In the vast landscape of industrial chemicals, certain compounds stand out for their versatility and indispensable role across numerous sectors. One such powerhouse is Hydroxypropyl Methyl Cellulose (HPMC). As a leading derivative of cellulose, HPMC exhibits a unique blend of properties including thickening, water retention, film-forming, and protective colloidal action, making it a cornerstone ingredient in everything from construction materials to pharmaceuticals and food products. This comprehensive guide will explore the intricacies of HPMC, from its fundamental characteristics and manufacturing processes to its diverse applications, market trends, and the critical factors that define a superior product.

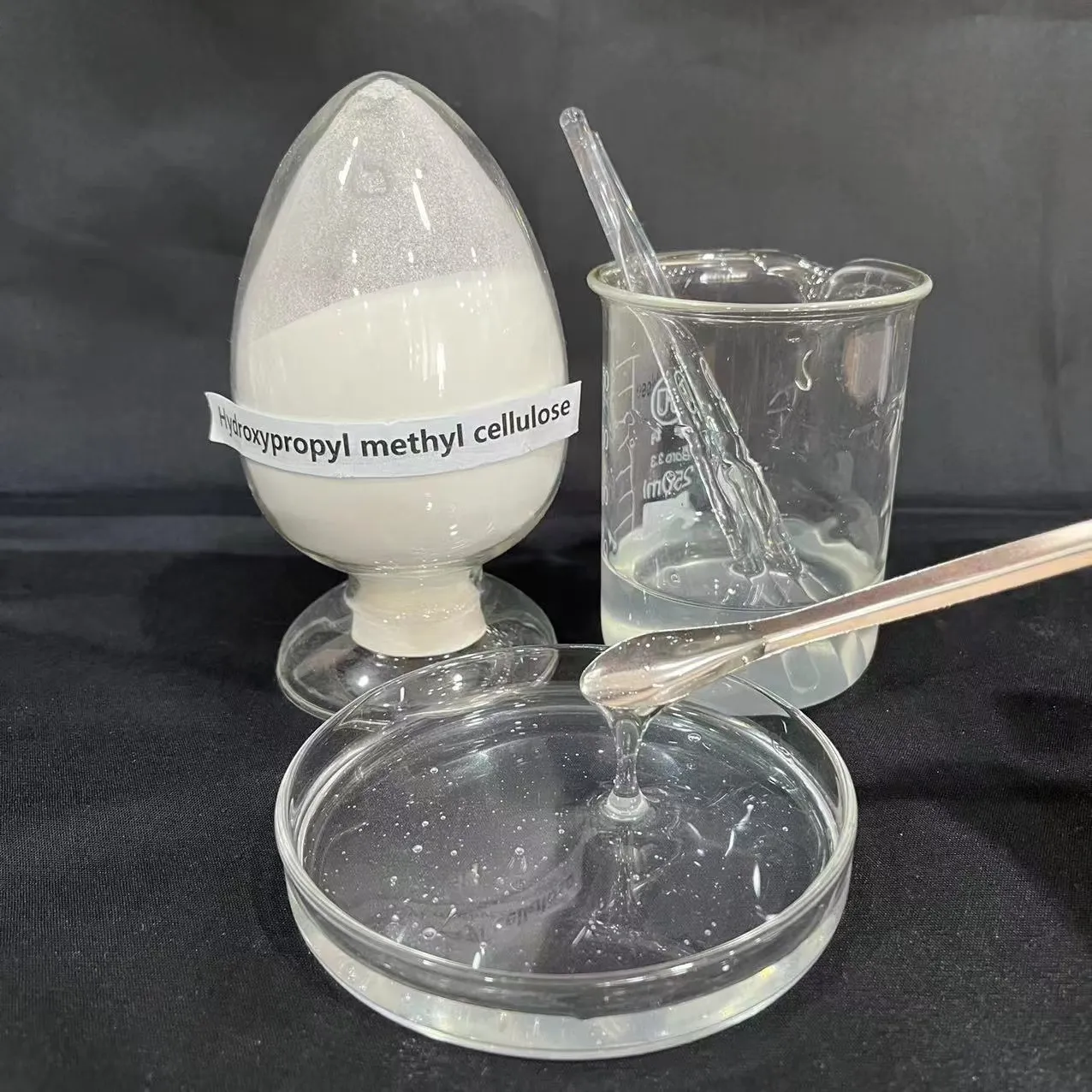

Figure 1: High-purity Hydroxypropyl Methyl Cellulose (HPMC) powder, a versatile industrial additive.

