Company Profile

Website: https://www.yaguanhpmc.com

Contact:

- Phone: +86 16631151771

- Mobile: +86 18932532363

- Email: info@ya-guan.com

- Address: Room 1320, Block C, Dongsheng Plaza, Chang'an District, Shijiazhuang, Hebei Province

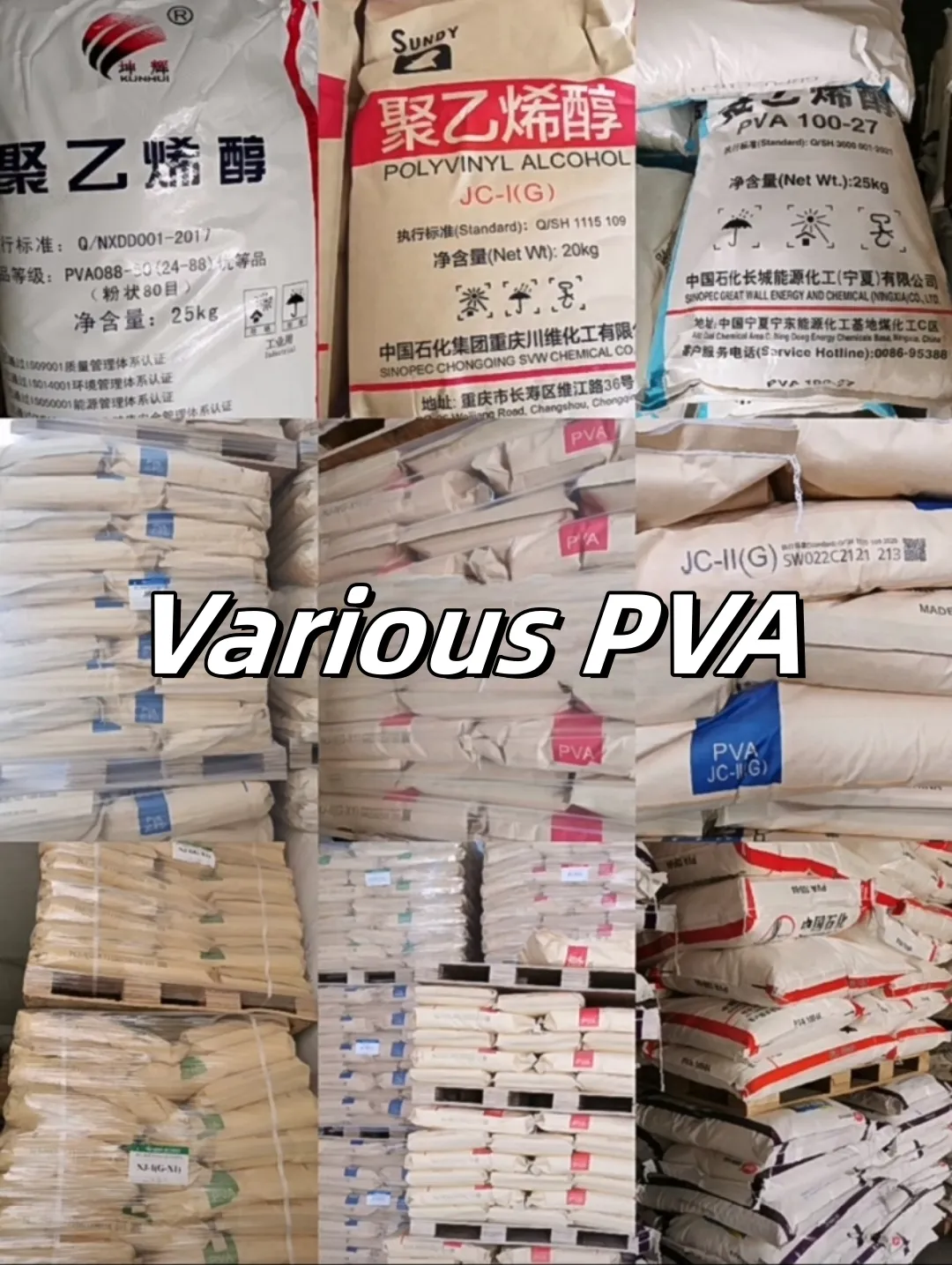

Polyvinyl Alcohol (PVA): Product Overview

CAS No.: 9002-89-5

Appearance: White flake, flocculent, or powdered solid; odorless.

Solubility: Easily soluble in water, but insoluble in gasoline, kerosene, vegetable oil, benzene, toluene, dichloroethane, carbon tetrachloride, acetone, ethyl acetate, methanol, ethylene glycol; slightly soluble in dimethyl sulfoxide.

