Understanding Polypropylene Fiber: A Core Element in Modern Engineering and Construction

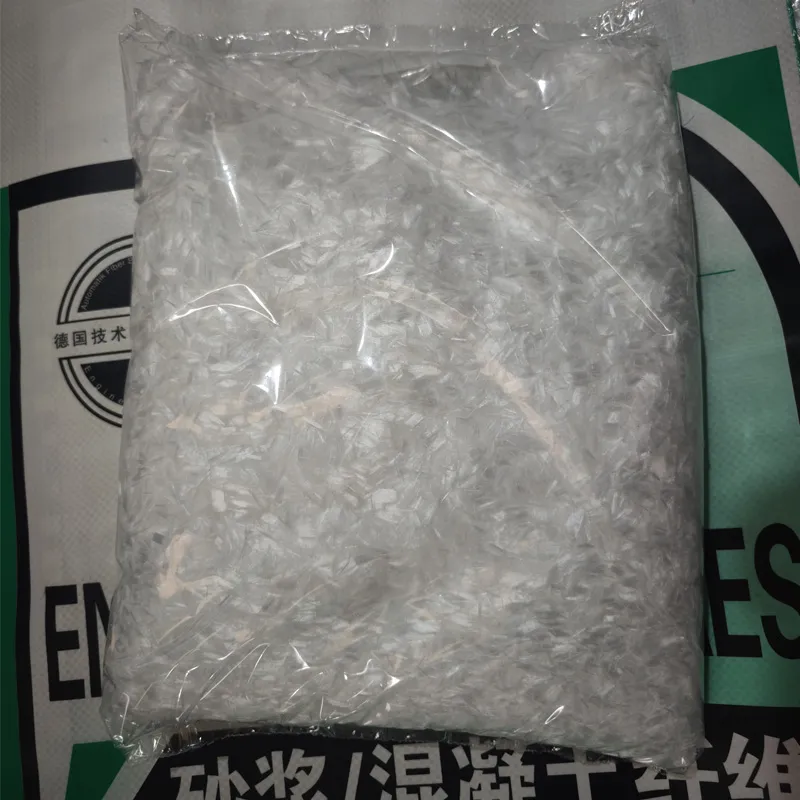

In contemporary engineering and construction, the integration of advanced materials is paramount for enhancing structural integrity and durability. Among these, Polypropylene Fiber stands out as a versatile and high-performance additive, fundamentally transforming the properties of cementitious composites. This synthetic macro or micro-fiber, derived from polypropylene polymer, is celebrated for its excellent chemical inertness, high tensile strength-to-weight ratio, and hydrophobic nature. Its primary function is to mitigate plastic shrinkage cracking in concrete, mortar, and other cement-based materials, thereby significantly improving their long-term performance and service life. The intrinsic characteristics of polypropylene, such as its low thermal conductivity and resistance to acids, alkalis, and salts, contribute to a robust solution for environments where chemical attack and temperature fluctuations are concerns. As a leading material for reinforcing various construction applications, from industrial flooring and precast concrete elements to shotcrete and rendered finishes, Polypropylene Fiber provides a cost-effective and efficient method to enhance crack control, impact resistance, and overall structural resilience. The demand for such advanced materials is continuously expanding, driven by the global imperative for sustainable, long-lasting, and resilient infrastructure. This segment will delve into the profound impact of this material on modern construction methodologies, exploring its unique properties and the broad spectrum of its applications across various industries, emphasizing its role in achieving superior engineering outcomes and extending the operational lifespan of structures.

The Advanced Manufacturing Process of Polypropylene Fiber

The production of high-quality Polypropylene Fiber is a sophisticated industrial process, meticulously controlled to ensure consistent product performance and adherence to stringent international standards. The journey begins with high-grade polypropylene resin pellets, which are fed into an extruder. Inside the extruder, the pellets are heated to their melting point and then forced through a spinneret – a die with numerous fine holes – forming continuous filaments. This initial extrusion process is critical for defining the basic structure and uniformity of the fibers. Following extrusion, these nascent filaments undergo a crucial drawing or stretching process. Drawing involves elongating the fibers, which aligns the polymer molecules along the fiber axis, thereby significantly increasing their tensile strength and modulus of elasticity, while reducing their diameter to the desired denier (a measure of linear mass density). This molecular orientation is key to the fiber's mechanical properties. After drawing, the continuous filaments are typically cut into specific lengths, ranging from micro-fibers (e.g., 6mm, 12mm) to macro-fibers (e.g., 50mm, 60mm), depending on their intended application. Throughout this entire manufacturing cycle, rigorous quality control measures are implemented. These include monitoring melt flow rate, fiber diameter consistency, tensile strength, and hydrophobic properties. Adherence to standards such as ISO 9001 ensures that each batch of Polypropylene Fiber meets precise specifications, guaranteeing predictable performance in diverse applications and maintaining the highest levels of product integrity and reliability.