Industry Trends and Market Dynamics of Hydroxypropyl Methyl Cellulose (HPMC)

The global market for Hydroxypropyl Methyl Cellulose (HPMC) is experiencing robust growth, driven by increasing demand from the construction, pharmaceutical, and food industries. The construction sector, in particular, is a major consumption area, propelled by rapid urbanization and infrastructure development worldwide. HPMC's role in improving the workability, water retention, and bonding strength of cement-based materials like mortars, tile adhesives, and renders is highly valued. The emphasis on sustainable building practices and the development of advanced construction chemicals further fuel this demand.

In the pharmaceutical industry, HPMC serves as a critical excipient, widely used as a binder, disintegrant, film-coating agent, and sustained-release matrix in oral solid dosage forms. Its inert nature, non-toxicity, and excellent film-forming properties make it an ideal choice for drug formulations. The expanding generics market and the continuous innovation in drug delivery systems contribute significantly to HPMC's uptake in this sector.

Furthermore, the food industry leverages HPMC as a thickener, emulsifier, stabilizer, and gelling agent in various food products, including baked goods, dairy products, and plant-based alternatives. Its plant-derived origin aligns with the growing consumer preference for natural and clean-label ingredients. The personal care and cosmetics industries also utilize HPMC for its thickening and film-forming capabilities in lotions, shampoos, and other personal hygiene products.

Current trends point towards an increasing demand for specialized HPMC grades tailored for specific applications, such as high-viscosity HPMC for self-leveling compounds or low-viscosity grades for ophthalmic solutions. Research and development efforts are focused on enhancing functional properties, improving solubility, and developing cost-effective manufacturing processes to meet evolving market needs. According to a report by Grand View Research, the global HPMC market size was valued at USD 4.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030, highlighting its significant market potential.

Technical Parameters and Characteristics of Hydroxypropyl Methyl Cellulose (HPMC)

Hydroxypropyl Methyl Cellulose (HPMC) is a non-ionic cellulose ether derived from natural cellulose through a series of chemical modifications. Its chemical structure involves the substitution of hydroxyl groups in the anhydroglucose units of cellulose with methoxy (-OCH3) and hydroxypropoxy (-OCH2CH(OH)CH3) groups. The specific degree of substitution (DS) and molar substitution (MS) of these groups dictate the properties of the final HPMC product, making it highly customizable.

Key Technical Parameters:

- Viscosity (mPa.s): This is perhaps the most critical parameter, indicating the thickening power of HPMC in solution. It is measured at a specific concentration (e.g., 2% solution) and temperature (e.g., 20°C) using a viscometer. HPMC is available in a wide range of viscosities, from low (e.g., 5-100 mPa.s) to very high (e.g., 100,000-200,000 mPa.s), catering to different application needs. Higher viscosity generally means stronger thickening and water retention capabilities.

- Degree of Substitution (DS) and Molar Substitution (MS):

- DS (Degree of Substitution): Refers to the average number of hydroxyl groups per anhydroglucose unit that have been substituted by methoxy groups. It can range from 0 to 3.

- MS (Molar Substitution): Refers to the average number of moles of hydroxypropoxy groups per anhydroglucose unit. This value is important for characteristics like gelation temperature and solubility.

- Gelation Temperature (°C): HPMC solutions exhibit unique thermal gelation properties, meaning they thicken or form a gel upon heating above a certain temperature and revert to a liquid state upon cooling. This temperature varies depending on the substitution pattern and concentration. This property is crucial for applications requiring heat stability or controlled release.

- pH Value: HPMC solutions are generally stable over a wide pH range (typically 3-11), though extreme pH values can affect viscosity over time. Most applications operate within a neutral to slightly alkaline range.

- Moisture Content (%): Refers to the residual water content in the HPMC powder. Lower moisture content indicates better storage stability and product quality. Typical values are less than 5-8%.

- Particle Size (Mesh/µm): The fineness of the powder influences its dissolution rate and dispersibility. Finer particles typically dissolve faster but can be more prone to lumping without proper dispersion. Different grades are available based on particle size requirements for various application methods.