Applications: Manufacturing of polyvinyl acetals, gas-resistant pipes, vinylon synthetic fibers, fabric treatment agents, emulsifiers, paper coatings, adhesives, glues, and more.

Product Page: https://www.yaguanhpmc.com/pva.html

Industry Trends: Polyvinyl Alcohol (PVA) Market Dynamics

Technical Parameters: Polyvinyl Alcohol (PVA)

| Parameter | Value / Range | Unit | Significance |

|---|---|---|---|

| Degree of Polymerization (DP) | 500-3500 | - | Polymer chain length, affects viscosity & strength |

| Hydrolysis Degree | 87–99+ | % | Water solubility and adhesive property |

| Viscosity (4% aq., 20°C) | 3–60 | mPa·s | Reflects chain length & solution behavior |

| pH (1% solution) | 5–7 | - | Chemical stability |

| Water Content | ≤ 5 | % | Stability in storage and process |

| Ash Content | < 0.7 | % | Purity and quality standard |

| Appearance | White flake or powder | - | Quality assurance |

Applications of Polyvinyl Alcohol (PVA)

- Textile Industry: Used as sizing agents for warp yarn, enhancing strength and abrasion resistance.

- PVA Films: Packaging of agricultural chemicals and detergents with water-soluble films (ResearchGate).

- Paper & Coatings: Application in paper coatings improves printability and oil resistance.

- Construction: Used as an additive for cement and mortar to enhance flexibility, durability, and bonding.

- Adhesives & Binders: Base for glue formulas due to strong cohesion and non-toxicity.

- Synthetic Fibers: Essential in the manufacture of vinylon (PVA fiber), widely used for reinforcement.

- Medical & Packaging: Biodegradable medical hydrogels, contact lenses, and eco-packaging.

Polyvinyl Alcohol (PVA) FAQ: Technical FAQ

-

Q1: What is the primary material composition of Polyvinyl Alcohol (PVA)?

A: Polyvinyl Alcohol (PVA) is a synthetic polymer derived through the polymerization of vinyl acetate, followed by partial or full hydrolysis, resulting in white flakes or powder. (See reference) -

Q2: What are the standard grades and specifications for Polyvinyl Alcohol (PVA)?

A: PVA is categorized by degree of polymerization (500–3500) and degree of hydrolysis (87–99+%), each grade suited for specific applications like films, adhesives, and fiber manufacturing. -

Q3: What is the typical installation standard or protocol for PVA usage in construction?

A: In construction, PVA is mixed with cement mortar or plaster under standardized dosages (typically 0.1–0.5% by mass), ensuring enhanced bonding and flexibility according to ASTM C1059 (ASTM International). -

Q4: What is the significance of the Hydrolysis Degree in Polyvinyl Alcohol?

A: The degree of hydrolysis determines the water solubility and chemical reactivity. Fully hydrolyzed PVA is less soluble at room temperature but offers greater tensile strength, while partially hydrolyzed grades dissolve quickly. -

Q5: What technical standards should be followed for PVA in adhesives?

A: Adhesive-grade PVA should comply with ISO 14021:2016 & GB/T 12010 standards, emphasizing purity, viscosity, and degree of polymerization. -

Q6: What parameters affect PVA’s performance in textile sizing?

A: Parameters include molecular weight, viscosity in solution, and residual acetyl content—directly impacting film formation, thread protection, and washing-out behavior. -

Q7: How is PVA environmentally friendly?

A: PVA is water-soluble, non-toxic, and biodegradable under appropriate conditions, making it a suitable replacement for petrochemicals in green applications (ACS Applied Polymer Materials).

Why Choose Shijiazhuang Yaguan New Material Technology Co., Ltd. for Polyvinyl Alcohol (PVA)?

- Strict quality assurance and advanced production lines ensure consistent Polyvinyl Alcohol (PVA) quality.

- Comprehensive product customization for diverse industrial applications.

- Strong R&D capability and technical support based on industry best practices and international standards.

- Responsive supply chain and excellent after-sales service for global clients.

- Certified compliance with ISO 9001, ISO 14001, and product-specific regulations.

- Phone: +86 16631151771

- Mobile: +86 18932532363

- Email: info@ya-guan.com

- Website: https://www.yaguanhpmc.com/pva.html

- Address: Room 1320, Block C, Dongsheng Plaza, Chang'an District, Shijiazhuang, Hebei Province

References & Industry Citations

2. ASTMD, “Standard Specification for Latex Agents for Bonding Fresh To Hardened Concrete”

3. ResearchGate, “Water Soluble Films-Based on Polyvinyl Alcohol”

4. ACS Publications, “Biodegradable Polyvinyl Alcohol Materials”

5. MarketsandMarkets, “Polyvinyl Alcohol Market 2024”

Pervious