1. Industry Overview & Trends (2023-2028)

Redispersible Polymer Powder(RDP) is a water-soluble polymeric material produced through spray-drying, essential for enhancing flexibility, adhesion, and durability in construction and industrial formulations. Its adoption has surged, especially amidst the global shift to low-carbon construction and high-performance composite materials.

- Market Size (2023): Estimated at $2.1 billion globally (Grand View Research).

- CAGR 2024-2028: ~5.9% driven by Asian-Pacific & Middle Eastern infrastructure, green buildings, and high-performance cementitious products.

- Key Demand Drivers: Energy-efficient construction, prefabricated systems, water-resistant flooring, EIFS/ETICS, tile adhesives, external renders.

2. What is Redispersible Polymer Powder(RDP)? — Definition & Core Value

Redispersible Polymer Powder(RDP) is a free-flowing, white/off-white powder produced mainly from vinyl acetate–ethylene (VAE) or vinyl acetate–vinyl versatate (VA/VeoVa). It is redispersed rapidly in water to form stable emulsions, imparting crucial properties such as:

- Improved Flexural Strength: Resists cracking in mortars/renders.

- Enhanced Adhesion: Exceptional bonding to diverse substrates (concrete, masonry, insulation boards).

- Water Repellency & Durability: Reduces water absorption and efflorescence risk.

- Workability & Flexibility: Better flow, easier troweling, and greater freeze-thaw resistance.

3. Manufacturing Process: From Monomer to High-Performance RDP

The Redispersible Polymer Powder(RDP) manufacturing process combines advanced emulsion polymerization with state-of-the-art spray drying. Each stage is governed by ISO 9001/14001 and industry-specific standards. Below is a simplified flow chart:

(VAE, VA/VeoVa, styrene acrylic)

Manufacturing is traceable, and finished batches undergo rigorous QC (e.g., DSC, FTIR, viscosity, particle distribution) to meet international compliance and customer specifications.

4. Technical Parameters: RDP Data Sheet & Product Comparison

| Parameter | Unit | Typical Value | Test Method |

|---|---|---|---|

| Appearance | - | White free-flowing powder | Visual |

| Solids Content | % | 98.0 ± 1.0 | ISO 3251 |

| Particle Size (D50) | µm | 80~120 | ISO 13320 |

| Brookfield Viscosity (5% solution) | mPa.s | 300–1500 | Brookfield |

| pH Value (25°C, 10% dispersion) | - | 5–8 | ISO 976 |

| Minimum Film Formation Temp (MFFT) | °C | 2–5 | ISO 2115 |

| Redispersibility | Grade | >95% | EN 12004 |

| Protective Colloid | - | Polyvinyl alcohol (PVA) | - |

5. Data Visualization: RDP Properties, Performance & Market Comparison

6. Competitive Manufacturer Comparison (2024)

| Producer | Country | Flagship RDP | Certifications | Focus Segment |

|---|---|---|---|---|

| Wacker Chemie | Germany | VINNAPAS® | ISO 9001, ISO 14001 | EIFS, tile adhesives |

| Dow Construction | USA | DOW™ RDP Series | ISO 9001 | Self-levelers, concrete repair |

| Shandong Yaguan | China | YG-RDP | ISO 9001, SGS, CE | Mortar blends, dry-mix |

| Celanese | USA | MOWILITH® | ISO 9001 | Waterproofing, renders |

| Synthomer | UK | BINDER POWDER | ISO 9001, 14001 | Decorative plasters |

- Customizable formulation to climate, substrate, and end-use.

- Batch traceability, rapid technical support, short lead times (2-4 weeks worldwide).

- Backed by major certifications (ISO 9001/SGS) and referenced in EN 12004-compliant projects.