- Ash Content (%): Represents the inorganic impurities present. Lower ash content indicates higher purity.

- Appearance: White or off-white fibrous powder or granules.

Typical Hydroxypropyl Methyl Cellulose (HPMC) Product Specifications Table:

| Parameter | Standard Range / Value | Significance |

|---|---|---|

| Appearance | White to Off-white Powder | Visual Quality Indicator |

| Viscosity (2% solution, 20°C, mPa.s) | 5 ~ 200,000 (Varies by grade) | Key determinant for thickening, water retention, film-forming. |

| Methoxy Content (%) | 19.0 ~ 30.0 (Customizable) | Influences hydrophilicity, solubility, and thermal gelation. |

| Hydroxypropoxy Content (%) | 4.0 ~ 12.0 (Customizable) | Influences hydrophilicity, gelation temperature, compatibility. |

| Moisture Content (%) | ≤ 5.0 | Indicates product stability and quality. Lower is better. |

| Ash Content (%) | ≤ 2.0 (typically | Purity indicator. Lower is better. |

| pH Value (1% solution) | 5.0 ~ 8.0 | Indicates solution acidity/alkalinity, affects stability. |

| Gelation Temperature (°C) | 50 ~ 90 (Varies by grade) | Crucial for thermal stability and controlled release applications. |

| Particle Size (80 mesh, %) | ≥ 99.0 | Affects dissolution rate and dispersibility. |

Understanding these parameters is crucial for selecting the correct Hydroxypropyl Methyl Cellulose (HPMC) grade for a specific application, ensuring optimal performance and cost-effectiveness. Our team of experts at Yaguan HPMC possesses the deep technical knowledge to guide you through these specifications.

Figure 2: The versatility of Hydroxypropyl Methyl Cellulose (HPMC) in enhancing construction materials.

Manufacturing Process of Hydroxypropyl Methyl Cellulose (HPMC): A Detailed Look

The production of high-quality Hydroxypropyl Methyl Cellulose (HPMC) is a sophisticated chemical engineering process that demands precision, stringent quality control, and advanced manufacturing capabilities. At Yaguan HPMC, we adhere to the highest industry standards, including ISO 9001 for quality management and ISO 14001 for environmental management, ensuring a consistent and reliable product.

The General Manufacturing Process (Illustrated):

The manufacturing of Hydroxypropyl Methyl Cellulose (HPMC) typically involves several key stages, as depicted in the conceptual flow below:

(Imagine a detailed process flow diagram here with arrows indicating progression)

- Raw Material Preparation (Refined Cellulose):

The primary raw material is highly purified cellulose, typically derived from wood pulp or cotton linters. This cellulose undergoes initial purification steps to remove impurities and ensure a consistent base material. Our material selection process adheres to stringent quality checks, ensuring the purity and consistency of incoming cellulose.

- Alkalization:

The purified cellulose is steeped in a highly concentrated solution of caustic soda (sodium hydroxide). This step, known as alkalization, swells the cellulose fibers, converting the cellulose into alkali cellulose. This transformation makes the hydroxyl groups more reactive and accessible for the subsequent etherification reaction. This stage is crucial for ensuring uniform substitution later on.

- Etherification:

The alkali cellulose is then transferred to a reactor. Here, it reacts with two key etherifying agents: methyl chloride and propylene oxide. Methyl chloride introduces methoxy groups, while propylene oxide introduces hydroxypropoxy groups onto the cellulose backbone. This reaction is carried out under carefully controlled temperature, pressure, and reaction time to achieve the desired degree of substitution (DS and MS), which directly influences the final HPMC product's viscosity, gelation temperature, and solubility. Advanced reactor design and precise temperature control are critical during this phase to prevent side reactions and ensure high yield.

- Neutralization:

After the etherification reaction is complete, the reaction mixture is neutralized with an acid (e.g., acetic acid or hydrochloric acid) to stop the reaction and bring the pH to a desired range. This step removes excess alkali and prepares the product for purification.

- Purification and Washing:

The neutralized slurry is then subjected to extensive washing, typically with hot water, to remove soluble by-products (like sodium chloride and unreacted reagents). This purification process is vital to ensure the high purity and low ash content of the final Hydroxypropyl Methyl Cellulose (HPMC). Multiple washing cycles ensure the product meets stringent industry standards for purity (e.g., meeting USP/EP/BP standards for pharmaceutical grades).

