Calcium formate, a multifunctional organic salt, has become a highly valued additive across diverse industries due to its chemical stability, environmental safety, and outstanding performance characteristics. From enhancing concrete durability to improving livestock digestion and preserving feed, this compound and its related forms—such as calcium diformate, calcium formate accelerator, and derivatives based on calcium formate from formic acid—have earned a solid reputation. This article explores the chemistry, applications, and advantages of these materials, supported by insights into their regulatory identifiers like calcium formate CAS data.

Concrete Performance Enhancement in Cold Conditions

One of the most prominent applications of calcium formate is in the construction sector as a calcium formate accelerator. In cold environments, concrete can suffer from slow hydration and low early strength, which can jeopardize structural performance. Calcium formate helps resolve this issue by accelerating cement hydration, shortening the setting time, and enabling earlier demolding. This function is particularly important for precast concrete manufacturing, roadwork in low temperatures, and emergency repairs.

Unlike chloride-based accelerators, calcium formate is non-corrosive to steel reinforcements, making it ideal for long-term structural reliability. Moreover, it enhances frost resistance, which is critical for projects exposed to freeze-thaw cycles. Its incorporation into cementitious systems is simple, and its effects are measurable, providing both practical and economic benefits to construction teams working in variable climate conditions.

Livestock Health and Feed Preservation

In animal nutrition, calcium diformate has gained attention as a dual-function additive. It serves as both a source of calcium and a powerful acidifier that lowers the pH of the digestive tract, improving nutrient absorption and inhibiting pathogenic microorganisms such as E. coli and Salmonella. As an antimicrobial agent, calcium diformate contributes to gut health and feed hygiene, especially in swine and poultry production systems.

Additionally, its preservative qualities help extend the shelf life of feed materials in storage, reducing the risk of spoilage and loss. The feed industry appreciates calcium diformate for its high bioavailability, ease of mixing, and compatibility with other feed components. It reduces the need for synthetic growth promoters and antibiotics, supporting a shift toward more sustainable and residue-free livestock farming practices.

Chemical Identity and Production Method

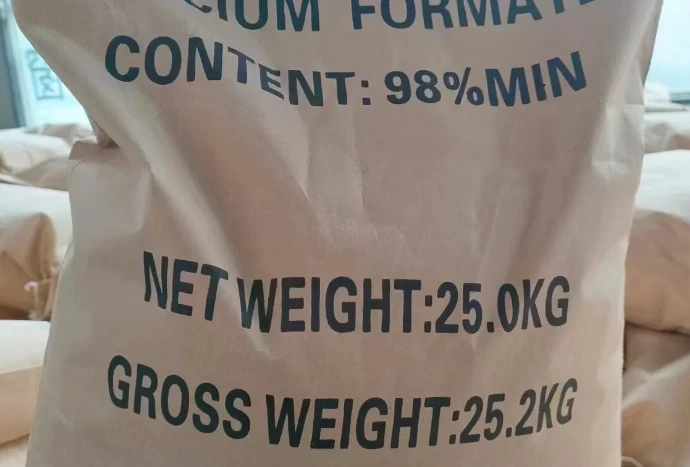

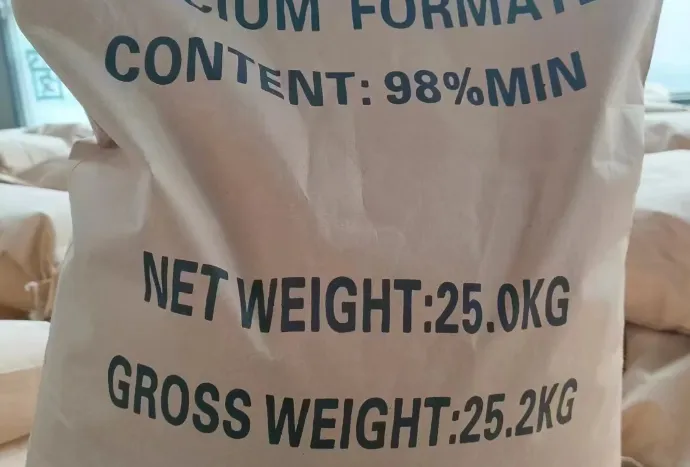

Calcium formate is chemically known as calcium methanoate and is typically produced through a neutralization reaction involving calcium formate from formic acid and calcium carbonate or calcium hydroxide. This straightforward synthesis yields a stable white crystalline powder that is water-soluble and easy to handle.

The material is commonly identified using its calcium formate CAS number: 544-17-2, which ensures accurate reference in chemical databases, import/export documentation, and quality assurance systems. The simplicity of its structure and the purity achievable through controlled manufacturing make calcium formate a reliable raw material for both technical-grade and food-grade applications.

Due to its consistent molecular characteristics, calcium formate is used not only in construction and feed but also in the leather, textile, and plastic industries. It acts as a buffering agent, tanning auxiliary, and PVC stabilizer. In all these sectors, its low toxicity and environmental compatibility offer a compelling advantage over more hazardous alternatives.

Applications in Oilfield and Industrial Systems

Oilfield operations also benefit from the inclusion of calcium formate in drilling fluids and well completion systems. Its high solubility and stability under pressure make it useful in formulating fluids that maintain consistent viscosity and chemical activity, even under extreme temperature and pH conditions. In well cementing, calcium formate enhances early strength gain and reduces the risk of cement failure during pressure changes.

Other industrial applications include use in de-icing agents, where calcium formate performs well as an eco-friendly substitute for urea and chloride salts. Its fast action, low corrosivity, and biodegradability make it particularly suitable for sensitive environments such as airports and urban infrastructure. Additionally, in leather tanning, it acts as a pH stabilizer and promotes uniform dye absorption. In plastics manufacturing, it serves as a heat stabilizer in PVC compounds, improving processing safety and final product durability.

Calcium Formate FAQs

What is calcium formate and how is it used in concrete?

Calcium formate is an organic salt that functions effectively as a calcium formate accelerator in concrete applications. It reduces the setting time of cement and promotes early strength development, especially in cold conditions. By enhancing hydration kinetics, it allows faster construction cycles and improved durability, while avoiding corrosion risks associated with chloride-based accelerators.

What are the differences between calcium formate and calcium diformate?

Calcium formate and calcium diformate differ slightly in their structure and application focus. While both are derivatives of formic acid, calcium formate is primarily used in concrete and industrial chemistry, whereas calcium diformate is optimized for feed applications due to its enhanced antimicrobial properties. The latter is particularly effective in improving animal gut health and feed preservation.

What is the CAS number for calcium formate and why does it matter?

The calcium formate CAS number is 544-17-2, a unique identifier assigned by the Chemical Abstracts Service. It helps manufacturers, suppliers, and regulatory bodies distinguish calcium formate from other compounds in technical documents, product labels, and compliance reports. This ensures precise tracking and proper usage across global supply chains.

How is calcium formate produced from formic acid?

Calcium formate from formic acid is produced by reacting formic acid with calcium hydroxide or calcium carbonate. This reaction forms calcium formate and water or carbon dioxide as by-products. The resulting product is then filtered, dried, and milled into a fine powder suitable for various applications, including construction, animal feed, and industrial additives.

Can calcium formate be used in oilfield and industrial processes?

Yes, calcium formate is employed in oilfield operations as a fluid stabilizer and cement accelerator. It helps maintain fluid consistency under high pressure and extreme pH conditions. Beyond oilfields, it is widely used in tanning, plastics, and de-icing products, thanks to its chemical stability, low toxicity, and compatibility with environmentally conscious industrial standards.

Pervious