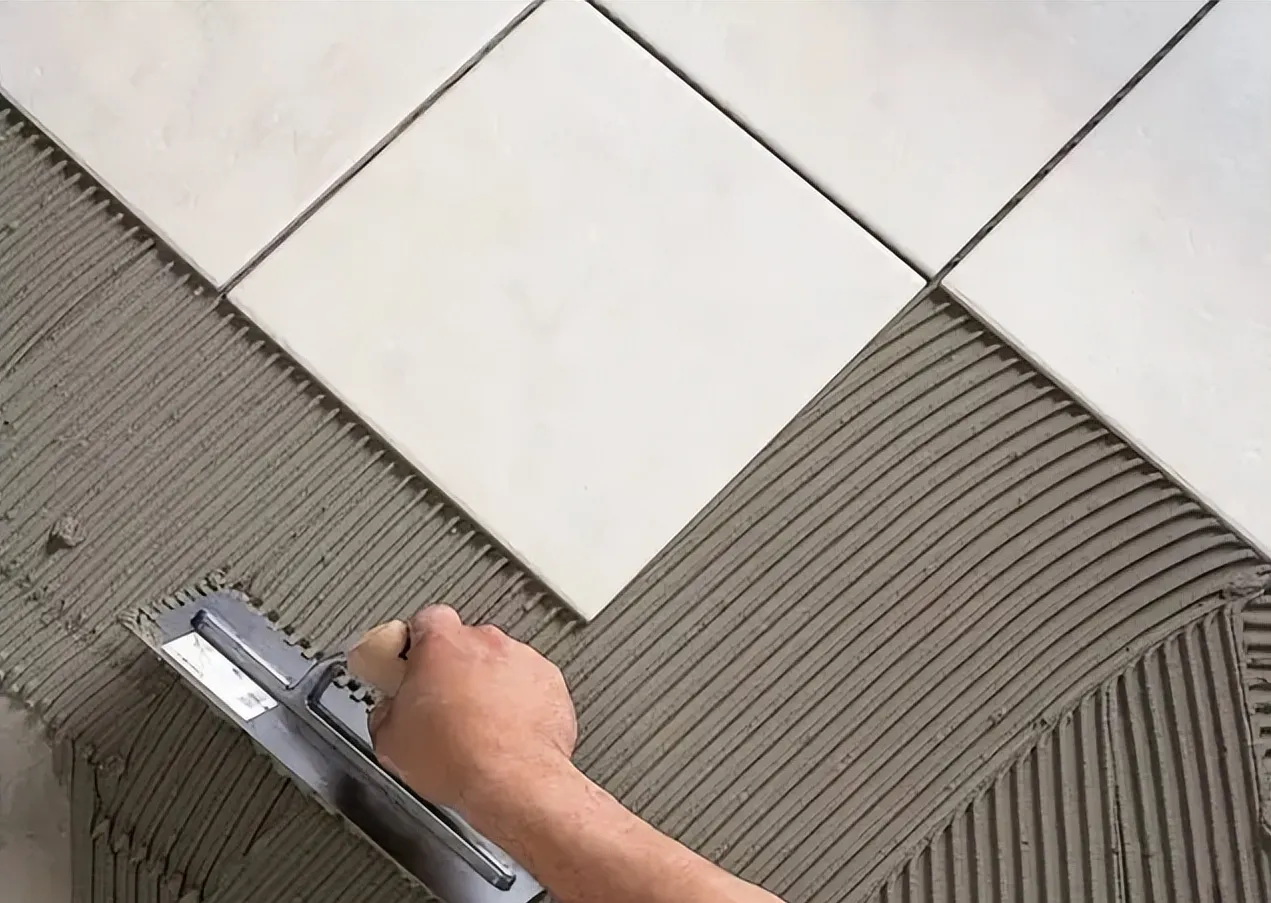

7. RDP in Action: Application Scenarios & Project Advantages

- Energy-efficient construction: EIFS, ETICS, insulation renders, wall putties.