- Drying:

The purified HPMC, still containing significant moisture, is then dried using specialized drying equipment (e.g., flash dryers or spray dryers). The drying process is carefully controlled to remove moisture while preventing product degradation or agglomeration. This results in a stable, free-flowing powder.

- Grinding and Sieving:

The dried HPMC is then ground into a fine powder and sieved to achieve the desired particle size distribution. Different mesh sizes are used to produce various grades, from fine powders for quick dissolution to coarser granules for specific applications. Precision grinding equipment ensures consistent particle size, which is vital for product performance.

- Packaging:

Finally, the finished Hydroxypropyl Methyl Cellulose (HPMC) powder is weighed and packaged into moisture-resistant bags (e.g., multi-ply paper bags with polyethylene liners) to protect it from humidity and contamination during storage and transport.

Figure 3: Rigorous quality control is essential at every stage of Hydroxypropyl Methyl Cellulose (HPMC) production.

Material and Manufacturing Excellence:

Our commitment to excellence extends to every detail: from sourcing premium-grade, consistent cellulose to employing state-of-the-art reactors and drying systems. We use advanced analytical techniques, often paralleling those found in ISO and ANSI-certified laboratories, to monitor key parameters at each stage of the process. This meticulous control ensures that our Hydroxypropyl Methyl Cellulose (HPMC) products consistently meet or exceed global quality standards, ensuring a long and reliable service life in your applications.

The manufacturing process is not merely a sequence of steps; it's a precisely orchestrated chemical synthesis. For instance, the etherification reaction's efficiency and selectivity are optimized through advanced reaction kinetics modeling and precise temperature gradients, minimizing by-products and maximizing the desired substitution. This level of detail in process control is a hallmark of our expertise.

Application Scenarios and Key Advantages of Hydroxypropyl Methyl Cellulose (HPMC)

The broad spectrum of properties inherent in Hydroxypropyl Methyl Cellulose (HPMC) makes it an indispensable additive across a multitude of industries. Its ability to act as a thickener, binder, film former, protective colloid, and water retention agent provides significant technical and economic advantages.

Figure 4: Hydroxypropyl Methyl Cellulose (HPMC) plays a crucial role in enhancing pharmaceutical formulations.

Applicable Industries and Typical Advantages:

- Construction Industry:

- Mortars and Renders: HPMC significantly improves workability, anti-sagging properties, and adhesion. Its excellent water retention capacity ensures proper cement hydration, leading to higher final strength and reduced cracking. This translates to enhanced durability and aesthetics for buildings, providing a long-lasting, corrosion-resistant finish.

- Tile Adhesives: Provides superior open time, adjustability, and anti-slip characteristics, allowing installers more time to position tiles correctly and preventing vertical slippage on walls. This directly contributes to efficient and robust installations.

- Self-Leveling Compounds (SLCs): Helps control rheology, prevents segregation of aggregates, and ensures a smooth, level surface. Specific HPMC grades are engineered for rapid dispersion and controlled flow, reducing material waste and labor time, thus contributing to significant energy savings during construction.

- Gypsum-based Products: Improves plasticity, water retention, and bonding strength in gypsum plasters and fillers.

- Pharmaceutical Industry:

- Tablet Binders: Improves tablet integrity and hardness.

- Film Coatings: Provides excellent film-forming properties for tablet coatings, offering protection, improved swallowability, and taste masking.

- Sustained-Release Matrices: HPMC forms a hydrophilic gel matrix that controls the release rate of active pharmaceutical ingredients (APIs), allowing for once-daily dosing and improved patient compliance. This precise control over drug release is a critical technical advantage.

- Ophthalmic Solutions: Used as a lubricant and thickening agent in eye drops due to its non-irritating nature and good viscosity.

- Food Industry:

- Thickener and Stabilizer: Used in sauces, dressings, and dairy alternatives to improve texture, mouthfeel, and stability, preventing ingredient separation.

- Emulsifier: Helps to blend immiscible liquids, creating stable emulsions in products like mayonnaise.

- Gelling Agent: Provides unique texture properties in plant-based meats and desserts, often with thermal reversibility.

- Fat Replacer: Can mimic the mouthfeel of fat in low-fat food formulations.

