Introduction to Polypropylene Fiber: An Engineered Material for Modern Applications

In the realm of advanced materials, Polypropylene Fiber stands out as a versatile and high-performance synthetic fiber. Derived from polypropylene polymer, a thermoplastic resin, these fibers are engineered to impart exceptional properties to a wide array of products and systems. Their unique molecular structure and manufacturing precision enable them to enhance durability, provide reinforcement, and offer superior resistance across diverse industrial sectors. From reinforcing concrete and asphalt to serving as critical components in filtration systems and geotextiles, the demand for high-quality Polypropylene Fiber is steadily growing, driven by global trends towards sustainable infrastructure, lightweight materials, and enhanced product longevity.

The market for Polypropylene Fiber is experiencing robust growth, propelled by increasing applications in construction, automotive, and nonwoven industries. Innovations in polymer science and fiber extrusion technologies are continuously expanding the performance envelope of these fibers, allowing for tailored solutions that meet highly specific technical requirements. As industries seek more efficient, durable, and cost-effective materials, Polypropylene Fiber is increasingly becoming the material of choice, demonstrating its critical role in modern engineering and manufacturing. Its ability to provide anti-cracking, anti-seepage, and wear-resistant properties, while often reducing overall material costs and improving construction efficiency, positions it as an indispensable component in many forward-looking projects.

This comprehensive article delves into the intricate world of Polypropylene Fiber, exploring its technical specifications, manufacturing processes, diverse applications, and inherent advantages. We will also address crucial considerations for B2B decision-makers, including manufacturer evaluation, customization options, and the critical importance of a robust supply chain and dedicated technical support, aligning with Google's principles for expertise, experience, authoritativeness, and trustworthiness.

The Science Behind Polypropylene Fiber: Technical Parameters and Properties

Understanding the efficacy of Polypropylene Fiber necessitates a deep dive into its intrinsic technical parameters and material properties. These characteristics are fundamental to its performance in various demanding applications, ensuring its reliability and longevity. The superior performance of Polypropylene Fiber originates from the excellent inherent properties of the polypropylene polymer itself, combined with precise control over fiber morphology during production.

Key Technical Specifications of Polypropylene Fiber

The performance of Polypropylene Fiber is quantified by several critical parameters. Manufacturers adhere to stringent international standards such as ISO and ASTM to ensure consistency and quality. Below is a typical range of technical specifications you might encounter for high-grade Polypropylene Fiber used in construction and industrial applications:

| Parameter | Typical Value Range | Unit/Description |

|---|---|---|

| Fiber Type | Monofilament, Fibrillated, Mesh | Geometric structure for specific applications |

| Material | 100% Virgin Polypropylene | Ensures purity and consistent performance |

| Denier (dtex) | 10 - 2000 (typical for monofilament); Higher for others | Weight in grams of 9,000 meters of fiber. Influences strength & flexibility. |

| Fiber Length | 3 mm - 100 mm (or custom cut) | Determined by application requirements (e.g., concrete reinforcement) |

| Specific Gravity | 0.90 - 0.91 | Lighter than water; ensures uniform dispersion in mixtures |

| Tensile Strength | 350 - 700 MPa (50-100 ksi) | Resistance to breaking under tension (ASTM D3822) |

| Elongation at Break | 15 - 30% | Ability to stretch before breaking. Provides toughness. (ASTM D3822) |

| Modulus of Elasticity | 3.5 - 6.0 GPa | Stiffness; resistance to elastic deformation |

| Melting Point | 160 - 170 °C | Thermal stability range |

| Acid & Alkali Resistance | Excellent | Unaffected by most common acids and alkalis |

| Water Absorption | Negligible (Hydrophobic) | Does not absorb moisture, preventing swelling and degradation |

