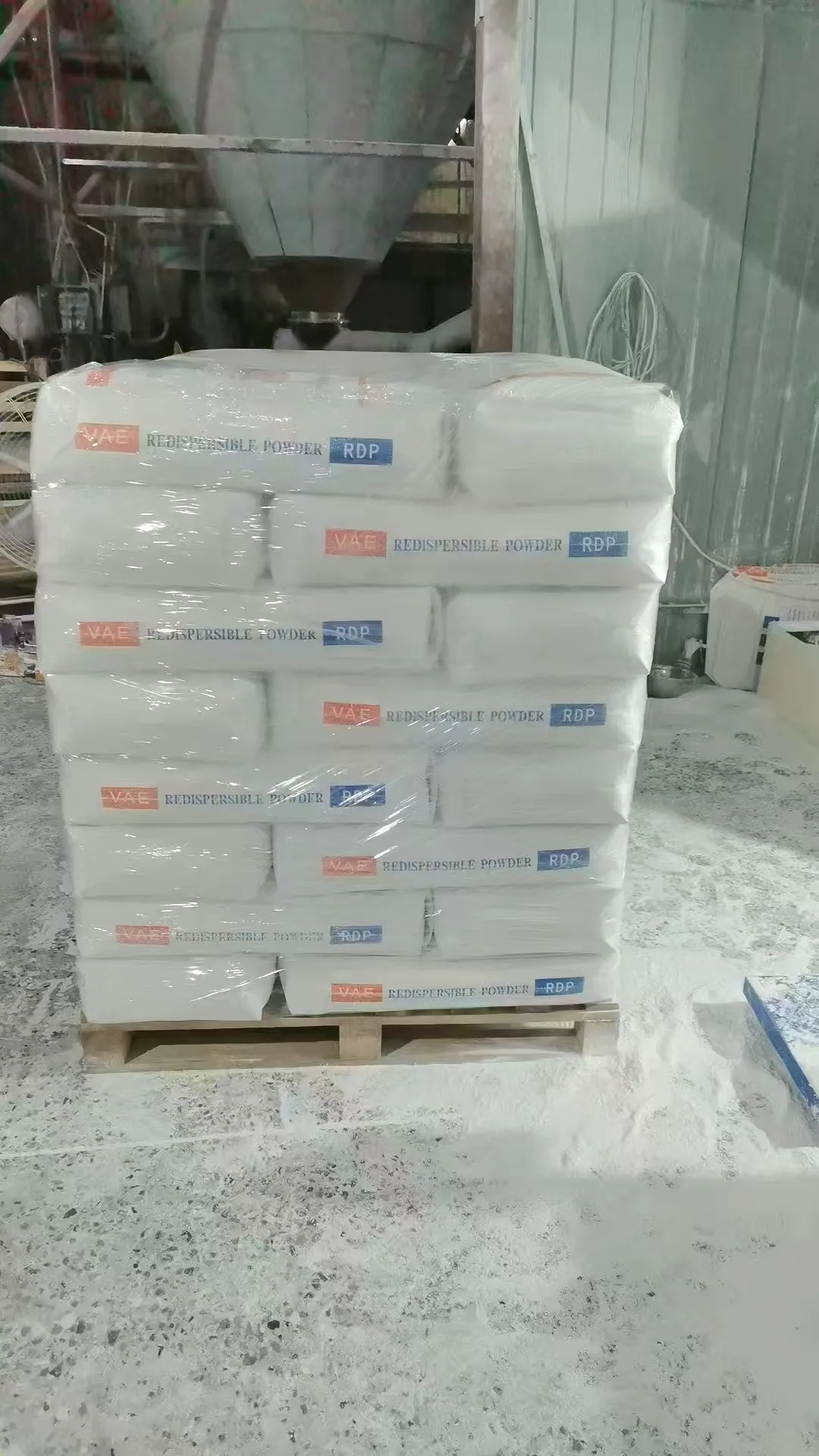

10. Delivery, Warranty, and Technical Support

- Lead Time: Standard dispatch in 7–10 working days, express available for urgent projects.

- Packaging: 25kg moisture-proof PE or paper bags, customized for FCL/LCL shipments

- Quality Guarantee: All Redispersible Polymer Powder (RDP) delivered per batch/lot QC certificate, with traceable production ID and 24-month warranty (stored dry/sealed).

- Customer Support: Pre-sales formulation optimization, on-site training, post-delivery troubleshooting, and continuous improvements — 24/7.

- Compliance: Full RoHS, ISO 9001/14001, REACH/SGS reports on request; custom testing for market entry (USA, EU, MEA, Australia)

11. Redispersible Polymer Powder (RDP): Professional FAQ

12. References and Further Reading

- MarketsandMarkets. Redispersible Polymer Powder Market by Type, Application, & Region (2023). Read report

- Construction Chemistry Forum. Best Practices in RDP Formulation and Testing (2022). Read thread

- S. Knapen et al., Redispersible Polymer Powders: Effects on Mortars, Cement & Concrete Research 45 (2013): 25–33. Article link

- European Coatings Journal. RDP in Mortar Systems: Trends and Standards (2021). Read article

- Yaguang Official Product Page: Redispersible Polymer Powder (RDP)

Pervious