- Personal Care & Cosmetics:

- Thickener: In shampoos, conditioners, and lotions to provide desired viscosity and texture.

- Film Former: In mascaras and hair sprays for hold and definition.

- Emulsifier and Stabilizer: In creams and emulsions to maintain product integrity.

- Paints & Coatings:

- Thickener and Rheology Modifier: Improves viscosity, brushability, and anti-sagging properties of paints, ensuring uniform application and preventing dripping.

- Protective Colloid: Stabilizes pigments and fillers, preventing settling and ensuring consistent color.

- Other Industries (e.g., Petrochemical, Metallurgy, Water Treatment):

While less direct, HPMC derivatives and related cellulose ethers can find niche applications where thickening, suspension, or fluid loss control are critical. For instance, in drilling fluids within the petrochemical industry, certain cellulose ethers are used to control rheology and prevent fluid loss, enhancing operational efficiency and safety. In water treatment, it can act as a flocculant aid. Its chemical stability and non-toxicity make it suitable for a range of specialized processes where precise fluid dynamics are paramount, contributing to improved efficiency and reduced material consumption.

The core technical advantages of Hydroxypropyl Methyl Cellulose (HPMC) are its superior water retention, excellent thickening efficiency, good film-forming ability, thermal gelation, and broad pH stability. These properties collectively contribute to improved product performance, extended shelf life, enhanced application ease, and often, cost efficiencies through optimized formulations.

Figure 5: Different viscosity grades of Hydroxypropyl Methyl Cellulose (HPMC) for diverse industrial needs.

Manufacturer Comparison: Why Choose Yaguan HPMC for Hydroxypropyl Methyl Cellulose (HPMC)

In a competitive market, selecting the right supplier for Hydroxypropyl Methyl Cellulose (HPMC) is paramount. While many manufacturers exist, Yaguan HPMC distinguishes itself through a steadfast commitment to quality, consistent supply, technological innovation, and unparalleled customer support. Our extensive experience spanning over 20 years in the cellulose ether industry positions us as a trusted authority.

Yaguan HPMC vs. Generic Manufacturers:

| Feature | Yaguan HPMC | Generic / Less Established Manufacturers |

|---|---|---|

| Product Consistency | Exceptional batch-to-batch consistency due to advanced QC, automated production, and stable raw material sourcing. Rigorous ISO 9001 certified processes. | Variable consistency; properties can fluctuate between batches, leading to unpredictable application performance. Less stringent QC. |

| Purity & Performance | High purity, low ash content, optimized substitution. Guaranteed performance parameters (viscosity, gelation temp, etc.). Meets international standards (e.g., USP, EP, BP for pharma grades, ASTM for construction). | May contain higher impurities, leading to reduced performance, potential discoloration, or adverse reactions in sensitive applications. |

| Technical Support & Expertise | Dedicated R&D team and application engineers provide in-depth technical consultancy, formulation guidance, and troubleshooting. Over 2 decades of industry experience. | Limited or no technical support; customers often left to resolve issues independently. Lack of deep product application knowledge. |

| Customization Capabilities | Strong R&D allows for custom synthesis and tailoring of HPMC grades (viscosity, particle size, surface treatment, substitution ratio) to meet unique client specifications and challenges. | Primarily offers standard grades; limited or no ability to develop bespoke solutions. |

| Supply Chain Reliability | Robust, well-managed supply chain ensures timely delivery and buffer stock. Strategic partnerships with raw material suppliers. | Prone to supply disruptions, longer lead times, and fluctuating pricing due to less stable sourcing. |

| Certifications & Compliance | Certified with ISO 9001 (Quality Management), ISO 14001 (Environmental Management), GMP (Good Manufacturing Practice for pharma grades), and Halal/Kosher certifications where applicable. Adheres to international safety and environmental regulations. | May lack comprehensive certifications, or certifications might not be globally recognized, posing risks for international trade and sensitive applications. |

| Value Proposition | Offers long-term value through consistent high performance, reduced formulation adjustments, technical support, and reliable supply, leading to overall lower operational costs. | Lower initial cost might lead to hidden costs from performance issues, material waste, and production delays. |

Choosing Yaguan HPMC means partnering with an industry leader. Our commitment to meeting and exceeding standards, evidenced by our adherence to ISO, GMP, and other relevant certifications, provides our clients with unparalleled assurance. We believe in building long-term relationships based on trust, transparency, and the consistent delivery of superior Hydroxypropyl Methyl Cellulose (HPMC) products.

