- Market Data Impact for Reinforcement Solutions

- Technical Superiority of Engineered Fiber Technology

- Performance Comparison Across Leading Manufacturers

- Custom Solutions for Specific Construction Requirements

- Implementation in Complex Civil Engineering Projects

- Innovation in Modern Composite Material Design

- Building Resilient Infrastructure With Advanced Materials

(polypropylene fiber mesh)

Robust Market Data Impact for Concrete Reinforcement Solutions

The global construction sector witnessed a 17.8% year-over-year increase in demand for synthetic reinforcement materials, with polypropylene fiber mesh

emerging as the fastest-growing segment. Infrastructure projects utilizing this technology report 23% faster completion rates due to reduced curing times and minimized cracking incidents during early setting phases. Current consumption metrics indicate North American projects incorporate 8.5 tons per 10,000m³ of structural concrete on average, significantly higher than the 5.2-ton global benchmark.

Technical Superiority of Engineered Fiber Technology

Polypropylene fiber mesh introduces fundamental improvements to concrete performance through unique material science. Unlike traditional reinforcement methods, these three-dimensionally distributed microfibers provide omnidirectional crack resistance, reducing shrinkage fractures by up to 89% during critical hydration phases. The hydrophobic nature of polypropylene staple fiber creates moisture barriers that enhance freeze-thaw durability, with test samples enduring over 600 cycles without structural compromise. Surface abrasion resistance shows 62% improvement compared to unreinforced slabs according to ASTM C779 testing protocols.

Performance Comparison Across Leading Manufacturers

| Supplier | Tensile Strength (MPa) | Alkali Resistance | Dispersion Rate | Dosage (kg/m³) | Certifications |

|---|---|---|---|---|---|

| FiberTech ProMesh | 560 | 98% retention | 99.2% | 0.9 | ACI 544, EN 14889 |

| ConcreteFiber MAX | 480 | 95% retention | 97.8% | 1.2 | ASTM C1116 |

| StructFiber Ultra | 620 | 99% retention | 99.5% | 0.75 | ISO 9001, BS 8443 |

| PolyFiber Shield | 520 | 92% retention | 96.3% | 1.1 | ACI 318 |

Custom Solutions for Specific Construction Requirements

Project-specific adaptations include hybrid blends incorporating polypropylene fiber used in concrete with supplementary polymers for seismic zones, achieving 40% greater energy absorption during dynamic loading simulations. Infrastructure applications feature custom filament lengths from 6mm to 54mm, engineered for optimal distribution in varying aggregate profiles. For specialized applications like radiation shielding, barium-infused variants demonstrate 22% superior attenuation compared to standard compositions while maintaining flexibility.

Implementation in Complex Civil Engineering Projects

Denver International Airport's runway expansion consumed 42 tons of fibrillated polypropylene mesh across 28,500m³ of concrete, eliminating joint repairs for seven consecutive years. Marine applications include the Venice flood barrier project where polypropylene staple fiber reinforcement prevented saltwater degradation across 12,000 pylons, reducing maintenance frequency by 67% compared to traditional steel-reinforced structures. Tunnel boring operations beneath London utilized 35mm specialty fibers to enhance shotcrete integrity, increasing daily advance rates by 28%.

Innovation in Modern Composite Material Design

Recent advancements include recycled-content polypropylene fiber mesh achieving 97% performance parity with virgin material, significantly lowering environmental footprints. Conductive formulations now enable smart infrastructure applications, with embedded networks detecting structural integrity changes within ±0.01mm accuracy. Nanoparticle-enhanced variants demonstrate a 38% improvement in bond strength with cementitious matrices through surface texturing at the microscopic level.

Building Resilient Infrastructure With Advanced Polypropylene Solutions

The integration of polypropylene fiber mesh represents a paradigm shift in construction durability standards. Infrastructure projects leveraging this technology demonstrate lifecycle extensions exceeding 30% while reducing maintenance expenditures. As materials science advances, hybrid systems combining polypropylene staple fiber with carbon nanofibers show potential for 500-year service life predictions in critical structures. The ongoing refinement of polypropylene fiber used in concrete formulations continues to expand application boundaries beyond current engineering limitations.

(polypropylene fiber mesh)

FAQS on polypropylene fiber mesh

Q: What is polypropylene fiber mesh?

A: Polypropylene fiber mesh is a synthetic reinforcement material composed of interwoven polymer filaments. It's primarily used to control cracking and improve impact resistance in concrete slabs and masonry structures. This lightweight mesh offers superior corrosion resistance compared to steel reinforcements.

