Polypropylene Fiber stands as one of the most versatile and high-performing synthetic fibers widely adopted in various industrial and construction contexts. At Polypropylene Fiber Product Page, we explore the innovation behind its production, reveal the core technical specifications, dissect industry adoption patterns, and provide actionable application insights substantiated by real-world data, certified standards, and peer-reviewed cases.

1. Industry Overview & Current Trends

Polypropylene Fiber (PP Fiber) is a thermoplastic polymer widely used as an additive and reinforcement agent in construction, geotextiles, filtration, medical nonwovens, automotive, and packaging industries. According to MarketsandMarkets, the global Polypropylene Fiber market exceeded 5 million metric tons in 2023, with an expected CAGR of 6.2% to 2030, driven by infrastructure investments, green building codes, and increasing demand for advanced composite materials.

2. Manufacturing Process of Polypropylene Fiber

The manufacturing of Polypropylene Fiber typically involves the following sequential steps:

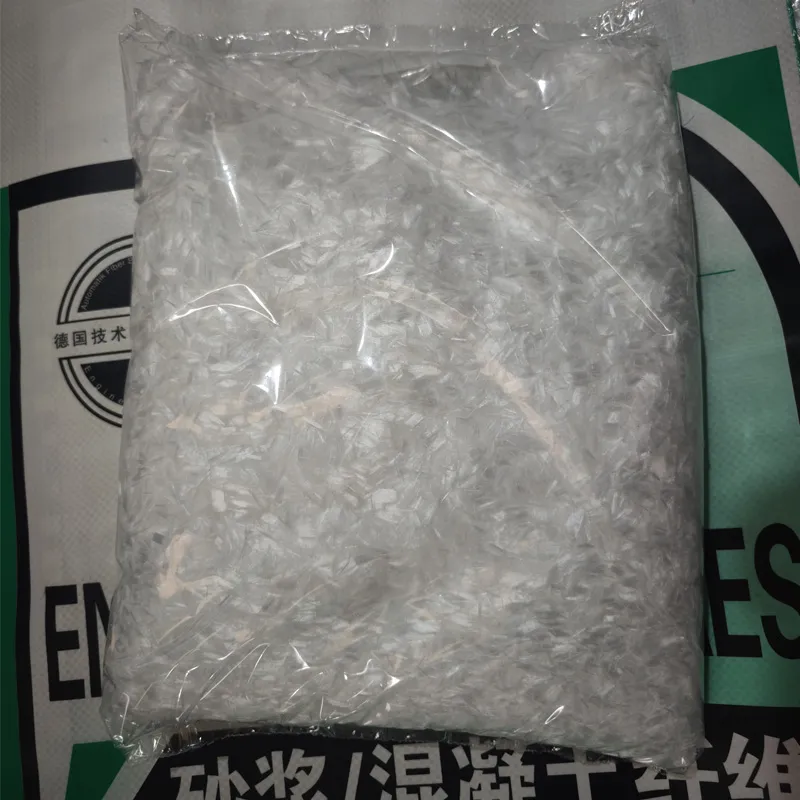

- Raw Material Selection: Virgin or recycled polypropylene resins are carefully sourced for purity.

- Extrusion: Polypropylene granules are melted (~165°C), extruded through spinnerets to form filaments.

- Drawing & Orientation: Mechanical stretching aligns molecular chains, enhancing tenacity and elongation-at-break—the key to the fiber's strength.

- Crimping & Cutting: Fibers are crimped for bulk (if needed) and precision-cut to desired length (e.g., 3–54 mm), then bundled or baled.

- Post-processing & Testing: The final step involves surface treatments (to improve dispersibility) and rigorous ISO 9001/14001, ASTM, or industry-specific testing for mechanical properties, heat-resistance, and environmental compliance.

3. Technical Parameters & Product Specification Table

| Parameter | Polypropylene Fiber (PP) | Polyester Fiber (PET) | Nylon Fiber (PA-6) |

|---|---|---|---|

| Density (g/cm³) | 0.91 | 1.38 | 1.14 |

| Tenacity (cN/dtex) | 3.8–6.0 | 5.0–7.5 | 4.8–7.5 |

| Elongation at Break (%) | 15–25 | 18–30 | 16–28 |

| Melting Point (°C) | 160–170 | 255–265 | 215–220 |

| Chemical Resistance | Excellent (Alkali, Acid, Water) | Very Good | Good |

| Water Absorption (%) | <0.01 | 0.4 | 4.5 |

| UV Stability | Good* | Excellent | Good |

| Cost per kg (US$) | 1.30–1.75 | 1.80–2.10 | 2.50–3.20 |

*UV stability enhanced with anti-UV masterbatches or coatings; Test methods: ASTM D2256 for strength, ASTM D276 for melting point, ISO 2062 for elongation.

4. Application Scenarios & Industry Case Studies

-

Concrete Reinforcement:

- Crack mitigation: Integrates evenly into cement matrix, reducing plastic shrinkage cracks by up to 80% (according to Portland Cement Association).