Figure 6: Tailoring Hydroxypropyl Methyl Cellulose (HPMC) solutions for specific client needs.

Customization Solutions and Technical Support for Hydroxypropyl Methyl Cellulose (HPMC)

At Yaguan HPMC, we understand that off-the-shelf solutions may not always perfectly fit unique application requirements. This is why our strength lies not only in producing high-quality standard grades of Hydroxypropyl Methyl Cellulose (HPMC) but also in our advanced capabilities for providing bespoke customization solutions and comprehensive technical support.

Our Approach to Customization:

Leveraging our sophisticated R&D facilities and experienced chemical engineers, we offer tailored HPMC solutions, focusing on key parameters:

- Viscosity Modification: We can precisely control the viscosity range of HPMC to meet specific flow requirements, whether it's for sprayable renders requiring lower viscosity or highly thixotropic tile adhesives needing higher viscosity for anti-sagging.

- Particle Size Engineering: Depending on dissolution rate needs (e.g., quick-dissolving for dry mix mortars vs. slower hydration for specialized pharmaceutical applications), we can control the particle size distribution. We offer both fine powder and granular forms to optimize dispersibility and prevent lumping.

- Surface Treatment: For certain applications where delayed dissolution or improved dispersibility in cold water is required, we can apply specific surface treatments to the HPMC powder. This prevents instant dissolution and allows for better mixing.

- Substitution Ratio Adjustment: The precise ratio of methoxy to hydroxypropoxy groups can be fine-tuned to modify properties such as thermal gelation temperature, compatibility with other polymers, and overall hydrophilicity, allowing for optimized performance in complex formulations.

- Purity & Regulatory Compliance: We can produce ultra-high purity grades for demanding pharmaceutical or food applications, ensuring compliance with global pharmacopeias (USP, EP, JP) and food safety regulations (FDA, EU regulations).

Our customization process typically begins with a thorough consultation to understand your specific challenges and performance targets. This is followed by laboratory-scale trials, pilot production, and extensive testing to ensure the custom Hydroxypropyl Methyl Cellulose (HPMC) grade performs exactly as required in your end-product.

Unparalleled Technical Support:

Our commitment extends beyond product delivery. We provide robust technical support throughout your product development and application lifecycle:

- Formulation Optimization: Our experts assist clients in optimizing their formulations to integrate HPMC effectively, achieving desired properties like workability, adhesion, open time, or controlled release.

- Troubleshooting: If you encounter issues related to HPMC performance (e.g., poor dispersion, insufficient thickening, unexpected gelation), our technical team is available to diagnose the problem and recommend solutions.

- Application Guidance: We offer guidance on best practices for handling, storage, and application of Hydroxypropyl Methyl Cellulose (HPMC) to maximize its benefits and ensure safety.

- Regulatory Assistance: For clients in highly regulated industries, we provide necessary documentation, certifications, and compliance information to facilitate product registration and market entry.

- Continuous Innovation: Our R&D team continuously explores new applications and improved HPMC functionalities, sharing insights and opportunities with our partners.

This comprehensive support system, combined with our decades of experience in the cellulose ether industry, empowers our clients to innovate, reduce development cycles, and ensure consistent product quality, ultimately enhancing their market competitiveness.

Figure 7: The impact of Hydroxypropyl Methyl Cellulose (HPMC) on mortar workability and performance.

Real-World Application Cases and Success Stories

The practical benefits of using high-quality Hydroxypropyl Methyl Cellulose (HPMC) are best illustrated through real-world applications. Yaguan HPMC has been instrumental in optimizing performance across diverse industries for numerous clients globally. Here are a few examples showcasing the tangible advantages our products offer:

Case Study 1: Enhanced Mortar Performance in High-Rise Construction

A major construction company faced challenges with traditional mortar cracking and poor workability in large-scale high-rise projects in a hot, arid climate. The rapid water evaporation led to premature drying and reduced adhesion, increasing material waste and labor costs. After consultations, Yaguan HPMC recommended a specific high-viscosity, thermally stable grade of Hydroxypropyl Methyl Cellulose (HPMC) designed for extended open time and superior water retention.