Understanding Fiber Morphology and Performance

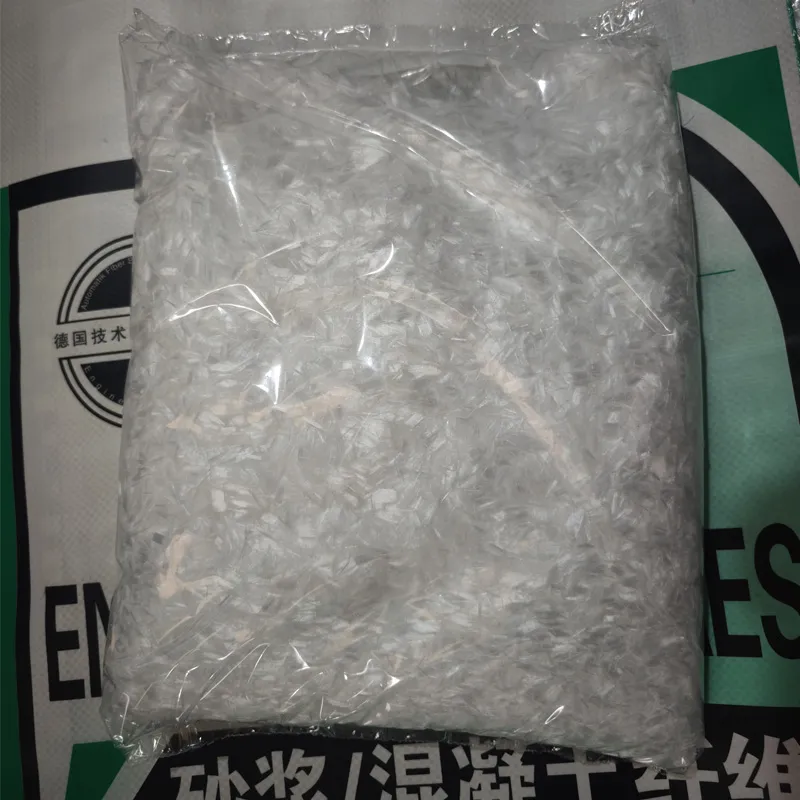

The morphology of Polypropylene Fiber plays a crucial role in its performance. Monofilament fibers are single, continuous strands, offering excellent dispersion and uniform reinforcement. Fibrillated fibers, on the other hand, are net-like structures that provide a larger surface area for mechanical bonding, especially beneficial in concrete to reduce plastic shrinkage cracking. Mesh fibers offer a more substantial three-dimensional reinforcement network.

The specific gravity of approximately 0.90-0.91 means Polypropylene Fiber is one of the lightest commercial fibers available, making it highly buoyant. This property is crucial in applications like concrete, where it ensures uniform dispersion without settling, thereby providing consistent crack control throughout the matrix. Its high tensile strength-to-weight ratio makes it an incredibly efficient reinforcing material. Furthermore, its excellent chemical inertness means it resists degradation from a wide range of chemicals, including acids, alkalis, and salts, which is vital in harsh industrial environments like petrochemical plants or wastewater treatment facilities. This inherent corrosion resistance significantly extends the lifespan of materials incorporating Polypropylene Fiber, reducing maintenance and replacement costs.

Manufacturing Excellence: The Polypropylene Fiber Production Process

The manufacturing of high-quality Polypropylene Fiber is a sophisticated process that demands precision engineering and rigorous quality control. It typically involves several key stages, beginning with the raw polymer and culminating in the finished fiber product, ready for diverse industrial applications. The typical process ensures consistent quality, optimized performance characteristics, and adherence to international standards like ISO 9001 for quality management systems.

Detailed Manufacturing Process Flow of Polypropylene Fiber

- Raw Material Preparation: The process begins with high-purity polypropylene resin pellets. These pellets are typically virgin polymer to ensure optimal performance characteristics. They are carefully selected based on their melt flow index, molecular weight distribution, and purity, as these factors directly impact the final fiber properties. The raw material is fed into an extruder.