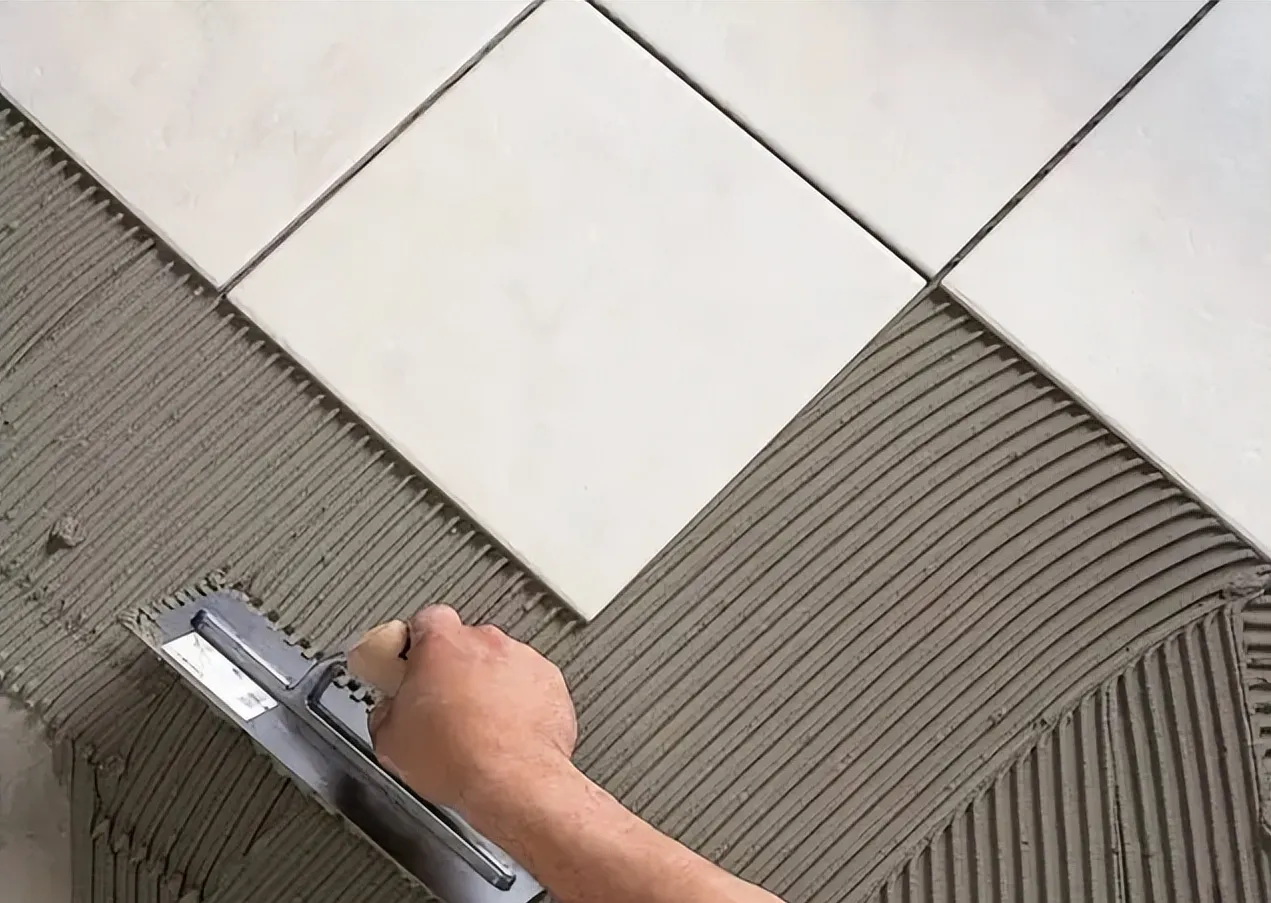

- High-flexibility adhesives: Tile fixing, thermal boards, decorative plasters.

- Self-leveling flooring: Improved tensile/flexural strength, rapid setting.

- Waterproofing & repair mortars: Enhanced crack resistance, hydrophobic effect.

Application of Redispersible Polymer Powder(RDP) in over 200,000 m2 EIFS systems.

- Energy savings: 18% reduction in heating/cooling loads due to efficient thermal insulation.

- Installation speed: Faster setting (25% reduction in construction cycle), minimized cracking.

Customized high-flexibility RDP-modified tile adhesive withstands heavy vibration, extreme summer-winter cycles, with negligible detachment or efflorescence after 3 years.

- Certified to EN 12004: Improved pull-off strength & thermal cycling tolerance.

- Confirmed by site testing and maintenance logs.

8. Custom Solutions & Engineering Support

Yaguan offers tailored Redispersible Polymer Powder(RDP) solutions:

- Climate-specific packages (anti-cracking for cold climates, anti-efflorescence for humid areas).

- Low-VOC, hypoallergenic grades for green building certifications like LEED, BREEAM.

- Technical consulting: Mix design optimization, on-site trouble-shooting, certification documents, and compatibility testing.

- Sample support within 7 days globally.

Contact our engineers for customized formulations or tender support.

9. Delivery, Warranty & Technical Service

- Standard Lead Time: 7-20 working days; expedited shipping available.

- Warranty: 24 months (unopened, dry storage <30°C).

- Batch QC: Every drum carries full test COA (solids content, ash, dispersibility by EN 12004).

- Support: 24h response, global application team for on-site or remote troubleshooting.

- Certifications: ISO 9001:2015, SGS, CE.

10. Professional FAQ: Redispersible Polymer Powder(RDP) Key Technical Terms

11. Customer Feedback & Project References

12. Industry Authority, Certifications, and Partnerships

- Products conform to ISO 9001:2015, ISO 14001, EN 12004, and RoHS standards.

- Long-term partnerships with TOP 10 global adhesives manufacturers (Wacker, Dow, Celanese), plus regional drymix leaders.

- Tested in external labs (SGS/TÜV/EUROFINS).

13. References & Further Reading

- [1] “Redispersible Polymer Powder Market Size, Share & Trends Analysis”, GrandViewResearch, 2023

- [2] “Technical Analysis and Application of RDP in Drymix Mortars”, Construction & Building Materials, 2023

- [3] Wacker Chemie AG – VINNAPAS® RDP Technical Data

- [4] Dow Construction Chemicals – Dow RDP Solutions for Construction

- [5] Industry forum discussions: drymix.info | RILEM

- [6] Product website: Yaguan Redispersible Polymer Powder(RDP)

Pervious