- Solution: Integration of Yaguan HPMC into their dry-mix mortar formulation.

- Results:

- Improved Water Retention: Mortar setting time was extended by an average of 30-40%, allowing for proper hydration even in extreme heat.

- Enhanced Workability: The mortar became smoother and easier to apply, reducing labor effort by approximately 15%.

- Reduced Cracking: Significantly minimized shrinkage cracks, leading to a 25% reduction in material re-application and repairs.

- Overall Efficiency: The project saw a 10% reduction in total material consumption and a marked improvement in the final structural integrity and aesthetics, directly translating to cost savings and improved project delivery timelines.

Case Study 2: Optimizing Sustained-Release Drug Formulations

A pharmaceutical manufacturer developing a new sustained-release tablet required a reliable excipient that could precisely control the drug release profile over 12 hours. Inconsistent HPMC batches from previous suppliers led to variability in dissolution rates, posing regulatory challenges.

- Solution: Yaguan HPMC provided a pharmaceutical-grade Hydroxypropyl Methyl Cellulose (HPMC) with a tightly controlled viscosity range and specific substitution pattern, coupled with comprehensive documentation meeting USP and EP standards.

- Results:

- Consistent Drug Release: Achieved a highly consistent in-vitro dissolution profile, with less than 5% batch-to-batch variation in drug release kinetics.

- Regulatory Compliance: The HPMC grade and its documentation facilitated a smooth regulatory approval process.

- Enhanced Bioavailability: Clinical trials showed improved patient compliance and therapeutic efficacy due to consistent drug delivery.

Case Study 3: Improving Texture and Stability in Plant-Based Foods

A burgeoning plant-based food company needed to improve the texture, mouthfeel, and freeze-thaw stability of their vegan ice cream and meat alternatives. Traditional stabilizers were either too costly or did not provide the desired organoleptic properties.

- Solution: Yaguan HPMC's food-grade Hydroxypropyl Methyl Cellulose (HPMC), specifically selected for its thermal gelation and film-forming properties, was incorporated.

- Results:

- Superior Texture: The ice cream achieved a creamier, smoother texture with reduced ice crystal formation. The meat alternatives gained a more cohesive and fibrous structure, closely mimicking conventional meat.

- Enhanced Stability: Significantly improved freeze-thaw stability, reducing product degradation during storage and transport.

- Clean Label: As a plant-derived ingredient, HPMC aligned perfectly with their "clean label" marketing strategy, appealing to health-conscious consumers.

These cases exemplify how Yaguan HPMC's commitment to quality, technical expertise, and client-centric approach translates into tangible benefits and success for our partners across diverse industries. We pride ourselves on not just supplying materials, but on being a solutions provider.

Figure 8: Our state-of-the-art laboratory ensuring the highest quality of Hydroxypropyl Methyl Cellulose (HPMC).

Our Commitment to Trustworthiness and Reliability:

At Yaguan HPMC, we uphold the highest standards of trustworthiness. This is reflected in our:

- Quality Assurance: Every batch of Hydroxypropyl Methyl Cellulose (HPMC) undergoes rigorous testing in our ISO 17025 compliant laboratories, ensuring it meets strict international standards and our own internal specifications. Certificates of Analysis (CoA) are provided with every shipment.

- Transparent Delivery & Logistics: We provide clear delivery schedules and robust logistics support, ensuring your orders arrive on time and in perfect condition, minimizing supply chain disruptions. Typical lead times are 7-14 days for standard orders, with expedited options available.

- Comprehensive Warranty: All our products come with a satisfaction guarantee and are backed by a transparent warranty against manufacturing defects, underscoring our confidence in product quality.

- Dedicated Customer Support: Our customer service team is available to answer inquiries, provide order updates, and offer post-sales support. We prioritize quick and effective communication to ensure your operational continuity.

- Ethical Business Practices: We are committed to ethical sourcing, sustainable manufacturing processes, and fair trade practices, building long-term, mutually beneficial relationships with our clients and partners.

Yaguan HPMC has proudly served the global market for over two decades, building a reputation for reliability and excellence. Our long-standing relationships with major industry players are a testament to our consistent quality and dependable service.