- Melt Spinning (Extrusion): The polypropylene pellets are melted in a high-temperature extruder, forming a viscous polymer melt. This melt is then forced through a spinneret – a die with multiple fine holes. The shape and size of these holes determine the initial cross-section and diameter of the nascent fibers. As the molten polymer emerges from the spinneret, it enters a cooling chamber (usually an air quench system) where it solidifies into continuous filaments. This stage is critical for forming the basic structure of the fiber.

- Drawing and Stretching: The solidified filaments are then subjected to a drawing or stretching process. This involves passing the fibers over a series of heated rollers rotating at progressively increasing speeds. The drawing process aligns the polymer molecules along the fiber axis, dramatically increasing the fiber's tensile strength and modulus while reducing its elongation. This molecular orientation is key to achieving the desired mechanical properties of the final Polypropylene Fiber. The draw ratio can be adjusted to fine-tune the fiber's strength and elongation characteristics.

- Crimping and Cutting (for Staple Fiber): For staple fibers, which are cut into specific lengths, the drawn filaments may undergo crimping. Crimping introduces waves or bends into the fiber, enhancing bulk, resilience, and inter-fiber cohesion, which is particularly useful for nonwoven applications or for improving dispersion in cementitious mixtures. After crimping (or directly after drawing for some continuous filament applications), the fibers are cut to the desired length (e.g., 3mm, 6mm, 12mm, 19mm, 24mm, 48mm for concrete reinforcement) using precision cutters. Fibrillated fibers would undergo an additional step where the film is stretched and slit to create the net-like structure.

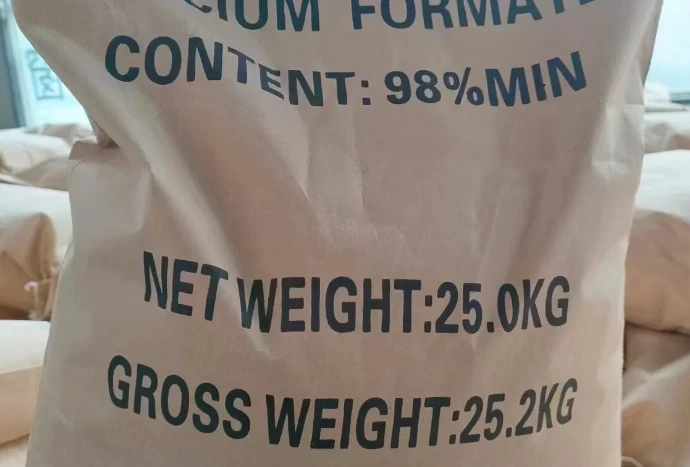

- Finishing and Packaging: The cut fibers are then treated with a finishing agent, which can include lubricants, anti-static agents, or adhesion promoters depending on the intended application. This finish aids in processing, prevents static buildup, and can improve bonding with other materials. Finally, the finished Polypropylene Fiber is dried, weighed, and packaged into bags, bales, or rolls, ready for distribution. Each batch undergoes rigorous quality checks to ensure compliance with specifications.

Throughout this process, stringent quality control measures are implemented. This includes testing the raw materials upon arrival, monitoring process parameters (temperatures, pressures, speeds), and conducting in-process and final product testing. Common tests performed on the finished Polypropylene Fiber include denier measurement, tensile strength and elongation testing (adhering to ASTM D3822/D3822M-14), specific gravity, melting point, and chemical resistance tests. Adherence to standards like ISO 9001 and ANSI ensures that the product meets or exceeds performance expectations, guaranteeing a service life of decades in suitable applications, such as concrete where it is protected from UV degradation.

The quality of the manufacturing process directly impacts the product's performance advantages. For instance, precise control over the drawing process ensures that the Polypropylene Fiber achieves optimal tensile strength and minimal elongation, critical for crack control in concrete. In applications like filtration, consistent denier and uniform fiber distribution are paramount for efficient particle capture.