Key Technical Parameters and Performance Metrics of Polypropylene Fiber

Understanding the technical parameters of Polypropylene Fiber is essential for its optimal application in various engineering contexts. These fibers are characterized by a range of properties that directly influence their performance in cementitious matrices. Typical lengths available range from 3mm to 60mm, with shorter fibers primarily used for plastic shrinkage crack control in thin sections and renders, while longer, often macro-synthetic fibers, provide post-crack residual strength and enhanced toughness for structural applications. Fiber diameter, or denier, also plays a crucial role; micro-fibers (e.g., 15-40 microns) offer extensive surface area for superior crack control at a microscopic level, whereas macro-fibers (e.g., 200-1000 microns) provide more substantial reinforcement. The tensile strength of Polypropylene Fiber typically falls within the range of 300-600 MPa, a critical factor for resisting tensile stresses within the concrete. Its low specific gravity (around 0.91 g/cm³) ensures excellent dispersion within the mix without settling. The melting point of approximately 160-170°C, combined with a high softening point, ensures stability under normal ambient conditions and during concrete hydration, though it limits applications in extremely high-temperature environments. Furthermore, Polypropylene Fiber exhibits excellent resistance to alkalis, acids, and salts, making it highly durable in harsh chemical environments, such as those found in industrial floors or wastewater treatment facilities. These combined properties ensure that the fiber effectively reduces the propensity for plastic cracking, improves impact resistance, and enhances the overall ductility and fatigue resistance of the composite material, leading to extended service life and reduced maintenance requirements.

| Parameter | Typical Value / Range | ASTM/ISO Standard |

|---|---|---|

| Material Composition | 100% Virgin Polypropylene | ASTM D1505 |

| Fiber Length | 3mm - 60mm (variable) | ASTM C1116 |

| Fiber Diameter (Denier) | 15-1000 microns (variable) | ASTM D1577 |

| Tensile Strength | 300 - 600 MPa | ASTM D3822 |

| Specific Gravity | 0.91 g/cm³ | ASTM D792 |

| Melting Point | 160 - 170°C | ASTM D3418 |

| Alkali Resistance | Excellent (no degradation) | ASTM C1116 |

Versatile Applications and Unparalleled Advantages of Polypropylene Fiber

The widespread adoption of Polypropylene Fiber across numerous sectors underscores its remarkable versatility and the significant advantages it brings to construction and beyond. In civil engineering, it is extensively used in concrete slabs-on-grade for industrial floors, airport pavements, and bridge decks, where its ability to reduce plastic shrinkage and settlement cracking is critical for long-term serviceability. For precast concrete elements, such as pipes, panels, and vaults, the incorporation of Polypropylene Fiber enhances impact resistance during handling and transportation, while also contributing to improved freeze-thaw durability. In shotcrete applications for tunnel linings, slope stabilization, and mining, these fibers help to prevent rebound and improve adhesion, leading to a more uniform and robust spray application. Beyond traditional concrete, Polypropylene Fiber is also vital in mortar and plaster mixes, preventing micro-cracking and improving surface integrity and abrasion resistance in renders and screeds. The primary technical advantage is its unparalleled efficiency in controlling plastic shrinkage cracking – a common issue in freshly placed concrete where rapid evaporation of bleed water leads to volumetric changes and surface cracks. The thousands of individual fibers create a dense, three-dimensional network within the concrete matrix, effectively bridging the tiny cracks as they form, thereby preventing their propagation into larger, more damaging fissures. This micro-reinforcement mechanism not only enhances the crack resistance but also contributes to improved impact and abrasion resistance, making surfaces more resilient to daily wear and tear. Furthermore, the inherent chemical inertness of polypropylene ensures that the fibers do not corrode or degrade within the alkaline concrete environment, guaranteeing long-term durability and structural integrity, significantly extending the service life of the finished product and reducing the need for costly maintenance.

Choosing the Right Supplier: Manufacturer Comparison and Customization Solutions

Selecting the right manufacturer for Polypropylene Fiber is a critical decision for procurement managers and engineers, as it directly impacts project success and material performance. A key differentiator among suppliers lies in their commitment to quality consistency, backed by international certifications such as ISO 9001, ensuring reliable product specifications across batches. Reputable manufacturers invest heavily in research and development, constantly refining fiber properties, and optimizing dispersion characteristics within concrete. They offer a diverse portfolio of fiber types, including monofilament, multifilament, and fibrillated options, each tailored for specific performance requirements and application dosages. Beyond standard products, leading suppliers excel in providing comprehensive customization solutions. This includes tailoring fiber length and denier to match unique project specifications, such as varying concrete mix designs, specific environmental exposures, or particular structural demands. For instance, a project requiring enhanced ductility for seismic resistance might necessitate a different fiber geometry and dosage than one primarily focused on reducing surface cracking in a standard slab. Furthermore, customized packaging options, from bulk bags for large-scale operations to smaller, dissolvable bags for ease of on-site mixing, demonstrate a manufacturer's flexibility and understanding of client operational needs. When evaluating potential partners, consider their technical support capabilities, including assistance with dosage rates, mixing procedures, and performance validation through laboratory testing. A robust after-sales service and a transparent warranty policy further solidify trust and ensure long-term, successful collaborations, demonstrating a manufacturer’s dedication to not just product delivery but holistic client support throughout the project lifecycle.