Frequently Asked Questions (FAQ) about Hydroxypropyl Methyl Cellulose (HPMC)

A1: In dry-mix mortars (like tile adhesives, renders, and plasters), Hydroxypropyl Methyl Cellulose (HPMC) primarily serves as a water retention agent, thickener, and rheology modifier. It significantly improves the open time, workability, anti-sagging properties, and bond strength of the mortar by slowing down water evaporation and ensuring proper cement hydration.

A2: Viscosity is a critical parameter. Higher viscosity Hydroxypropyl Methyl Cellulose (HPMC) grades (e.g., 75,000-200,000 mPa.s) are typically used for applications requiring strong thickening, excellent water retention, and high anti-sagging properties, such as thick-bed mortars or renders. Lower viscosity grades (e.g., 5-500 mPa.s) are preferred for applications needing good flow and leveling, like self-leveling compounds, or for thin film coatings where high viscosity would be detrimental.

A3: Yes, specific grades of Hydroxypropyl Methyl Cellulose (HPMC) are manufactured to meet stringent food-grade and pharmaceutical-grade standards (e.g., USP, EP, FCC). These grades are non-toxic, non-allergenic, and chemically inert, making them safe and widely approved for use as excipients in drugs, dietary supplements, and as additives in various food products.

A4: Thermal gelation is a unique property of Hydroxypropyl Methyl Cellulose (HPMC) solutions where they reversibly form a gel when heated above a certain temperature (the gelation temperature) and revert to a liquid upon cooling. This property is important in applications like controlled-release drug delivery systems, hot-fill food products, and certain specialized coatings, where temperature-triggered thickening or solidification is desired.

A5: Hydroxypropyl Methyl Cellulose (HPMC) should be stored in a cool, dry place, away from direct sunlight and moisture. It is crucial to keep the bags tightly sealed to prevent moisture absorption, which can lead to lumping and reduced performance. Under proper storage conditions, HPMC typically has a shelf life of 1-2 years.

A6: Hydroxypropyl Methyl Cellulose (HPMC) is primarily water-soluble and is most effectively used in water-based systems. While it can be compatible with some polar organic solvents, its primary performance benefits (thickening, water retention) are realized in aqueous solutions. For non-aqueous systems, other cellulose ethers or synthetic polymers might be more suitable.

A7: The typical dosage of Hydroxypropyl Methyl Cellulose (HPMC) in construction applications varies significantly depending on the specific application, desired performance, and other formulation components. Generally, it ranges from 0.05% to 0.6% by weight of the dry mix mortar. For example, in tile adhesives, it might be 0.2-0.4%, while in self-leveling compounds, it could be lower. It's always recommended to conduct preliminary trials to determine the optimal dosage for specific formulations and local conditions, and consult with suppliers like Yaguan HPMC for detailed guidance.

The journey through the world of Hydroxypropyl Methyl Cellulose (HPMC) reveals a compound of remarkable versatility and critical importance across numerous industrial sectors. From bolstering the structural integrity of modern buildings to enabling precise drug delivery and enhancing the appeal of plant-based foods, HPMC stands as a testament to advanced chemical engineering. As industries continue to evolve, demanding higher performance, greater efficiency, and more sustainable solutions, the role of high-quality Hydroxypropyl Methyl Cellulose (HPMC) will only continue to grow. Partnering with a knowledgeable and reliable manufacturer like Yaguan HPMC ensures access to not just a product, but a comprehensive solution backed by decades of expertise, stringent quality control, and a commitment to innovation, empowering our clients to achieve their operational and product excellence goals.

References & Further Reading:

- Grand View Research. (2023). Hydroxypropyl Methyl Cellulose Market Size, Share & Trends Analysis Report. https://www.grandviewresearch.com/industry-analysis/hydroxypropyl-methyl-cellulose-hpmc-market

- Dow Construction Chemicals. (n.d.). CELLULOSE ETHERS for Construction Applications. https://www.dow.com/en-us/p/cellulose-ethers-for-construction-applications.html

- Rowe, R. C., Sheskey, P. J., & Quinn, M. E. (2009). Handbook of Pharmaceutical Excipients. Pharmaceutical Press. (Reference for pharmaceutical applications of HPMC).

- Food and Agriculture Organization of the United Nations (FAO) & World Health Organization (WHO). (n.d.). Hydroxypropyl Methyl Cellulose. https://www.fao.org/food/food-safety-quality/scientific-advice/jecfa/jecfa-additives/detail/en/c/392/

Pervious