Diverse Applications of Polypropylene Fiber Across Industries

The versatility and unique properties of Polypropylene Fiber have led to its widespread adoption across an impressive range of industries. Its ability to enhance material properties, coupled with its cost-effectiveness, makes it an attractive solution for engineers and manufacturers seeking improved performance and durability.

Construction and Infrastructure

One of the most significant application areas for Polypropylene Fiber is in the construction industry. When incorporated into concrete, mortar, or asphalt, it dramatically improves their mechanical properties and extends their service life.

- Concrete Reinforcement: Polypropylene Fiber is widely used as an additive in concrete to reduce plastic shrinkage cracking and improve post-crack residual strength. It acts as a secondary reinforcement, distributing stresses more evenly throughout the concrete matrix, thereby preventing micro-cracks from propagating into larger structural flaws. This is especially critical in applications such as industrial floors, precast elements, tunnel linings, and shotcrete, significantly improving durability and reducing maintenance costs. Its inclusion can lead to a more ductile concrete, absorbing energy better during seismic events or impacts.

- Asphalt Pavements: In asphalt mixtures, Polypropylene Fiber enhances resistance to rutting, fatigue cracking, and thermal cracking. It stabilizes the asphalt binder, increasing its viscosity and improving the overall mechanical stability of the pavement. This is particularly beneficial for high-traffic roads, airport runways, and industrial pavements, contributing to longer-lasting and more resilient infrastructure.

- Mortars and Renders: Similar to concrete, Polypropylene Fiber improves the crack resistance and workability of mortars and renders, leading to more durable finishes for buildings and facades. It reduces segregation and bleeding, resulting in a more uniform mix.

Filtration and Nonwovens

The excellent chemical resistance, low specific gravity, and hydrophobicity of Polypropylene Fiber make it an ideal material for filtration media and various nonwoven fabrics.

- Liquid and Air Filtration: Polypropylene Fiber is extensively used in filter cartridges, bags, and membranes for liquid filtration (e.g., water treatment, chemical processing) and air filtration (e.g., HVAC filters, industrial dust collection). Its chemical inertness ensures it does not degrade or contaminate the filtered medium, while its fine denier allows for efficient particle capture. This translates to lower operational costs due to extended filter life and reduced energy consumption for filtration systems.

- Geotextiles: In civil engineering, Polypropylene Fiber-based geotextiles are employed for separation, filtration, reinforcement, protection, and drainage applications in road construction, landfills, and erosion control projects. Their durability, resistance to biological degradation, and high tensile strength provide long-term stability to earthworks.

- Nonwoven Fabrics: Used in hygiene products (diapers, sanitary pads), medical textiles (surgical gowns, masks), automotive interiors, and agricultural covers due to its softness, breathability, and barrier properties.

Textiles and Industrial Fabrics

Beyond construction and filtration, Polypropylene Fiber finds its way into various textile and industrial fabric applications due to its strength, light weight, and chemical resistance.

- Ropes, Nets, and Webbing: Its buoyancy and strength make it ideal for marine ropes, fishing nets, and industrial webbing. Unlike natural fibers, Polypropylene Fiber does not absorb water, maintaining its strength and form in wet conditions.

- Automotive Components: Used in car interiors (carpets, upholstery), trunk linings, and battery separators due to its light weight, durability, and resistance to chemicals and mildew.

- Protective Clothing: Its chemical resistance and hydrophobic nature make it suitable for disposable protective wear in chemical handling environments.

In typical applications within the petrochemical, metallurgical, and water supply/drainage industries, Polypropylene Fiber offers distinct advantages such as exceptional corrosion resistance, superior chemical inertness against a broad spectrum of aggressive media, and the ability to significantly extend the operational lifespan of materials. For instance, in chemical storage tanks or piping systems, PP fiber-reinforced composites can withstand corrosive liquids that would quickly degrade traditional materials, leading to substantial energy savings by preventing leaks and reducing the need for frequent replacements. Its application often results in notable energy conservation through improved material efficiency and reduced maintenance downtime.