Real-World Impact: Application Cases and Trustworthiness in Supply

The tangible benefits of Polypropylene Fiber are best illustrated through its successful application in diverse real-world scenarios. For example, in large-scale industrial flooring projects, the integration of Polypropylene Fiber has demonstrably reduced the incidence of plastic shrinkage cracks by up to 90%, leading to flatter, more durable surfaces that require minimal maintenance over decades of heavy forklift traffic. In coastal infrastructure, such as marine jetties and breakwaters, the enhanced resistance to chloride ingress and freeze-thaw cycles provided by these fibers has significantly extended the service life of concrete structures exposed to aggressive saltwater environments. Tunnel linings reinforced with Polypropylene Fiber have exhibited superior toughness and post-crack ductility, maintaining structural integrity even under high stress, a testament to the fiber's ability to create a tenacious internal matrix. Our extensive service history, spanning over 15 years in the specialized chemical and construction materials industry, highlights our commitment to delivering high-performance products. We maintain ISO 9001:2015 certification for our manufacturing processes, ensuring that every batch of Polypropylene Fiber adheres to the highest global quality benchmarks. Our in-house testing laboratory meticulously verifies all product specifications, from tensile strength and modulus to length and denier distribution, providing clients with comprehensive data reports. We pride ourselves on a transparent delivery cycle, typically ranging from 7-15 days for standard orders, with expedited options available for urgent requirements, ensuring project timelines are met. Furthermore, our products are backed by a comprehensive quality warranty, reflecting our confidence in their performance. Our dedicated technical support team provides prompt assistance, from initial consultation on dosage and mixing to troubleshooting on-site challenges, ensuring our clients achieve optimal results and fostering long-term, trust-based partnerships.

Frequently Asked Questions (FAQs) about Polypropylene Fiber

-

What is the recommended dosage rate for Polypropylene Fiber in concrete?

The optimal dosage rate for Polypropylene Fiber largely depends on the specific application and desired performance. For general plastic shrinkage crack control in concrete slabs and screeds, typical dosages range from 0.6 kg/m³ to 0.9 kg/m³ (approx. 1.0 to 1.5 lbs/yd³). For enhanced toughness, impact resistance, or in structural applications where macro-synthetic fibers are used, dosages can range significantly higher, often from 3 kg/m³ to 9 kg/m³ or more. It is always recommended to consult with our technical specialists or refer to project-specific engineering specifications to determine the precise and most effective dosage for your application to ensure maximum benefits and compliance with relevant standards.

-

How does Polypropylene Fiber affect the workability of concrete?

When properly dispersed, Polypropylene Fiber generally has a minimal impact on the workability of fresh concrete. High-quality fibers are designed for ease of mixing and dispersion, preventing balling or clumping within the mix. While a slight reduction in slump might be observed with higher dosages due to the physical presence of the fibers, this can typically be compensated for by minor adjustments to the mix design, such as using an appropriate superplasticizer, without increasing the water-cement ratio. Proper mixing procedures, ensuring adequate mixing time, are crucial for achieving uniform fiber distribution throughout the concrete matrix, which is essential for realizing the full performance benefits of the fibers.

-

Can Polypropylene Fiber replace steel reinforcement or mesh?

It is crucial to understand that Polypropylene Fiber (especially micro-fibers) is primarily used for plastic shrinkage crack control and improving the durability and toughness of concrete, rather than for structural load-bearing reinforcement in the same manner as steel rebar or welded wire mesh. While macro-synthetic Polypropylene Fiber can provide significant post-crack residual strength and, in certain non-structural or lightly loaded applications, may partially replace some traditional steel reinforcement for crack control, it cannot fully replace structural steel reinforcement designed to carry significant tensile loads. Engineers must perform specific calculations and adhere to relevant building codes to determine if and where fiber reinforcement can supplement or, in limited cases, replace conventional reinforcement. It is a complementary material that enhances concrete's performance.

-

What is the shelf life and proper storage of Polypropylene Fiber?

Polypropylene Fiber typically has an indefinite shelf life when stored correctly, as it is chemically stable and resistant to biological degradation. However, to maintain its optimal performance characteristics, it should be stored in a cool, dry place, away from direct sunlight, extreme temperatures, and moisture. Polypropylene is susceptible to UV degradation over prolonged periods, so keeping it in its original packaging or in opaque, sealed container111s is essential. Proper storage ensures that the fibers remain free-flowing and easily dispersible, preventing clumping and maintaining their integrity for effective use in concrete mixes. Always check the manufacturer's recommendations for specific storage conditions and any recommended "use by" dates if provided.

Authoritative References

- ACI Committee 544. (2008). State-of-the-Art Report on Fiber Reinforced Concrete (ACI 544.1R-08). American Concrete Institute.

- Bentur, A., & Mindess, S. (2007). Fibre Reinforced Cementitious Composites. CRC Press.

- Naaman, A. E. (2007). High Performance Fiber Reinforced Cement Composites (HPFRCC). RILEM Publications.

- ASTM International. (Latest Editions). Standards for Fiber Reinforced Concrete (e.g., ASTM C1116).

Pervious