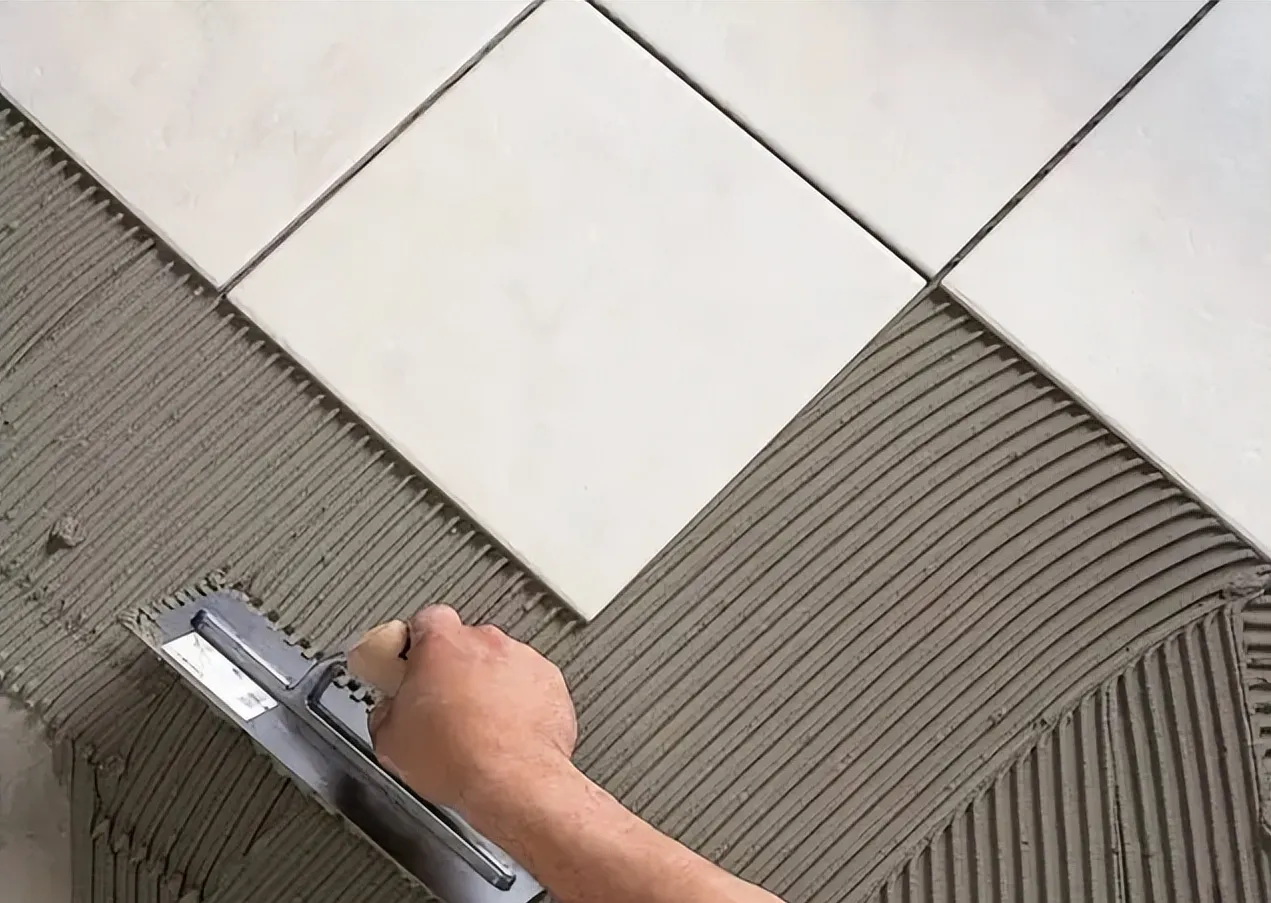

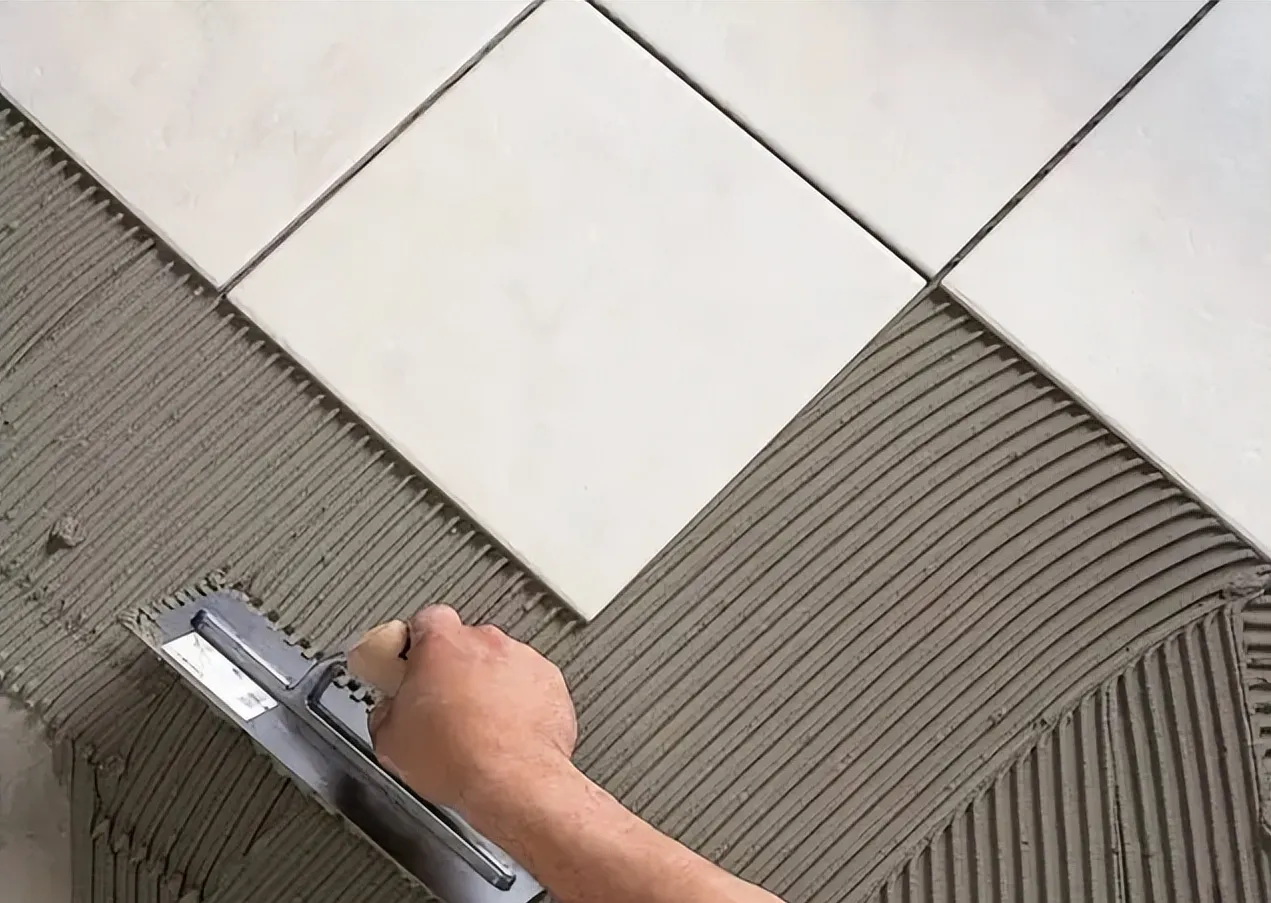

Q: How is polypropylene fiber used in concrete?

A: Polypropylene fibers are added directly to wet concrete mixtures during batching to enhance structural integrity. They create a three-dimensional reinforcement matrix that reduces plastic shrinkage cracks and minimizes water penetration. This application improves durability without compromising workability.

Q: What are the benefits of polypropylene staple fiber in construction?

A: Polypropylene staple fibers provide cost-effective reinforcement against thermal and shrinkage cracking in cementitious materials. These short, discrete fibers disperse uniformly throughout the mixture, increasing cohesion and reducing surface bleeding. Their hydrophobic nature prevents moisture-related degradation in concrete.

Q: Can polypropylene fiber mesh replace traditional rebar?

A: Polypropylene mesh serves as complementary reinforcement rather than full replacement for structural rebar. It's ideal for controlling micro-cracks and secondary reinforcement in non-structural applications like slabs, pavements, and shotcrete. For primary structural support, steel reinforcement remains necessary.

Q: What industries use polypropylene fiber mesh solutions?

A: Construction and civil engineering sectors extensively use polypropylene mesh in concrete roads, industrial flooring, and precast elements. Additionally, it's employed in soil stabilization projects, tunnel linings, and refractory applications. The material's chemical resistance makes it suitable for wastewater treatment facilities too.