Unrivaled Advantages of Polypropylene Fiber

The widespread adoption of Polypropylene Fiber across critical industries is a testament to its compelling technical and economic advantages. These benefits position it as a superior alternative or enhancement to traditional materials.

- Superior Chemical Resistance: Polypropylene Fiber is highly resistant to a vast array of acids, alkalis, salts, and many organic solvents. This inertness prevents degradation and ensures long-term performance even in highly corrosive environments, unlike steel or other synthetic fibers that might succumb to chemical attack. This is a critical advantage in applications ranging from concrete exposed to de-icing salts to filtration systems handling aggressive chemicals.

- Excellent Hydrophobicity and Moisture Resistance: Polypropylene is inherently hydrophobic, meaning it does not absorb water. This property is crucial in applications where moisture absorption could lead to swelling, degradation, or a loss of mechanical properties. In concrete, for example, it prevents issues like freeze-thaw damage and ensures fibers remain uniformly dispersed without clumping. For filtration media, it facilitates efficient dewatering and prevents mold growth.

- High Tensile Strength-to-Weight Ratio: Despite being one of the lightest commercial fibers (specific gravity Polypropylene Fiber exhibits impressive tensile strength. This combination of lightness and strength makes it highly efficient for reinforcement purposes, providing significant performance benefits without adding undue weight to the final product.

- Enhanced Durability and Extended Service Life: When integrated into materials like concrete or nonwovens, Polypropylene Fiber dramatically enhances their resistance to cracking, abrasion, and impact. By acting as a micro-reinforcement, it mitigates stress concentrations and prevents the propagation of micro-cracks, leading to products with significantly longer operational lifespans and reduced maintenance requirements. This is a direct benefit for asset owners in industries such as civil infrastructure and industrial facilities, where long-term performance is paramount.

- Cost-Effectiveness and Efficiency: While offering premium performance, Polypropylene Fiber is often a cost-effective solution compared to traditional reinforcement methods or more expensive synthetic fibers. Its ease of dispersion and processing can also lead to efficiencies in manufacturing and construction, reducing labor and equipment costs. For example, in concrete, it can partially or fully replace welded wire mesh in certain applications, streamlining the construction process.

- Anti-Fibrillation and UV Stabilization: Modern Polypropylene Fiber can be engineered with specific additives to resist UV degradation for exterior applications or designed to prevent "fibrillation" (unwanted splitting of fibers) in applications where high shear forces are present, ensuring consistent performance.

- Thermal Insulation Properties: Polypropylene has low thermal conductivity, making Polypropylene Fiber useful in applications requiring insulation, such as certain textiles or building materials, contributing to energy efficiency.

These collective advantages make Polypropylene Fiber an indispensable material for engineers and manufacturers striving for optimized performance, increased product longevity, and reduced lifecycle costs across a broad spectrum of industrial and construction applications. Its ability to deliver robust performance in challenging environments underscores its value as an advanced engineered material.

Choosing Your Partner: Manufacturer Comparison and Custom Solutions

Selecting the right supplier for Polypropylene Fiber is as crucial as understanding the material itself. For B2B buyers and technical decision-makers, evaluating potential manufacturers involves looking beyond just price, focusing on critical factors that ensure product quality, supply chain reliability, and comprehensive support.

Key Selection Criteria for a Polypropylene Fiber Manufacturer

- Quality Certifications and Compliance: A reputable manufacturer will possess internationally recognized certifications such as ISO 9001 (Quality Management System), demonstrating a commitment to consistent quality control. Adherence to industry-specific standards like ASTM (e.g., ASTM C1116 for fiber-reinforced concrete) and CE marking (for European markets) indicates product performance and safety compliance. For example, our manufacturing facilities adhere strictly to ISO 9001:2015 standards, ensuring every batch of Polypropylene Fiber meets stringent quality benchmarks.