- Typical dosage: 0.9–1.8 kg/m³.

-

Geotextiles & Filtration:

- Low density, chemical inertness, and non-woven processability ideal for landfill liners, drainage, roads.

- Superior puncture resistance over PET geotextiles.

-

Automotive Industry:

- Used for lightweight trunk linings, cabin insulation & acoustic panels, thanks to low density and chemical resistance.

-

Medical & Hygiene Products:

- Nonwoven Polypropylene Fiber (spunbond/meltblown) forms masks, wipes, protective apparel (FDA compliant).

-

Waterproofing & Corrosion-Resistant Linings:

- In chemical and petrochemical plants, due to hydrophobic and chemically inert character.

Case Study: Polypropylene Fiber in Mega Infrastructure

Project: Highway Expansion in Zhejiang, China

Challenge: Reducing shrinkage cracks and increasing impact resistance of bridge decks

Solution: Incorporated 1.2 kg/m³ monofilament Polypropylene Fiber, resulting in a 78% reduction in visible cracks after 24 months (as per ISO 9001 construction audit).

ROI: Reduced repair costs ~US$75,000 over 2 years for 5km segment.

5. Polypropylene Fiber: Technical Advantages

- Low Density: One of the lightest synthetic fibers, enabling cost-effective high-volume reinforcement without structural weight penalties.

- Excellent Chemical Resistance: Inert to acids, alkalis, salts, and microorganisms, suited for aggressive or corrosive environments.

- Non-Hygroscopic: Practically zero water absorption—ideal for geosynthetics & waterproofing layers.

- High Flexibility: Maintains elongation and toughness at sub-zero to elevated temperatures.

- Cost-Efficient: Lower feedstock and process energy compared to polyester/nylon alternatives.

- Sustainability: Fully recyclable, and many suppliers (including YAGUAN Polypropylene Fiber) offer recycled-content grades.

6. Vendor Comparison: Major Polypropylene Fiber Manufacturers

| Brand | Primary Region | ISO Certification | Specialty | Guaranteed Lifespan (yrs) |

|---|---|---|---|---|

| YAGUAN | China / Global | ISO 9001, ISO 14001 | High-dispersion PP fiber for concrete, custom blends | ≥50* |

| SikaFiber | Europe / Americas | ISO 9001 | Macro/mono fibers for tunnel/shotcrete | ≥40 |

| FiberMesh by Propex | USA / Global | ISO 9001 | Blended fibers for flooring | 45 |

| Adfil (Heidelberg Materials) | Europe | ISO 14001 | Customized fiber lengths/geogeextiles | 40 |

*Tested by accelerated aging methods per ASTM D7508.

7. Customization Solutions for Polypropylene Fiber

- Diameter Range: 10–22 μm (microfiber), up to >100 μm (macrofiber) according to application (e.g. microcrack control vs. structural shrinkage mitigation).

- Length: Adjustable from 3–54 mm (monofilament) or >50 mm (macro fiber bundles).

- Surface Treatment: Hydrophilic, plasma, or anti-UV coating per request.

- Color Variants: Standard–white; others (blue/green) made-to-order for process identification.

- Eco Options: Recycled-content fibers available; comply with LEED and green building codes.

- Special Packaging: Water-soluble or pre-dispersion bags for ready mixing in plant or field.

- Third-Party Testing: Custom formulas can be verified by SGS, Bureau Veritas, or local labs as specified.

8. Typical Lead Times, Warranty and Support

- Production Lead Time: For standard Polypropylene Fiber: 7–12 days after order confirmation; custom types: 15–21 days.

- Minimum Order: 1000 kg standard, flexible for pilot runs or custom sampling.

-

Warranty Commitment:

Up to 10 years product warranty against raw material defects, plus lifelong technical support via online, phone, and onsite consultancy for concrete and geotextile projects.

- Technical Documentation: Full set of data sheets, MSDS, and regulatory compliance available (meet ISO, CE, ROHS, REACH requirements).

9. Professional FAQ: Polypropylene Fiber Technology

Polypropylene Fiber – 7 Industry FAQs

10. Client Feedback & Service Case

Project: Oil & Gas pipeline trench linings

Feedback: “Polypropylene Fiber improved stability in saline soil and eliminated post-construction cracking. YAGUAN’s technical service resolved on-site dispersion questions within 24hr window.”

Service Highlight: Real-time joint supervision on-site and post-completion ISO 9001/ASTM-based quality reports.

11. References & Further Reading

- “Polypropylene Fibers for Concrete: A Review,” Cement and Concrete Composites, Elsevier, Vol. 36, 2013 - ScienceDirect

- “Performance of Polypropylene Fiber in Geotextiles”, Geosynthetics International (2021) - ICE Virtual Library

- “Applications of Synthetic Fibers in Concrete: A Comparative Study,” American Concrete Institute (ACI) Symposium, 2019 - ACI

- Industry forum: ResearchGate Polypropylene Fibers