- Research and Development (R&D) Capabilities: Leading manufacturers invest in R&D to innovate and improve fiber properties, develop new applications, and offer enhanced performance. This indicates a forward-thinking approach and the ability to adapt to evolving industry needs. Look for evidence of ongoing material science research and product development initiatives.

- Production Capacity and Scalability: Ensure the manufacturer has the capacity to meet your volume requirements, from small pilot projects to large-scale industrial orders. Their ability to scale production efficiently without compromising quality is vital for maintaining project timelines. Our production lines are optimized for both high-volume output and flexible adjustments to accommodate diverse order sizes.

- Supply Chain Reliability and Logistics: A robust global supply chain ensures timely delivery and minimizes disruption. Evaluate their logistics network, lead times, and ability to handle international shipping. A reliable partner will have established relationships with freight forwarders and clear communication channels regarding order status. We leverage strategic partnerships and advanced logistics to guarantee on-time delivery globally, demonstrating decades of experience in managing complex supply chains.

- Technical Support and After-Sales Service: Access to expert technical support is invaluable. This includes assistance with product selection, dosage recommendations, application guidelines, and troubleshooting. A committed supplier will provide comprehensive pre-sales consultation and post-sales support, ensuring optimal product performance in your specific application. Our team of experienced engineers provides unparalleled technical support, from initial consultation to on-site guidance, ensuring you maximize the benefits of Polypropylene Fiber.

- Track Record and Industry Recognition: Review the manufacturer's client testimonials, case studies, and industry reputation. Partnerships with prominent companies or long service tenure in the industry can be strong indicators of reliability and performance. We proudly serve hundreds of clients across 50+ countries, with a service history spanning over two decades, solidifying our authoritative position in the industry.

Tailored Solutions for Unique Demands

Many applications require Polypropylene Fiber with specific characteristics. A top-tier manufacturer will offer customization options to meet these precise needs. This includes:

- Custom Denier and Length: Adjusting fiber thickness (denier) and cut length for optimal dispersion and performance in various matrices, from fine filtration to heavy-duty concrete.

- Surface Treatment: Applying specific coatings or surface modifications to enhance bonding with host materials or to impart properties like UV resistance or flame retardancy.

- Fiber Type Customization: Offering variations such as monofilament, fibrillated, or mesh configurations, each optimized for different performance requirements (e.g., crack control vs. impact resistance).

- Packaging Solutions: Providing specialized packaging (e.g., dissolvable bags for concrete batching, large bulk bags for industrial use) to enhance handling efficiency and reduce waste.

By carefully considering these factors, B2B buyers can forge strong, reliable partnerships with Polypropylene Fiber manufacturers who not only supply high-quality products but also provide the expertise and support necessary for successful project execution and long-term operational efficiency. Our commitment to transparent communication, robust quality assurance, and responsive customer service ensures that you receive precisely the Polypropylene Fiber solution you need, backed by decades of industry authority.

Real-World Impact: Polypropylene Fiber Application Case Studies

The theoretical advantages of Polypropylene Fiber translate into tangible benefits in real-world applications. These case studies highlight how this engineered material addresses complex challenges and delivers superior performance.

Case Study 1: Enhancing Durability of Industrial Warehouse Flooring

Challenge: A large logistics company needed to construct a new warehouse with a concrete floor capable of withstanding heavy forklift traffic, dynamic loads, and minimizing crack formation over its expected 30-year lifespan. Traditional steel mesh reinforcement was considered too labor-intensive and prone to corrosion in certain areas.

Solution: The project engineers opted for a concrete mix incorporating fibrillated Polypropylene Fiber at a dosage of 0.9 kg/m³. The fiber was introduced directly into the ready-mix concrete truck, ensuring uniform dispersion throughout the matrix. This approach allowed for continuous pouring without the need for placing and tying steel mesh, significantly accelerating the construction schedule.

Results: After five years of operation, the warehouse floor exhibits significantly fewer plastic shrinkage cracks compared to conventional concrete floors. The owner reported reduced maintenance requirements and improved overall surface integrity. The Polypropylene Fiber effectively controlled micro-cracking, improving the concrete's long-term abrasion resistance and extending the floor's service life, leading to substantial cost savings in repairs and operational downtime. The project was completed 15% faster than if traditional reinforcement had been used, demonstrating clear efficiency gains.

Case Study 2: Improving Corrosion Resistance in a Wastewater Treatment Plant

Challenge: A municipal wastewater treatment plant faced recurring issues with the degradation of concrete structures exposed to corrosive chemicals and microbial sulfuric acid attacks. Traditional steel reinforcement was susceptible to corrosion, leading to spalling and structural compromise, necessitating costly and frequent repairs.

Solution: For the new aeration tanks and secondary clarifiers, the project specified concrete reinforced with specially treated Polypropylene Fiber, combined with a high-performance chemical-resistant concrete mix design. The Polypropylene Fiber dosage was calibrated to provide optimal crack control and enhance the concrete's intrinsic resistance to chemical ingress, acting as a non-corrosive reinforcement.

Results: After 10 years, the Polypropylene Fiber-reinforced concrete structures show no signs of corrosion-induced cracking or spalling. The chemical inertness of the fiber ensures its integrity in the aggressive environment, while its crack-controlling properties prevent pathways for corrosive agents to penetrate the concrete. This has resulted in significantly extended service life of the tanks, drastically reducing maintenance costs and ensuring uninterrupted plant operations, representing a projected lifecycle cost saving of 40% over traditional methods.

Frequently Asked Questions (FAQ) about Polypropylene Fiber

Q: What is the typical dosage of Polypropylene Fiber in concrete?

A: The typical dosage for crack control in concrete ranges from 0.6 kg to 1.0 kg per cubic meter of concrete. However, specific applications like shotcrete or specialty mortars might require higher dosages. Always consult with the manufacturer's technical data sheets and conduct trial mixes for optimal results.

Q: Can Polypropylene Fiber replace steel reinforcement in concrete?

A: Polypropylene Fiber serves as a secondary reinforcement primarily for crack control, improving durability and toughness, especially against plastic shrinkage cracking and fire spalling. It generally cannot replace primary structural steel reinforcement (rebar) which carries tensile loads. However, in non-structural applications like slabs-on-grade, pavements, and precast elements, it can often replace or reduce the need for welded wire mesh, offering economic and practical advantages.

Q: Is Polypropylene Fiber environmentally friendly?

A: Polypropylene is a thermoplastic polymer that is recyclable, although the recycling of mixed materials like fiber-reinforced concrete presents challenges. The use of Polypropylene Fiber can contribute to sustainability by extending the lifespan of structures, reducing material consumption over time, and lowering maintenance needs, thus reducing overall environmental impact through resource efficiency.

Q: What is the shelf life of Polypropylene Fiber?

A: When stored correctly in a cool, dry place away from direct sunlight and extreme temperatures, Polypropylene Fiber typically has a shelf life of at least 2 to 3 years. Proper storage prevents degradation from UV exposure and maintains its physical properties.

Q: Does Polypropylene Fiber affect the workability of concrete?

A: At typical dosages, Polypropylene Fiber generally has a negligible effect on the slump or workability of concrete. In some cases, a minor adjustment to the superplasticizer might be considered for very sensitive mixes, but good mixing practices usually ensure homogeneous dispersion without issues.

Ensuring Seamless Supply: Delivery, Warranty, and Customer Support

For B2B operations, the quality of a product is only half the equation; the reliability of its delivery and the robustness of its supporting services are equally paramount. At our core, we understand that trust is built through consistent performance, transparent processes, and unwavering support.

Efficient Delivery Logistics and Global Reach

Our logistics network is engineered for efficiency and global reach, ensuring that your order of Polypropylene Fiber arrives precisely when and where you need it. With established distribution channels spanning continents, we manage complex international shipments with ease, offering various shipping options from sea freight to air cargo to meet your timeline and budget requirements. Our real-time tracking systems provide full visibility from dispatch to delivery, minimizing uncertainties and enabling precise project planning. We pride ourselves on a consistent 98% on-time delivery rate, reflecting our commitment to seamless supply chain operations and minimizing any potential project delays for our clients.

Commitment to Quality: Warranty and Comprehensive Support

Our confidence in the superior quality of our Polypropylene Fiber is underpinned by a clear and comprehensive warranty. We stand behind our products, ensuring they meet all specified technical parameters and perform as expected under recommended application conditions. In the unlikely event of any issue, our dedicated customer support team is readily available to provide prompt assistance and resolution.

- Technical Consultation: Our team of highly experienced engineers and material scientists offers expert guidance on product selection, optimal dosage rates, and best application practices for Polypropylene Fiber in your specific project. This pre-sales consultation ensures you choose the right product for maximum efficiency and performance.

- After-Sales Support: Beyond delivery, we provide ongoing support, including troubleshooting assistance, performance analysis, and detailed product documentation. Our commitment extends to helping you maximize the value and performance of our Polypropylene Fiber throughout its lifecycle.

- Custom Solutions Development: For unique project requirements, our R&D department collaborates closely with clients to develop tailored Polypropylene Fiber solutions, ensuring the material meets precise specifications and performance criteria.

Our decades of experience in the industry, coupled with hundreds of successful partnerships globally, speak to our authority and trustworthiness. When you choose us as your supplier for Polypropylene Fiber, you're not just purchasing a product; you're gaining a reliable partner committed to your project's success through unparalleled product quality, logistical precision, and dedicated customer care.

Conclusion: The Enduring Impact of Polypropylene Fiber

Polypropylene Fiber has firmly established itself as a cornerstone material in modern engineering and construction. Its unique combination of properties—including chemical inertness, high tensile strength-to-weight ratio, hydrophobicity, and excellent crack control capabilities—makes it an invaluable asset across a multitude of applications. From enhancing the durability of critical infrastructure like bridges and industrial floors to optimizing filtration systems and advanced textiles, Polypropylene Fiber continues to drive innovation and provide sustainable, cost-effective solutions.

As industries evolve and demand for high-performance, long-lasting, and resilient materials intensifies, the role of Polypropylene Fiber will only grow. Its ability to extend service life, reduce maintenance, and improve the overall efficiency of material systems directly contributes to lower lifecycle costs and a smaller environmental footprint. For B2B stakeholders, partnering with a manufacturer who upholds the highest standards of quality, innovation, and customer support is paramount to harnessing the full potential of this exceptional engineered fiber. The future of advanced materials undeniably features Polypropylene Fiber as a key enabler for more robust, sustainable, and high-performing solutions globally.

References

- ACI 544.1R-96 (Reapproved 2002). State-of-the-Art Report on Fiber Reinforced Concrete. American Concrete Institute, Farmington Hills, MI.

- ASTM C1116/C1116M-14. Standard Specification for Fiber-Reinforced Concrete. ASTM International, West Conshohocken, PA.

- Bentur, A., & Mindess, S. (2007). Fibre Reinforced Cementitious Composites. 2nd Edition. CRC Press.

- Fan, M., Satoh, T., & Saeki, T. (2012). Properties of Polypropylene Fiber Reinforced Concrete. Journal of Advanced Concrete Technology, 10(2), 52-61.

- Mehta, P. K., & Monteiro, P. J. M. (2014). Concrete: Microstructure, Properties, and Materials. 4th Edition. McGraw-Hill Education.

Pervious